Morgan Rushworth PBXS CNC Hydraulic Press Brake

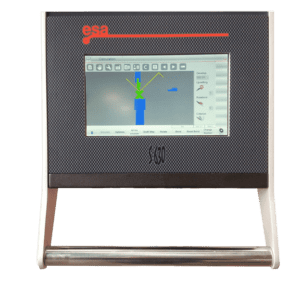

The Morgan Rushworth PBXS CNC press brakes are fitted with the ESA VIS-875W CNC control featuring a 21” touch screen and both numerical and 2D graphical program entry. These models feature 4-axis CNC control of the left and right ram cylinders, the back gauge depth and back gauge height.

The range covers models from 40 tonnes through to 1000 tonnes capacity with bending lengths from 1250mm up to 8100mm in the standard design.

A comprehensive range of options are available to fully tailor the machine to requirements.

| MODEL | STOCK CODE | BENDING POWER | BENDING LENGTH | DIST BETWEEN COLUMNS | Y RAPID SPEED | Y WORKING SPEED | Y RETURN SPEED | TRAVEL IN X AXIS | SPEED OF X AXIS | TRAVEL IN R AXIS (OPTIONAL) | SPEED OF R AXIS (OPTIONAL) | NO OF BACK GAUGE FINGERS | NO OF SHEET SUPPORT ARMS | OIL CAPACITY | MOTOR POWER | STROKE | DAYLIGHT | THROAT DEPTH | TABLE HEIGHT | TABLE WIDTH | PIT DEPTH 1 | PIT DEPTH 2 | LENGTH | WIDTH | HEIGHT | WEIGHT |

| Tonne | A mm | B mm | mm/sec | mm/sec | mm/sec | mm/sec | mm/sec | mm/sec | mm/sec | Litre | kw | C mm | D mm | E mm | F mm | G mm | E1 mm | E2 mm | L mm | W mm | H mm | kg | ||||

| PBXS CNC 1250/40 | M5200 | 40 | 1250 | 1070 | 160 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 80 | 8 | 215 | 455 | 410 | 800 | 60 | 3000 | 2670 | 2250 | 3300 | ||

| PBXS CNC 2100/60 | M5201 | 60 | 2100 | 1600 | 150 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 140 | 9.5 | 210 | 475 | 410 | 880 | 60 | 3850 | 2780 | 2542 | 5400 | ||

| PBXS CNC 2600/60 | M5202 | 60 | 2600 | 2050 | 160 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 140 | 9.5 | 210 | 475 | 410 | 880 | 60 | 4350 | 2780 | 2542 | 6200 | ||

| PBXS CNC 2600/90 | M5203 | 90 | 2600 | 2050 | 150 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 140 | 11.5 | 260 | 540 | 410 | 880 | 60 | 4350 | 2780 | 2605 | 7100 | ||

| PBXS CNC 3100/90 | M5204 | 90 | 3100 | 2550 | 160 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 140 | 11.5 | 260 | 530 | 410 | 880 | 60 | 4850 | 2790 | 2605 | 7900 | ||

| PBXS CNC 3100/120 | M5205 | 120 | 3100 | 2550 | 160 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 140 | 15 | 260 | 540 | 410 | 880 | 60 | 4850 | 2790 | 2905 | 8400 | ||

| PBXS CNC 3100/160 | M5206 | 160 | 3100 | 2550 | 160 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 19 | 260 | 540 | 410 | 880 | 60 | 4850 | 2800 | 2905 | 9700 | ||

| PBXS CNC 3100/200 | M5207 | 200 | 3100 | 2550 | 150 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 22.5 | 260 | 530 | 410 | 880 | 90 | 4850 | 2800 | 2905 | 10000 | ||

| PBXS CNC 3100/240 | M5208 | 240 | 3100 | 2550 | 130 | 10 | 120 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 26 | 260 | 530 | 410 | 880 | 90 | 4850 | 2810 | 2905 | 11000 | ||

| PBXS CNC 3100/300 | M5209 | 300 | 3100 | 2550 | 110 | 8 | 100 | 1000 | 350 | 160 | 240 | 2 | 2 | 280 | 26 | 320 | 660 | 500 | 905 | 380 | 4850 | 3015 | 3150 | 15000 | ||

| PBXS CNC 3100/440 | M5256 | 440 | 3100 | 2550 | 80 | 8 | 70 | 1000 | 350 | 160 | 240 | 2 | 2 | 450 | 34 | 320 | 575 | 500 | 1005 | 450 | 4850 | 3260 | 3400 | 2200 | ||

