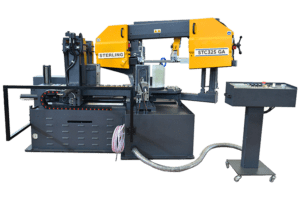

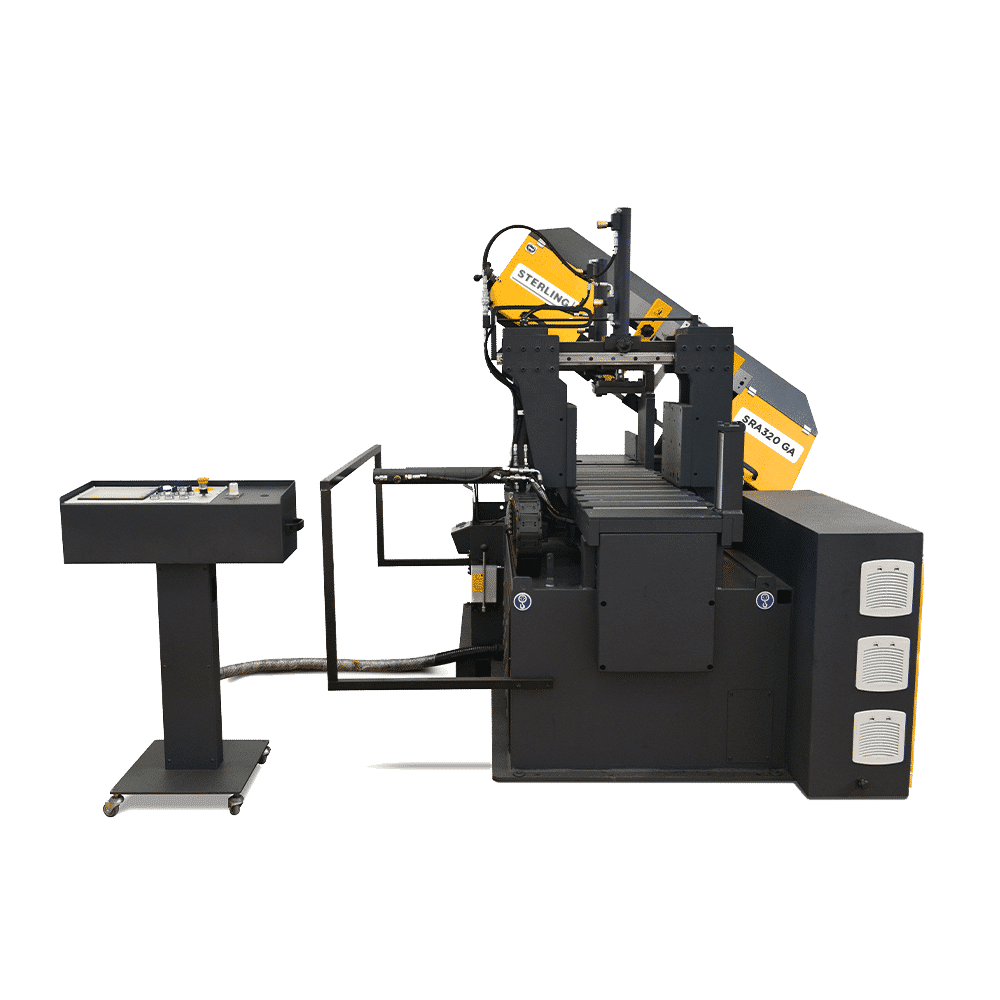

SRA320 GA CNC Servo Vice Feed Automatic Bandsaw

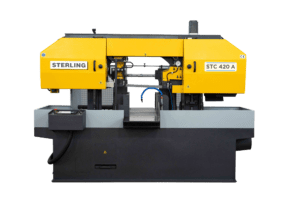

Sterling’s range of bandsaws are one of the leading brands in the metal cutting world. The SRA320 GA CNC series is designed to maximize our customers’ production of heavy metal, profile and pipe cuts in high-volume units with a fully automatic hydraulic feeding system. This a fully automatic machine in a pivot-action design ideally suited for cutting solid material, as well as pipes, profiles and beams in steel cutting.

The Omron Touchscreen CNC controller on this saw enables the user to set-up to 30 programmes with 50 steps each for automatic cutting, simply punch in your lengths and quantities, and let the saw do the work for you.

