Promotech PRO HP Hydraulic Portable Punching Machine

The Promotech PRO HP portable punching machines are ideal for the punching of I beams that are too large and heavy to be processed with fixed steelworkers and punching machines. There are also considerable time savings and consumable cost savings compared to traditional magnetic drilling machines as well as the advantage of being able to also punch square and slot holes too.

We also sell Punches and Dies for the Promotech range on our tooling website. Not sure which you need? Speak to our sales team.

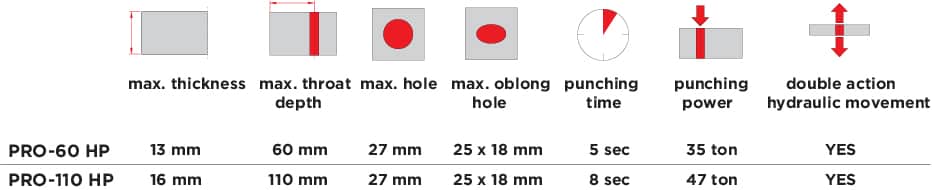

| MODEL | PRO-60 HP | PRO-110 HP | |

| STOCK CODE | 16550 | 16551 | |

| Rated Capacity | tonnes | 35 | 47 |

| Maximum Capacities | mm | 27 x 13 | 27 x 16 |

| Maximum Punching Thickness | mm | 13 | 16 |

| Punching Stroke | mm | 18 | 25 |

| Voltage | V | 230 | 230 |

| Throat Depth | mm | 60 | 110 |

| Weight | kg | 20 | 35 |

| Punching Time | sec | 5 | 8 |

| Return Time | sec | 2 | 2 |

| Power Supply | V / H | 230 /50 or 115 / 60 | 230 /50 or 115 / 60 |

| Power | W | 2000 | 2000 |

| Working Pressure | bar | 700 | 700 |

| Pump Output | L/min | 1.5 | 1.5 |

| Oil Capacity | L | 10 | 10 |

Features

- Fast clean punching of holes

- Almost noiseless operation

- Double action fully automated punching and return

- Intelligent control system with inching capability and automatic load detection

- Adjustable depth stop

- 5M hydraulic hose

- Wide range of punches and dies available in round, square and slot

Options

- Bench top stand

- Foot pedal control

- Hoist set with adjustable height and balancer

- Beam slide with adjustable depth

The Promotech portable punching machines are ideal for the punching of I beams that are too large and heavy to be processed with fixed steelworkers and punching machines. There are also considerable time savings and consumable cost savings compared to traditional magnetic drilling machines as well as the advantage of being able to punch square and slot holes.

The Hidden Dangers of Aluminium Dust from High-Speed Cutting

27th August 2024 by Dave Hargest

5 Key Factors to Consider when Purchasing Metalworking Machinery

11th March 2024 by Dave Hargest

4 Useful aspects of Sheet Metal Vacuum Lifters

21st December 2023 by Dave Hargest

5 Key Criteria to Consider for Vacuum Lifting

21st December 2023 by Dave Hargest

Lifting Magnets vs Vacuum Lifting

21st December 2023 by Dave Hargest

How Does an IPG LightWELD Laser Welder Compare to Traditional MIG or TIG Welding?

26th September 2023 by Dave Hargest

Laser Welding – Frequently Asked Questions

11th September 2023 by Dave Hargest

Coleg Gwent – Machinery for the next generation

14th November 2023 by Dave Hargest

Coleg Gwent is Wales' largest further education and one of the best-performing colleges, delivering a wide range of part-time and full-time academic and vocational courses to over 16,000 students annually... More

MMK Engineering – Bringing Profiling In-House

13th October 2023 by Dave Hargest

MMK Engineering Ltd, based in Devon, work across the full spectrum of engineering, from designing small components to assembling entire end-use products and machinery. We spoke to Rob Jeffrey, Design.. More

6IX Process Design Ltd uprate their machinery with Selmach

14th September 2022 by Dave Hargest

6IX Process Design Ltd, based in Somerset, are manufactures of stainless steel tanks, vessels and processing systems for the brewing and dairy industries. We spoke to Sam Cabell, Managing Director.. More

MR Industrial Services continued success with the help of Selmach Machinery

6th September 2022 by Dave Hargest

MR Industrial Services, based in Corby, Northamptonshire supply a range of architectural and industrial steelwork to the construction industry. We spoke to Carl Peters, Martyn Nimmo and William Adams to.. More