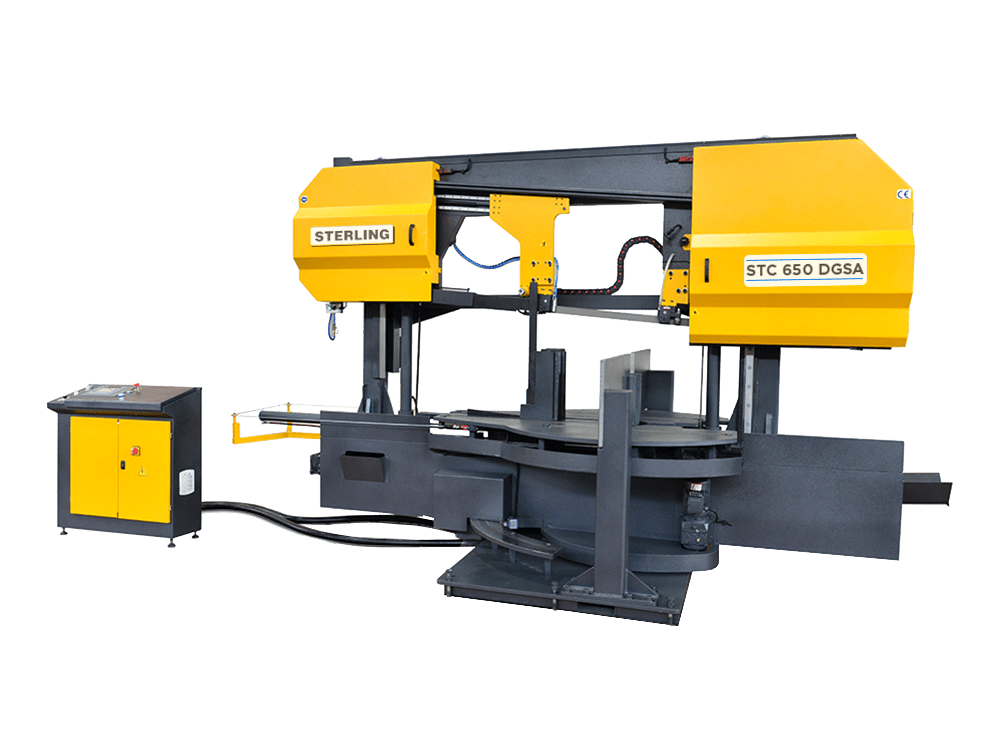

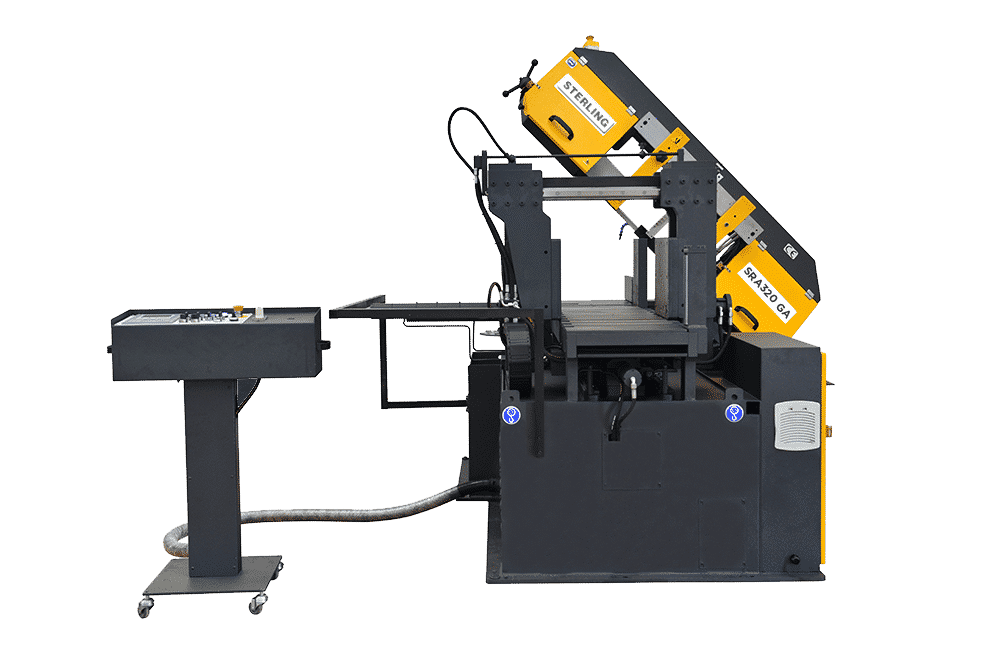

We offer an extensive range of industrial metal cutting bandsaws and metalworking machinery. From everyday single and double mitre bandsaws, horizontal bandsaws, right up to the twin column, fully automatic CNC machines. We also stock a range of vertical bandsaws too. Here in Hereford we have onsite facilities to craft the premium German Goldcut Bandsaw blades to suit your bandsaw, saving you time and money. Consumables ordered before 3:00 PM are generally despatched same day on a next-day carrier service to support your production with a bespoke supply solution.

Why Choose a Bandsaw?

A metal cutting bandsaw is essential for achieving accurate, consistent cuts across various materials, including mild steel, stainless steel, and aluminium. Compared to conventional cutting methods, bandsaws offer:

- Precision and consistency – Minimising material waste and improving finish quality.

- Efficiency in cutting operations – Enhancing productivity with high-speed cutting performance.

- Versatility – Available in horizontal and vertical configurations to suit different applications.

![Sterling STC540 GSA [Web]](https://selmach.com/wp-content/smush-webp/2015/08/Sterling-STC540-GSA-Web.png.webp)

![Sterling STC325 GA CNC [Web]](https://selmach.com/wp-content/smush-webp/2021/10/Sterling-STC325-GA-CNC-Web-1.png.webp)

![Sterling STC440 GA SERVO CNC [Web]](https://selmach.com/wp-content/smush-webp/2022/03/Sterling-STC440-GA-SERVO-CNC-Web.png.webp)