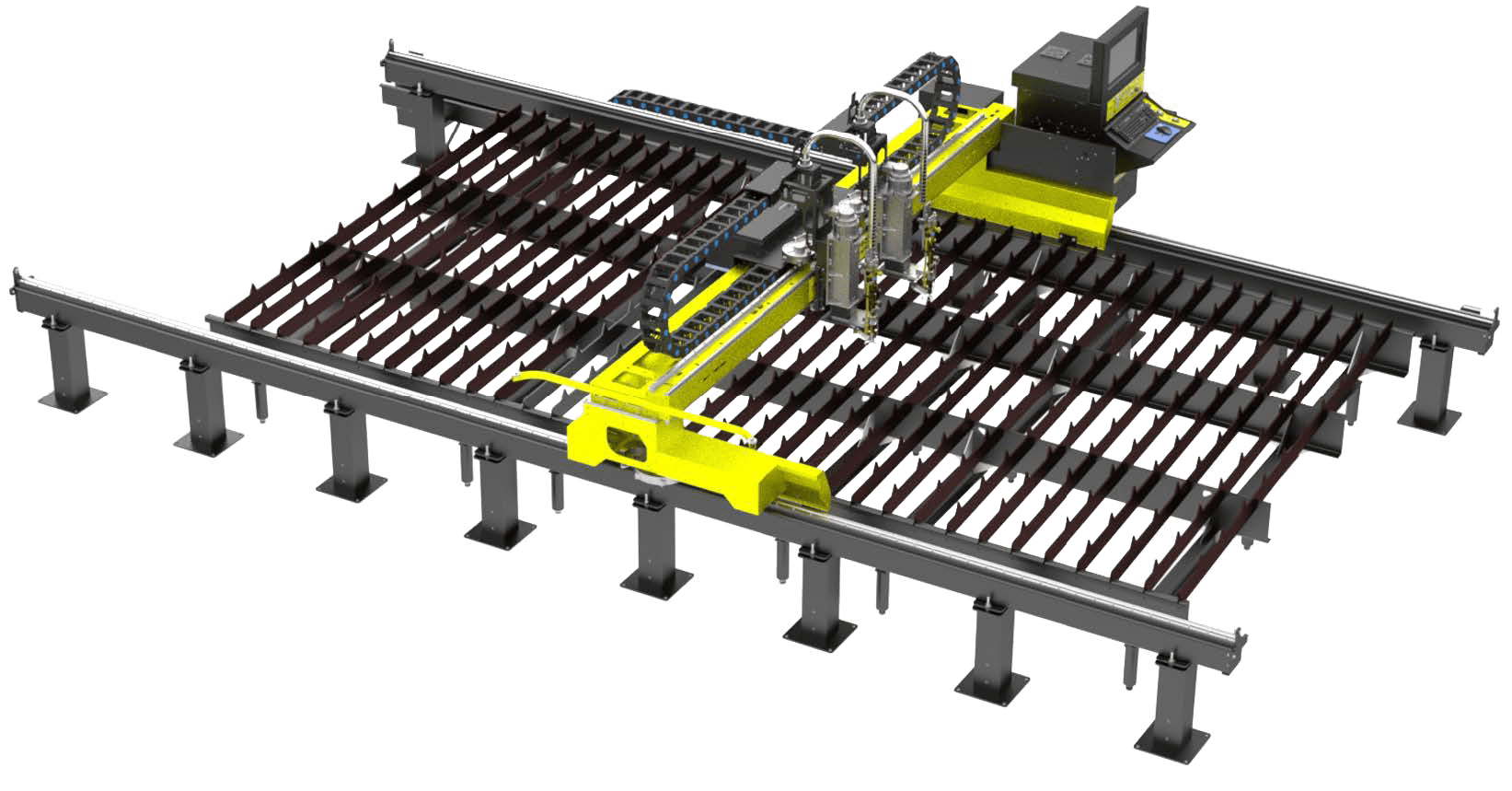

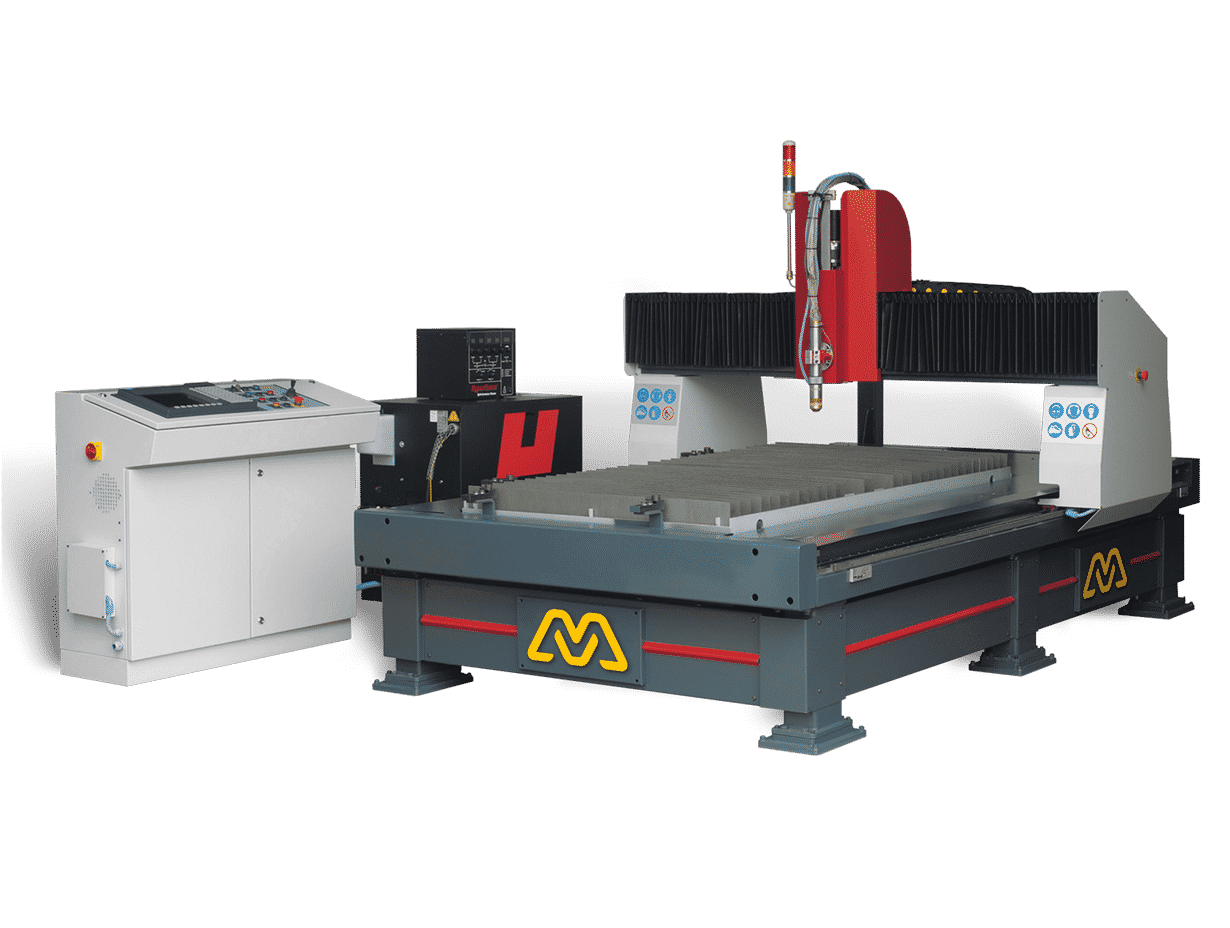

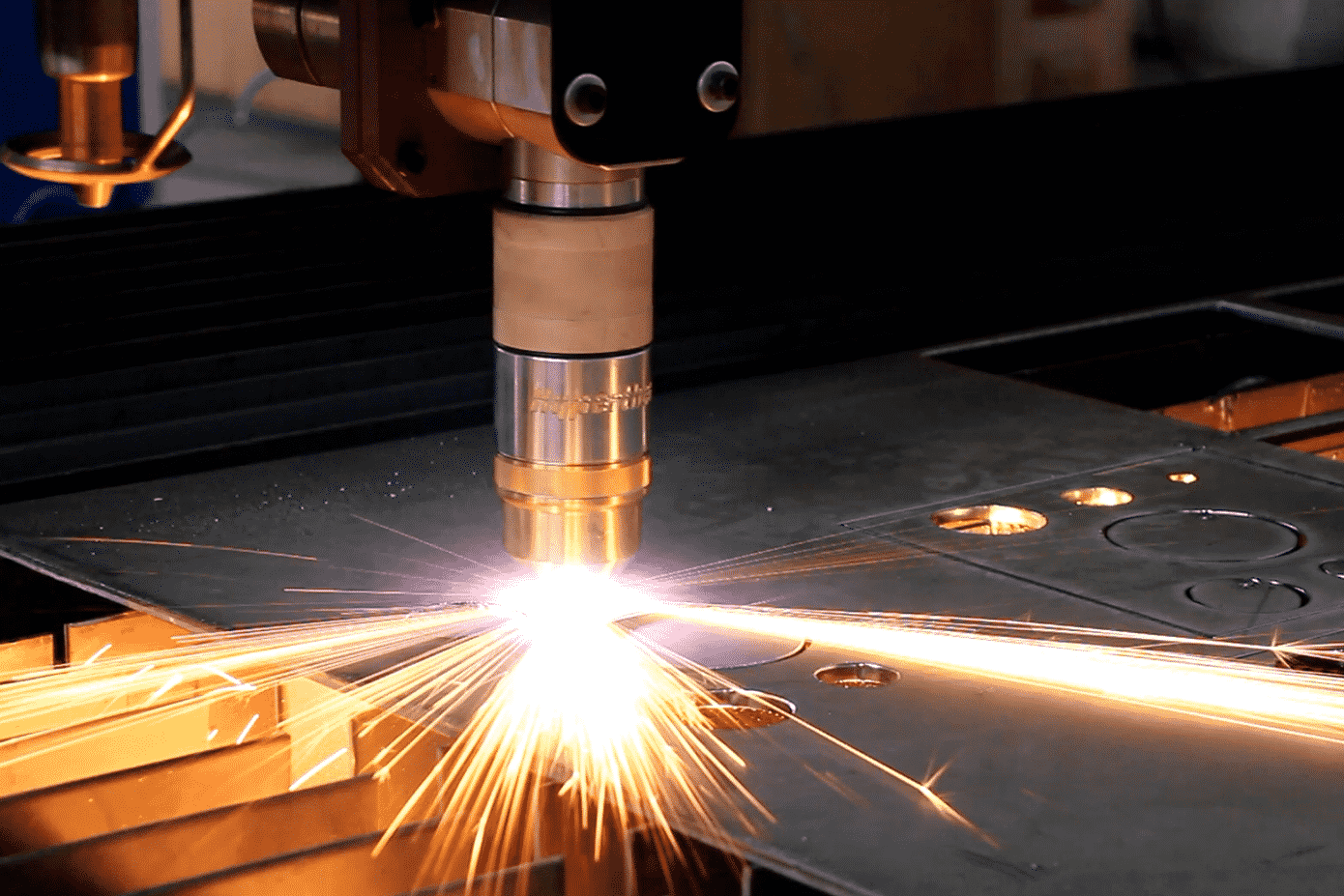

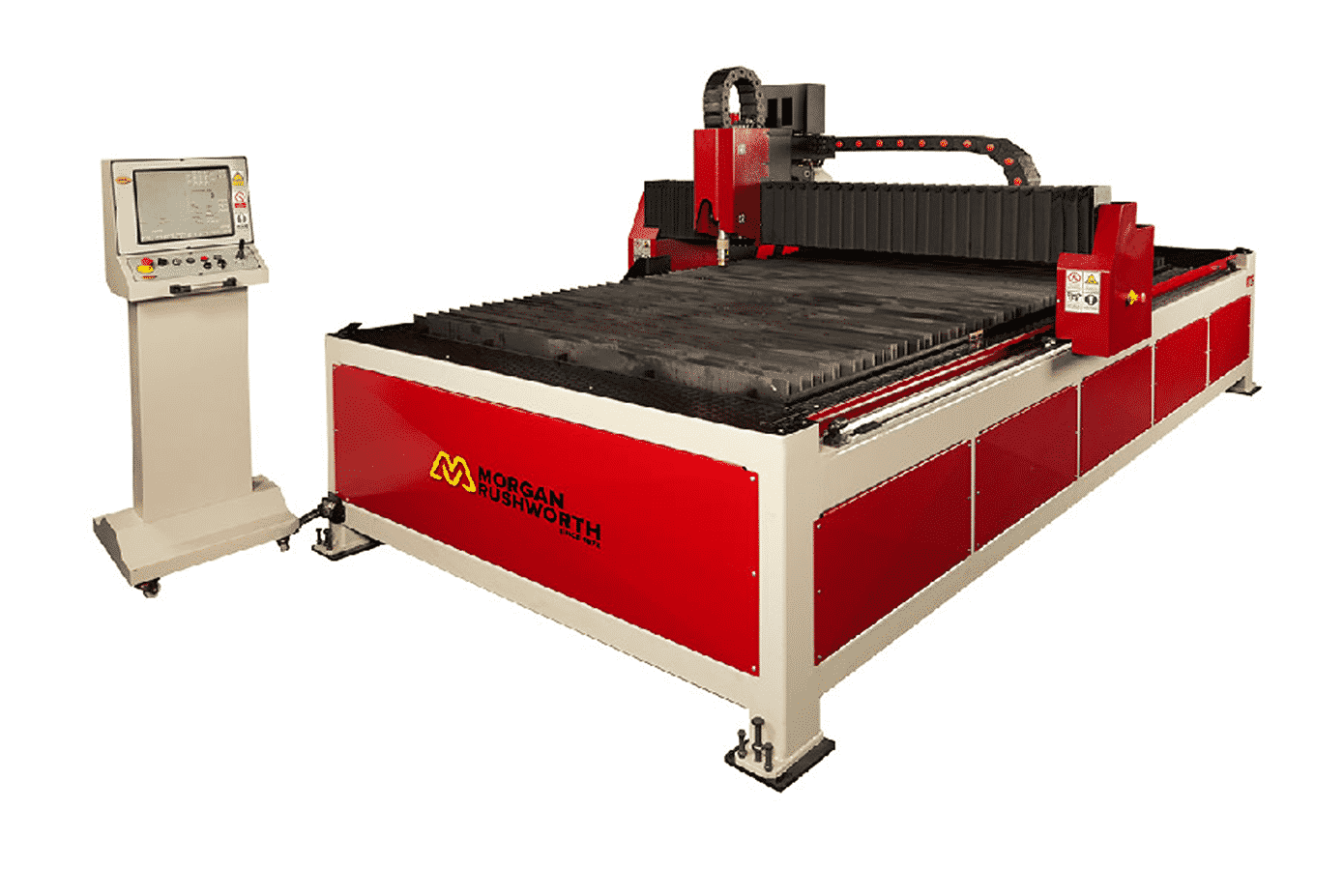

Our very own Morgan Rushworth range combine with the Ajan plasma and Hypertherm plasma to deliver the very best plasma cutting machinery our industry has to offer. We pride ourselves in being to offer a wide range of sheet and plate metal machinery to suit all of your fabrication requirements. With years of experience and knowledge of the industry and an in-depth understanding of a wide range of applications, our sales team strive to recommend the most suitable machinery for your specific requirement.

CNC Plasma Cutter Machinery

Our range of hypertherm plasma cutting, Morgan Rushworth machines and the Ajan plasma can all be demonstrated at any of our three branches and as part of our first class after-sales service, our trained engineers are on hand to provide technical advice and can rapidly respond to any issues that may arise. For more technical applications and training on the machine controls and handling is available from our trained engineers.

![Morgan Rushworth SPM - Tube Plasma [Web]](https://selmach.com/wp-content/uploads/2022/09/Morgan-Rushworth-SPM-Tube-Plasma-Web.png)