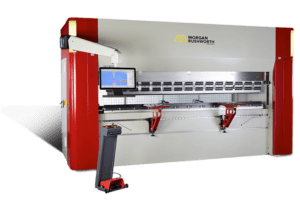

Morgan Rushworth XPH Hybrid CNC Press Brake

The Morgan Rushworth XPH range of hybrid press brakes are designed with an individual electro-hydraulic servo drive system for each of the left and right cylinders. With this system the hydraulics run on demand when the foot pedal is activated, rather than having a pump running continuously. This results in lower energy usage than a standard hydraulic machine as well as faster cycle times and extremely high accuracy.

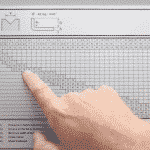

All models are fitted with the ESA VIS-875W CNC control featuring a 21” touch screen and both numerical and 2D graphical program entry. These machines follow a rigorous design and manufacturing process to ensure minimum deflection of the machine frame under maximum working pressure. AKAS laser tooling guards are standard and offer a vastly improved operator experience without compromising safety. A comprehensive range of options are available to fully tailor the machine to requirements including 6-axis or 8-axis configurations.

| MODEL | STOCK CODE | BENDING POWER | BENDING LENGTH | DIST BETWEEN COLUMNS | Y APPROACH SPEED | Y WORKING SPEED | Y RETURN SPEED | TRAVEL IN X AXIS | X AXIS SPEED | TRAVEL IN R AXIS | R AXIS SPEED | NO OF BACK GAUGE FINGERS | NO OF SHEET SUPPORT ARMS | OIL CAPACITY | MOTOR POWER | STROKE | DAYLIGHT | THROAT DEPTH | TABLE HEIGHT | TABLE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT |

| Tonne | A mm | B mm | mm/sec | mm/sec | mm/sec | mm | mm/sec | mm | mm/sec | litres | kw | C mm | D mm | E mm | F mm | G mm | L mm | W mm | H mm | kg | ||||

| XPH 3100/120 | M5340 | 120 | 3100 | 2550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 34.5 | 2 x 6.0 | 260 | 530 | 410 | 880 | 60 | 4,850 | 2,790 | 2,905 | 8,400 |

| XPH 3100/160 | M5341 | 160 | 3100 | 2550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 60 | 4,850 | 2,800 | 2,905 | 9,700 |

| XPH 3100/200 | M5342 | 200 | 3100 | 2550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 4,850 | 2,800 | 2,905 | 10,000 |

| XPH 3100/240 | M5343 | 240 | 3100 | 2550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 4,850 | 2,810 | 2,905 | 11,000 |

| XPH 3100/300 | M5344 | 300 | 3100 | 2550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 320 | 660 | 410 | 905 | 380 | 4,850 | 3,015 | 3,150 | 15,000 |

| XPH 3700/160 | M5345 | 160 | 3700 | 3250 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 60 | 5,450 | 2,800 | 2,905 | 10,700 |

| XPH 3700/200 | M5346 | 200 | 3700 | 3250 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 5,450 | 2,800 | 2,905 | 11,200 |

| XPH 3700/240 | M5347 | 240 | 3700 | 3250 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 5,450 | 2,810 | 2,905 | 13,500 |

| XPH 3700/300 | M5348 | 300 | 3700 | 3250 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 2 | 2 | 2 x 55 | 2 x 9.2 | 320 | 635 | 410 | 980 | 280 | 5,450 | 3,020 | 3,200 | 17,000 |

| XPH 4100/160 | M5349 | 160 | 4100 | 3550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 4 | 4 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 5,850 | 2,800 | 2,905 | 12,000 |

| XPH 4100/200 | M5350 | 200 | 4100 | 3550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 4 | 4 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 5,850 | 2,800 | 2,905 | 12,500 |

| XPH 4100/240 | M5351 | 240 | 4100 | 3550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 4 | 4 | 2 x 55 | 2 x 9.2 | 260 | 530 | 410 | 880 | 90 | 5,850 | 2,810 | 2,905 | 14,000 |

| XPH 4100/300 | M5352 | 300 | 4100 | 3550 | 200 | 10 | 200 | 750 | 350 | 160 | 240 | 4 | 4 | 2 x 55 | 2 x 9.2 | 320 | 635 | 410 | 980 | 280 | 5,850 | 3,020 | 3,200 | 18,500 |

Features

- Approximately 60% less energy use when idle

- Approximately 45% less energy use during bending

- Approximately 30% faster cycle times

- ESA VIS-875W multi-axis CNC control with numerical and 2D graphical programming and 2D or 3D visualisation

- Control mounted on height adjustable pendant arm

- Fully synchronised CNC control of left and right upper beam cylinder position – Y1 + Y2 axis

- CNC control of back gauge depth – X axis

- CNC control of back gauge height – R axis

- Manual side to side movement of back gauge fingers – Z axis

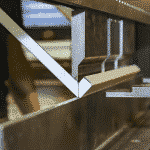

- Euro style top tool holders with intermediates

- Sectionalised goose neck top tool and multi vee bottom die

- CNC bottom tool crowning system

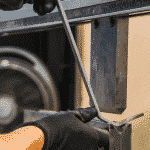

- AKAS laser tooling guards for enhanced ease of use

Options

- Optional off line ESA Bend 3D Software with Control Viewer

- Independent CNC control of side to side movement of back gauge fingers – Z1 + Z2 axis

- Independent CNC tower back gauge system – X1 + R1 + Z1, X2 + R2 + Z2

- Laser angle measurement system with live feedback to CNC control

- Quick release top tool clamping system

- Hydraulic top and bottom tool clamping system

- Additional back gauge fingers

- Additional front support arms

- CNC sheet follower support arms

- Parking area for sheet follower support arms – one per side