Morgan Rushworth PB NC Hydraulic Press Brake

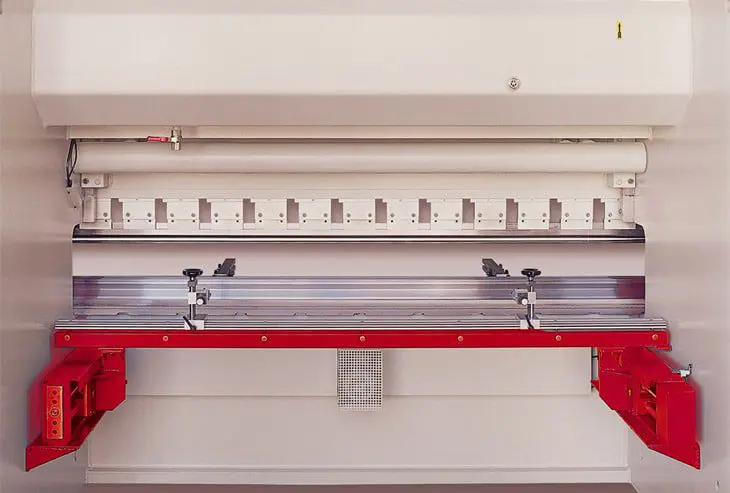

The conventional PB series press brake are manufactured with a heavy duty welded steel frame with strong torsion bar and hydro mechanical balancing system ensuring a long working life. PB machines range from 35 tonnes through to 300 tonnes with a bending length of up to 4100mm. All PB machines accept euro style tooling and are supplied with digital readouts for stroke control and for the power back gauge position. Side and rear guards with electrical interlocks are fitted as standard for increased safety.

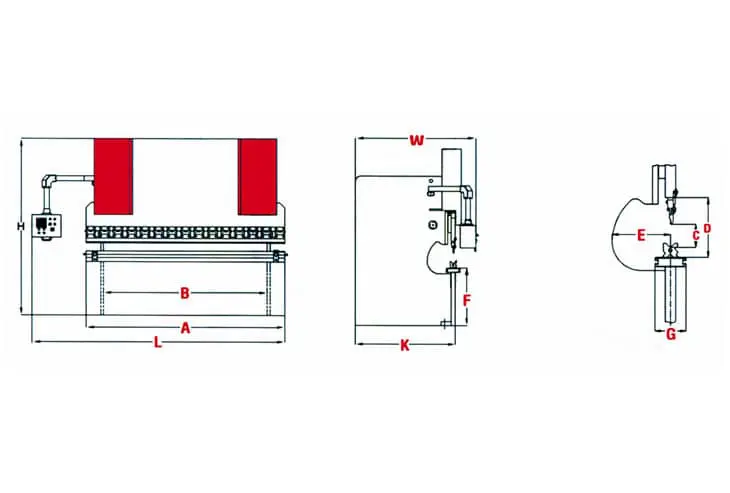

| MODEL | STOCK CODE | Bending Power |

Bending Length A mm |

Dist between columns B mm |

Y Rapid Speed mm/sec | Y Working Speed mm/sec | Y Return Speed

mm/sec |

Travel in X Axis mm | Oil Capacity lt | Motor Power kw | Stroke C mm | Daylight D mm | Throat Depth E mm | Table Height F mm | Table Width G mm | Length L mm | Height H mm | Width W mm | Weight kg |

| PB 1250/40 | M5000 | 35 | 1250 | 1070 | 100 | 10 | 70 | 750 | 80 | 4 | 150 | 470 | 410 | 800 | 140 | 2150 | 2150 | 1570 | 2200 |

| PB 2100/40 | M5001 | 40 | 2100 | 1600 | 90 | 10 | 70 | 750 | 80 | 4 | 80 | 410 | 310 | 800 | 140 | 3100 | 2150 | 1570 | 3000 |

| PB 2600/60 | M5002 | 60 | 2600 | 2050 | 90 | 9 | 65 | 750 | 100 | 5.5 | 110 | 450 | 310 | 860 | 140 | 3100 | 2150 | 1590 | 4800 |

| PB 2600/90 | M5003 | 90 | 2600 | 2050 | 80 | 10 | 80 | 750 | 130 | 7.5 | 120 | 475 | 310 | 860 | 170 | 3100 | 2270 | 1650 | 5650 |

| PB 3100/90 | M5004 | 90 | 3100 | 2550 | 95 | 10 | 80 | 750 | 170 | 7.5 | 120 | 460 | 310 | 870 | 140 | 4350 | 2270 | 1650 | 6500 |

| PB 3100/120 | M5005 | 120 | 3100 | 2550 | 100 | 10 | 90 | 750 | 170 | 11 | 130 | 485 | 310 | 870 | 170 | 4350 | 2370 | 2250 | 7950 |

| PB 3100/160 | M5006 | 160 | 3100 | 2550 | 90 | 8 | 75 | 750 | 180 | 11 | 140 | 510 | 310 | 870 | 200 | 4350 | 2450 | 2250 | 8700 |