| MODEL | SRA320 GA CNC Servo Vice Feed | ||||

| Stock Code | 15267 | ||||

| Capacity | 90° | 30° | 45° | 60° | |

| ◯ Round | mm | 320 | 300 | 260 | 160 |

| □ Flat | mm | 320 | 250 | 180 | 150 |

| ▭ Square | mm | 350 x 320 | 300 x 200 | 250 x 180 | 150 x 150 |

| Bed Height | 740 | ||||

| Main Drive Motor | kW | 2.2 | |||

| Cutting Speeds | m/min. | 20 – 100 | |||

| Blade Dimensions | mm | 3660x27x0.9 | |||

| Tolerances | mm | 0.1 | |||

| CNC Controller | Omron Touchscreen | ||||

| Program | 30 Programmes – 50 Steps | ||||

| Stroke Length | mm | 700 | |||

| Remnant Piece | mm | 275 (Fully Automatic) 65 (Manual) | |||

| Max. Feed | mm | 9999 | |||

| Length | mm | 2100 | |||

| Width | mm | 2100 | |||

| Height | mm | 1810 | |||

| Weight | kg | 2310 | |||

| Operation | Automatic | ||||

| Vice | Hydraulic | ||||

| Vice Feed | Servo (1kW) | ||||

Features

- Pivot-Action

- Fully automatic NC

- Hydromechanical Blade Tension

- Inverter drive providing infinitely variable blade speed

- Automatic bow return

- Hydraulic vice

- Servo feeding with 700mm stroke

- User-friendly Omron touch screen

- Highly efficient gearbox

- CNC control panel (30 Programs – 50 steps)

- Sensitive cutting pressure regulation

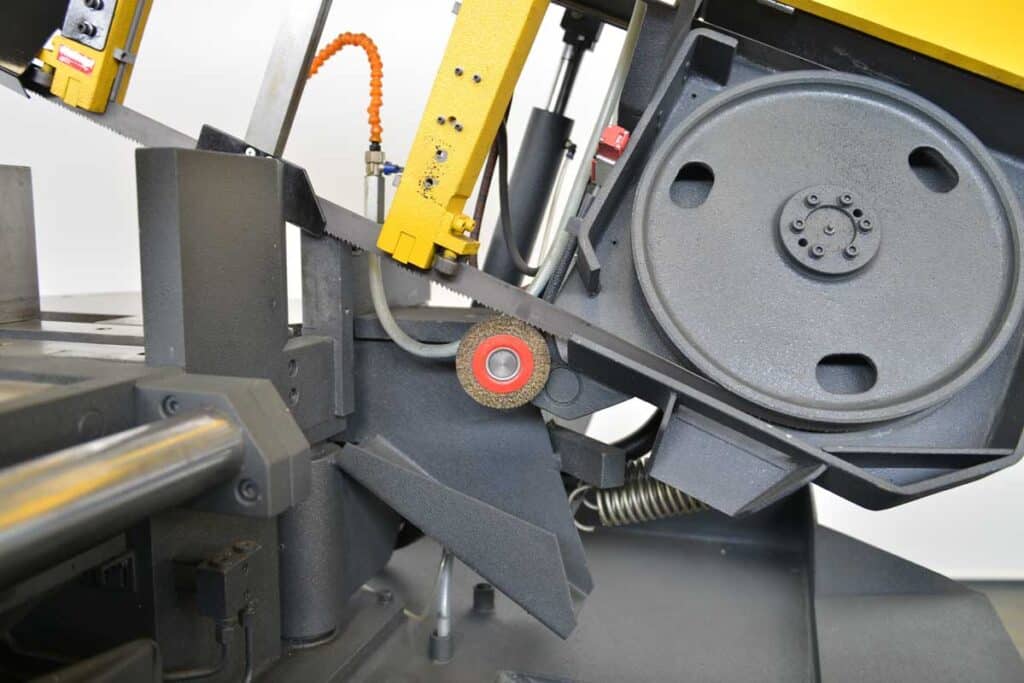

- Swarf brush

- Chip Conveyor

- Carbide blade guides

- Flood Coolant system

Options

- Hydraulic blade tension

- Hydraulic top clamps

- Spray mist lubrication

- Hexagonal Vice for bundle cutting

- Roller track and measuring systems

Sterling’s range of bandsaws are one of the leading brands in the metal cutting world. The SRA320 GA CNC series is designed to maximize our customers’ production of heavy metal, profile and pipe cuts in high-volume units with a fully automatic hydraulic feeding system. This a fully automatic machine in a pivot-action design ideally suited for cutting solid material, as well as pipes, profiles and beams in steel cutting.

The Omron Touchscreen CNC controller on this saw enables the user to set-up to 30 programmes with 50 steps each for automatic cutting, simply punch in your lengths and quantities, and let the saw do the work for you.

A built-in flood coolant system helps to not only prolong blade life, but assists with a cleaner cut, preventing overheating and warping of blades. The hydraulic gravity down feed allows you complete control of the speed of the cut, ensuring the drop of the blade suits to the material that you are cutting, with the automatic stop, the blade will stop spinning once the cut is complete, allowing for safer worker interaction.

Ideal for cutting round, square or rectangular section, bandsaws like this Sterling SRA320 GA CNC are the mainstay of virtually any fabrication shop in the UK. We offer a wide range of Sterling and Bianco Bandsaws, to fit with your cutting requirements, look at the rest of the range here.

We can also supply blades and coolant too, these can be purchased directly off our tooling website. All of our Saws are supplied with a starter set of our Goldcut Blades, we will discuss with you the material you will be cutting to ensure they will meet your requirements and a free container of coolant, so your new saw is ready to begin cutting straight away as soon as it’s delivered to you!