| PBXS CNC 3700/120 | M5210 | 120 | 3700 | 3250 | 170 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 15 | 260 | 530 | 410 | 870 | 60 | 5450 | 2830 | 2905 | 9400 | ||

| PBXS CNC 3700/160 | M5211 | 160 | 3700 | 3250 | 170 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 19 | 260 | 530 | 410 | 880 | 60 | 5450 | 2800 | 2905 | 10700 | ||

| PBXS CNC 3700/200 | M5212 | 200 | 3700 | 3250 | 150 | 10 | 130 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 22.5 | 260 | 530 | 410 | 880 | 90 | 5450 | 2800 | 2905 | 11200 | ||

| PBXS CNC 3700/240 | M5213 | 240 | 3700 | 3250 | 140 | 10 | 120 | 1000 | 350 | 160 | 240 | 2 | 2 | 210 | 26 | 260 | 530 | 410 | 880 | 90 | 5450 | 2810 | 2905 | 13500 | ||

| PBXS CNC 3700/300 | M5214 | 300 | 3700 | 3250 | 120 | 8 | 110 | 1000 | 350 | 160 | 240 | 2 | 2 | 280 | 26 | 320 | 635 | 500 | 980 | 280 | 5450 | 3020 | 3200 | 17000 | ||

| PBXS CNC 4100/160 | M5215 | 160 | 4100 | 3550 | 170 | 10 | 100 | 1000 | 350 | 160 | 240 | 4 | 2 | 210 | 19 | 260 | 530 | 410 | 880 | 60 | 5850 | 2800 | 2905 | 12000 | ||

| PBXS CNC 4100/200 | M5216 | 200 | 4100 | 3550 | 160 | 10 | 110 | 1000 | 350 | 160 | 240 | 4 | 2 | 210 | 22.5 | 260 | 530 | 410 | 880 | 90 | 5850 | 2800 | 2905 | 12500 | ||

| PBXS CNC 4100/240 | M5217 | 240 | 4100 | 3550 | 150 | 10 | 100 | 1000 | 350 | 160 | 240 | 4 | 2 | 210 | 26 | 260 | 530 | 410 | 880 | 90 | 5850 | 2810 | 2905 | 14000 | ||

| PBXS CNC 4100/300 | M5218 | 300 | 4100 | 3550 | 120 | 8 | 90 | 1000 | 350 | 160 | 240 | 4 | 2 | 280 | 26 | 320 | 635 | 500 | 980 | 280 | 5850 | 3020 | 3200 | 18500 | ||

| PBXS CNC 4100/440 | M5219 | 440 | 4100 | 3550 | 80 | 8 | 70 | 1000 | 350 | 160 | 240 | 4 | 2 | 450 | 34 | 320 | 590 | 500 | 955 | 380 | 5850 | 3435 | 3350 | 26000 | ||

| PBXS CNC 6100/160 | M5220 | 160 | 6100 | 5100 | 140 | 10 | 100 | 1000 | 350 | 160 | 240 | 4 | 4 | 240 | 19 | 260 | 510 | 500 | 1000 | 90 | 7850 | 3160 | 2850 | 20000 | ||

| PBXS CNC 6100/240 | M5221 | 240 | 6100 | 5100 | 140 | 10 | 100 | 1000 | 350 | 160 | 240 | 4 | 4 | 300 | 26 | 260 | 500 | 500 | 1100 | 90 | 7850 | 3160 | 3000 | 25000 | ||

| PBXS CNC 6100/300 | M5222 | 300 | 6100 | 5100 | 120 | 8 | 70 | 1000 | 350 | 160 | 240 | 4 | 4 | 300 | 26 | 320 | 560 | 500 | 1115 | 200 | 7850 | 3260 | 3280 | 30000 | ||

| PBXS CNC 6100/380 | M5223 | 380 | 6100 | 5100 | 90 | 8 | 70 | 1000 | 350 | 160 | 240 | 4 | 4 | 450 | 34 | 320 | 570 | 500 | 1100 | 240 | 7850 | 3410 | 3255 | 35000 | ||

| PBXS CNC 6100/440 | M5224 | 440 | 6100 | 5100 | 90 | 8 | 70 | 1000 | 350 | 160 | 240 | 4 | 4 | 450 | 34 | 320 | 570 | 500 | 1100 | 280 | 7850 | 3450 | 3700 | 39000 | ||

