Morgan Rushworth PBSL Compact CNC Hydraulic Sheet Metal Press Brake

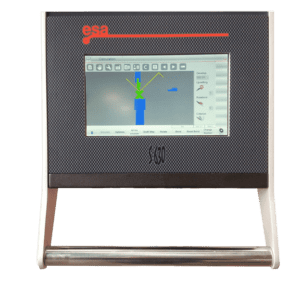

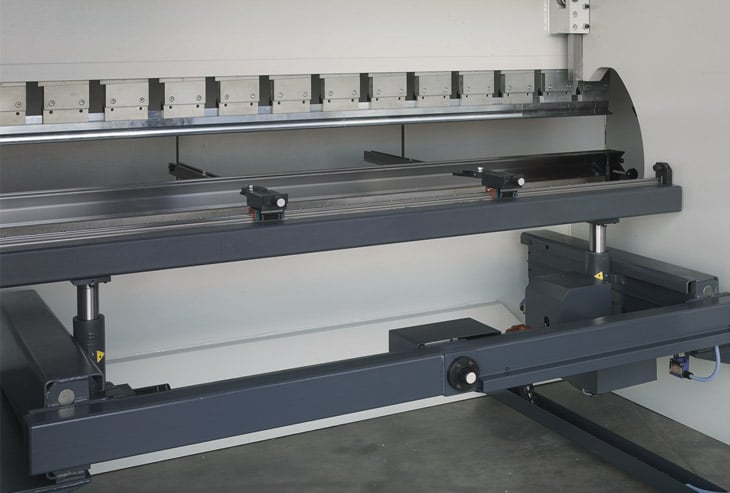

The Morgan Rushworth PBSL CNC press brakes are fitted with the ESA S 640 CNC control featuring a 15” touch screen and both numerical and 2D graphical program entry. Bending can also be graphically visualised in 2D showing the machine frame, top and bottom tools, back gauge fingers and part orientation. PC based software is included and, with the control networked, can be used to load programs from the office. The PBSL CNC models feature 3-axis CNC control of the left and right ram cylinders and the back gauge depth. The position of the two cylinders is fully synchronised with high precision scales on the side frames ensuring ram parallelism. AKAS laser tooling guards are standard and offer a vastly improved operator experience without compromising safety. All PBSL CNC models are supplied with sectionalised euro style top tools and a multi vee bottom die and can be specified with a number of options including crowning systems and CNC controlled R axis.

| BENDING POWER | BENDING LENGTH | DIST BETWEEN COLUMNS | Y RAPID SPEED | Y WORKING SPEED | Y RETURN SPEED | TRAVEL IN X AXIS | SPEED OF X AXIS | TRAVEL IN R AXIS (OPTIONAL) | SPEED OF R AXIS (OPTIONAL) | NO. OF BACKGUAGE FINGERS | NO. OF SHEET SUPPORT ARMS | OIL CAPACITY | MOTOR POWER | STROKE | DAYLIGHT | THROAT DEPTH | TABLE HEIGHT | TABLE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT | |

| MODEL | Tonne | A mm | B mm | mm/sec | mm/sec | mm/sec | mm | mm/sec | mm | mm/sec | Litre | kw | C mm | D mm | E mm | F mm | G mm | L mm | W mm | H mm | kg | ||

| PBSL CNC 3100/120 | 120 | 3,100 | 2,550 | 160 | 10 | 130 | 600 | 150 | 160 | 150 | 2 | 2 | 140 | 11 | 180 | 375 | 255 | 850 | 60 | 3,850 | 1,185 | 2,250 | 5,500 |

| PBSL CNC 3100/160 | 160 | 3,100 | 2,550 | 160 | 10 | 130 | 600 | 150 | 160 | 150 | 2 | 2 | 140 | 15 | 180 | 375 | 255 | 850 | 60 | 3,850 | 1,185 | 2,250 | 6,650 |

| PBSL CNC 3100/200 | 200 | 3,100 | 2,550 | 160 | 10 | 130 | 600 | 150 | 160 | 150 | 2 | 2 | 140 | 18.5 | 210 | 445 | 255 | 850 | 60 | 3,850 | 1,325 | 2,550 | 7,800 |

Features

- ESA S640 multi-axis CNC control with numerical and 2D graphical programming and visualisation, mounted on a pendant arm

- Fully synchronised CNC control of left and right upper beam cylinder position – Y1 + Y2 axis

- CNC control of back gauge depth – X axis

- Manual adjustment of back gauge height – R axis

- Manual side to side movement of back gauge fingers – Z axis

- Back gauge fingers with fine depth adjustment, adjustable laterally on a linear rail

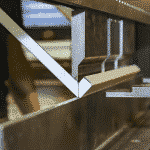

- Euro style top tool holders with wedge style intermediates

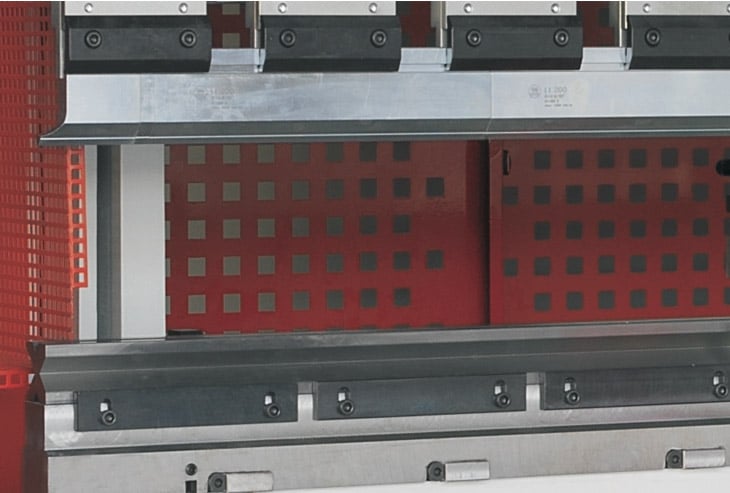

- Sectionalised goose neck top tool and multi vee bottom die

- AKAS laser tooling guards for enhanced ease of use

- High precision linear scales for measurement of the stroke depth

- Hydraulic ram travel guided in low friction slide ways

- High approach and return speeds for production bending

- Height adjustable front support arms

- Electrically interlocked side guards

Options

- CNC control of back gauge height – R axis

- Manual bottom tool crowning system with position counter

- CNC bottom tool crowning system

- Quick release top tool clamping system

- Additional back gauge fingers

- Additional front support arms