Morgan Rushworth Slat Cleaning Machine – 415V

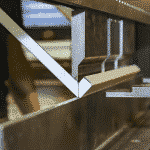

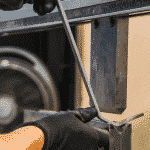

If you’re finding the slats on your Plasma or Laser table are so coated in slag material that it’s affecting accuracy, you’d typically need to replace the slats with fresh ones, which can be costly to do. The Morgan Rushworth Slat Cleaner can renew the existing slats by breaking off the slag leaving clean slats behind ready for more work. Extending the lifetime of the existing slats in a quick and efficient cleaning process.

Generally slats are getting changed several times in a year if you don’t use a proper cleaning machine. You can multiply the lifetime by using our machine.

| MODEL | MR SC1000 | MR SC1500 | |

| Max. Slat Thickness | mm | 4 | 5 |

| Dimensions | mm | 400 x 330 x 1510 | 458 x 298 x 1935 |

| Power | kw | 0.37 | 2.2 |

| Weight | kg | 27 | 35 |

Features

- You can multiply the lifetime of your laser slats and save lots of money in your pocket.

- Clean slats always help to get better cutting results.

- Spend only 10-15 mins for cleaning one laser bed!

- Supplied with a mobile trolley for moving and storage.

- Perfect for Plasma or Laser tables.

Options

If you’re find the slats on your Plasma or Laser table are so coated in slag material that it’s affecting accuracy, you’d typically need to replace the slats with fresh ones, which can be costly to do. The Morgan Rushworth Slat Cleaner can renew the existing slats by breaking off the slag leaving clean slats behind ready for more work. Extending the lifetime of the existing slats in a quick and efficient cleaning process.

Generally slats are getting changed several times in a year if you don’t use a proper cleaning machine. You can multiply the lifetime by using our machine.