| PBXS CNC 6100/500 | M5225 | 500 | 6100 | 5100 | 80 | 8 | 70 | 1000 | 350 | 160 | 240 | 4 | 4 | 450 | 41 | 340 | 530 | 500 | 815 | 380 | 250 | 800 | 7850 | 3550 | 3500 | 48000 |

| PBXS CNC 6100/600 | M5226 | 600 | 6100 | 5100 | 80 | 7 | 70 | 1000 | 350 | 160 | 240 | 4 | 4 | 500 | 41 | 360 | 620 | 500 | 1050 | 380 | 370 | 1150 | 7850 | 3600 | 4100 | 55000 |

| PBXS CNC 6100/800 | M5255 | 800 | 6100 | 5100 | 70 | 6 | 60 | 1000 | 350 | 160 | 240 | 4 | 4 | 700 | 49 | 500 | 750 | 750 | 1050 | 500 | 600 | 1200 | 7850 | 4000 | 4750 | 70000 |

| PBXS CNC 6100/1000 | M5257 | 1000 | 6100 | 5100 | 70 | 6 | 60 | 1000 | 350 | 160 | 240 | 4 | 4 | 860 | 59 | 500 | 750 | 750 | 800 | 500 | 700 | 1500 | 7850 | 4100 | 4900 | 80000 |

| PBXS CNC 8100/1000 | M5258 | 1000 | 8100 | 6050 | 70 | 5 | 60 | 1000 | 350 | 160 | 240 | 4 | 4 | 860 | 59 | 500 | 750 | 750 | 800 | 500 | 700 | 1900 | 9850 | 4200 | 5000 | 95000 |

Features

- ESA S875 multi-axis CNC control with numerical and 2D graphical programming and 2D or 3D visualisation, mounted on pendant arm

- Ideal for complex multi bending operations, especially where volume production with accurate repeatability is required

- Fully synchronised CNC control for leftand right upper beam cylinder position – Y1 + Y2 axis

- CNC control for backgauge depth – X axis

- Manual adjustment of backgauge height – R axis

- Manual side to side adjustment of backgauge fingers – Z axis

- AKAS laser tooling guards for enhanced ease of use

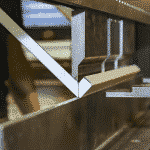

- Euro style quick release top tool holders with intermediate pieces including wedges for crowning, Sectionalised goose neck top tool and multi vee bottom die

- Strong rigid welded mono block frame able to withstand deflection under maximum load

- High precision linear scales for measurement of stroke depth mounted on side frames rather than top beam to prevent any distortion in accuracy as beam

comes under load - Hydraulic ram travel guided in low friction slideways

- Large open height and generous ram stroke

- Deep reinforced throat in side frames

- High approach and return speeds for production bending

- Front support arms with flip stop, adjustable on a linear rail

- Dual foot switch console with emergency stop

- Electrically interlocked side guards

- Electrically interlocked rear access door

Options

- Cybelec ModEva 12S 3D graphical CNC control

- Cybelec ModEva 15S 3D graphical CNC control

- Cybelec ModEva 15S 3D graphical touchscreen CNC control

- Delem DA66W 2D graphical CNC control

- Delem DA66T 2D graphical touchscreen CNC control

- Delem DA69W 3D graphical CNC control

- Delem DA69T 3D graphical touchscreen CNC control

- X1 + X2, R or R1 + R2, Z or Z1 + Z2 axes

- Additional Back Gauge Finger X Axis Backgauge

- Additional Back Gauge Finger X, R Axis Backgauge

- Hydraulic Release Top and Bottom Tooling Clamping System

- Mechanical anti deflection table

- CNC motorized anti deflection table

- Brush table for front support arms

- Additional sliding front support arms

- Sheet follower support arms controlled by the CNC

- Parking area for sheet follower support arms – one per side

- Laser Angle Measuring System

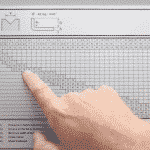

The Morgan Rushworth PBXS CNC hydraulic press brakes are fitted with the ESA S875 CNC Control featuring a 21” touch screen and both numerical and 2D graphical program entry. While data input into the CNC Control is very rapid, there is also the option of preparing the production off line on a PC with the software provided, enabling feasibility checks prior to production.

All axes are fully synchronised and accurate 0.01mm utilising proportional valve technology. Monoblock welded steel frame ensures minimum deflection under maximum load.

The range covers models from 40 tonnes through to 1000 tonnes capacity with bending lengths from 1250mm up to 8100mm in the standard design.

A comprehensive range of options are available to fully tailor the machine to requirements.