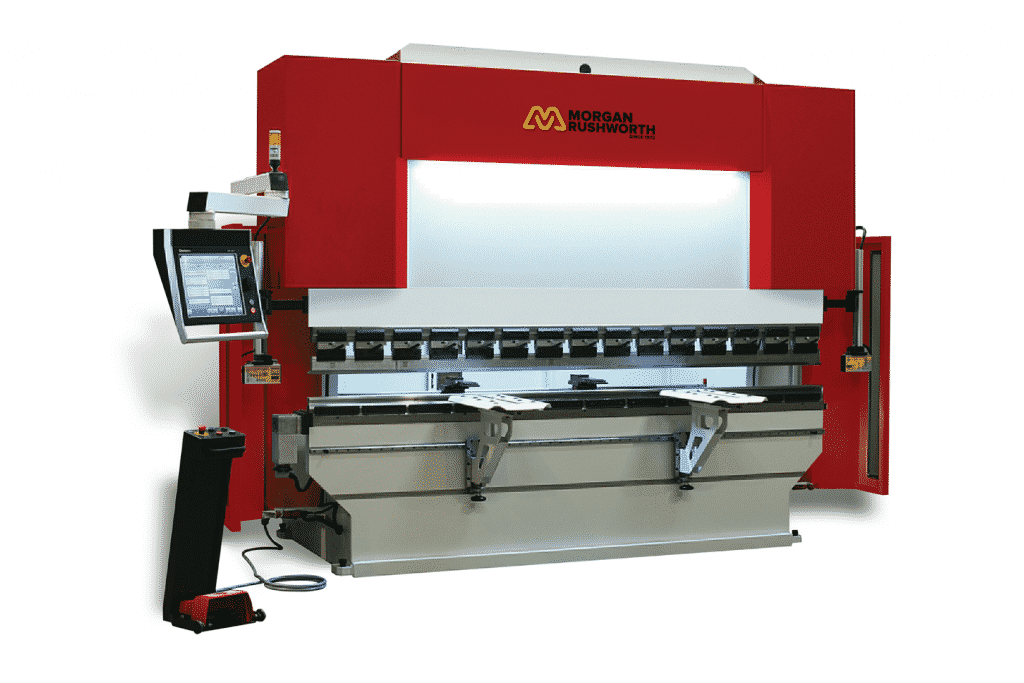

The PBS CNC Press Brake

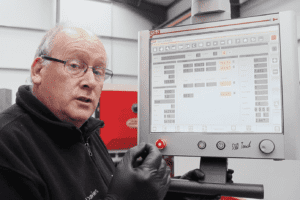

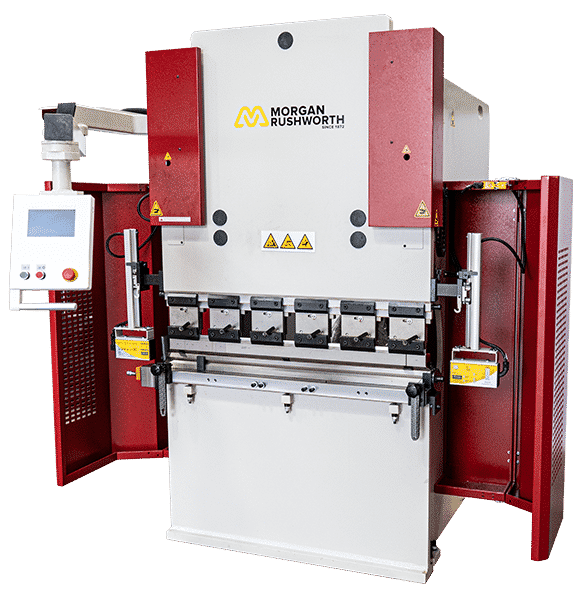

Capable and cost effective, the PBS CNC hydraulic series offer CNC control in the form of the easy to use, intuitive new ESA 630 touch screen CNC controller, enabling offline programming via PC. The CNC software also features a large tool library and the ability to perform 2D auto bend sequence computations. The software enables full offline 2D graphical view programming, transferrable to the controller via USB flashdrive.

Introducing automation

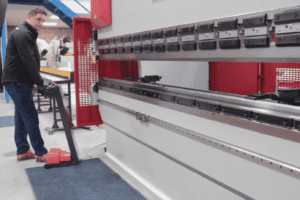

The PBS CNC series offers the ability to perform complex operations easily, ideal for high volume production and consistent, accurate work.

With three axes as standard, (Y1, Y2 & X) the PBS CNC machines have the capacity to go up to seven axes thanks to the CNC Z and R axes on the back gauge and crowning systems. The Y1 and Y2 axes are both fully synchronised, accurate to 0.01mm with proportional valve technology. The range also boasts a fast CNC back gauge with AC servo drive and Euro style top clamps with intermediaries and quick release tool clamps.

Heavy Duty intelligence

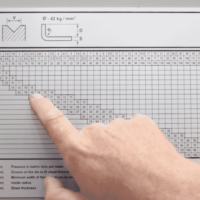

The PBS CNC range of press brakes is available in an impressive range of tonnage options and all feature a strong rigid welded monoblock frame to withstand deflection under load. A wide range of accessories are available to fully tailor the PBS CNC to your own unique requirements. The range spans 1250mm X 40T all the way up to 4100mm X 300T capacities to ensure that, whatever your fabrication needs, the PBS CNC press brake can deliver.

Optional extras

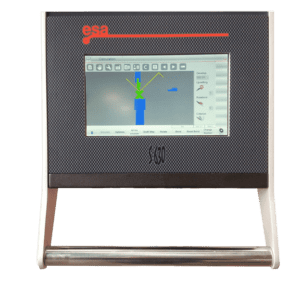

Extras for the PBS CNC series of press brakes include either manual or CNC controlled bottom tool crowning, extra backgauge fingers, extra front support arms and the S660 3D colour graphical CNC controller.

Specifications overview

- Bend accuracy up to five times more accurate than conventional press brakes

- Hydraulic ram travel guided in low friction slideways

- Ventilated electrical cabinet.

- Rear guard with photo cell safety beam

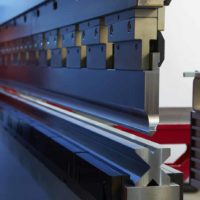

- Sectionalised goose neck top tool and Sectionalised multi-vee bottom die

- Fiessler AKAS laser front light guards

Find out more about the PBS CNC Press Brake here

![Morgan Rushworth PB Press Brake [Web]](https://selmach.com/wp-content/uploads/2015/09/Morgan-Rushworth-PB-Press-Brake-Web-300x200.png)