| PB 3100/200 | M5007 | 200 | 3100 | 2550 | 100 | 8 | 75 | 750 | 210 | 15 | 150 | 525 | 310 | 880 | 240 | 4350 | 2520 | 2250 | 10500 |

| PB 3100/240 | M5008 | 240 | 3100 | 2550 | 70 | 8 | 55 | 750 | 210 | 18.5 | 160 | 580 | 310 | 880 | 280 | 4350 | 2650 | 2250 | 12000 |

| PB 3100/300 | M5009 | 300 | 3100 | 2550 | 80 | 9 | 60 | 750 | 240 | 22 | 180 | 595 | 380 | 900 | 380 | 4350 | 2850 | 2400 | 17000 |

| PB 3700/160 | M5010 | 160 | 3700 | 3250 | 90 | 8 | 75 | 750 | 210 | 11 | 140 | 500 | 310 | 870 | 170 | 4950 | 2450 | 1850 | 11200 |

| PB 3700/200 | M5011 | 200 | 3700 | 3250 | 100 | 8 | 75 | 750 | 210 | 15 | 150 | 540 | 310 | 880 | 240 | 4950 | 2520 | 2200 | 12500 |

| PB 3700/240 | M5012 | 240 | 3700 | 3250 | 70 | 8 | 55 | 750 | 260 | 18.5 | 160 | 565 | 310 | 880 | 240 | 4950 | 2650 | 2250 | 14000 |

| PB 4100/160 | M5013 | 160 | 4100 | 3550 | 90 | 8 | 75 | 750 | 260 | 11 | 140 | 500 | 310 | 880 | 170 | 5300 | 2450 | 1950 | 12500 |

| PB 4100/200 | M5014 | 200 | 4100 | 3550 | 100 | 8 | 75 | 750 | 260 | 15 | 150 | 510 | 310 | 880 | 200 | 5300 | 2520 | 2200 | 14500 |

| PB 4100/240 | M5015 | 240 | 4100 | 3550 | 100 | 8 | 55 | 750 | 260 | 18.5 | 160 | 565 | 310 | 880 | 240 | 5300 | 2650 | 2050 | 15000 |

| PB 4100/300 | M5016 | 300 | 4100 | 3550 | 80 | 9 | 60 | 750 | 300 | 22 | 180 | 595 | 380 | 900 | 280 | 5300 | 2850 | 2400 | 18500 |

Features

- European style top tool holders with wedge adjustment.

- Standard tooling: Goose-neck top tool and multi-vee bottom tool.

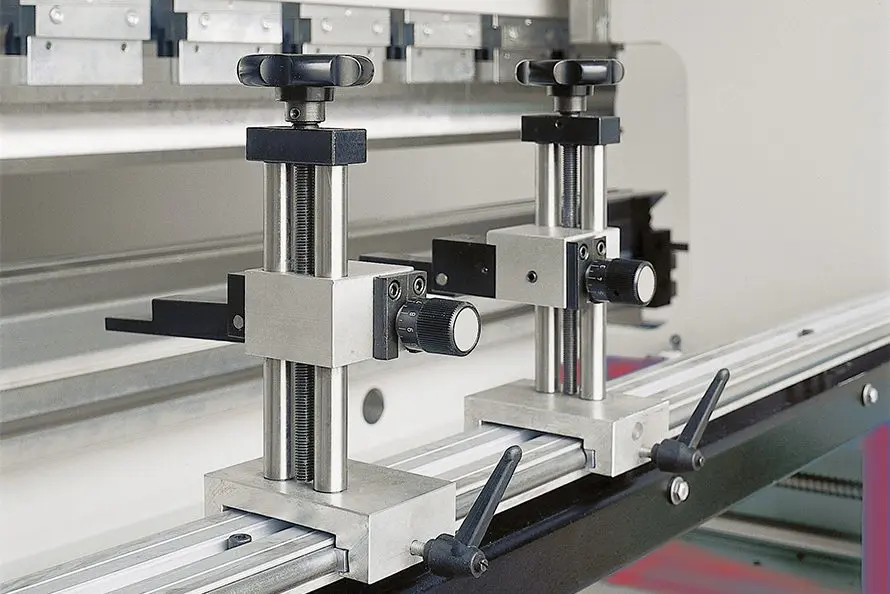

- Front operated, 750mm ballscrew back gauge with digital readout control (to 0.1mm precision) and two finger-stops with micro-adjustable height.

- Ram stroke control by precision mechanical-stops built into each cylinder and electrically adjusted by push-buttons with a digital position display.

- Independent position control of one cylinder-stop to provide fine angle adjustment and/or conical bending possibility.

- Pressure switch and gauge to regulate bending tonnage and to prevent over bending due to bottoming of tools.

- Pre-set, two-speed bending cycle giving fast approach, slow bending and fast return.

- 3-function foot-switch: normal bending, beam pause at any stroke point, automatic beam return upon release of foot-switch.

- Pendant control unit.

- Hand screw clamps and chains to align and secure bottom die.

- Two back gauge fingers.

- Two front support arms.

Options

- Programmable (NC) control for Y (stroke) and X (backgauge) axes.

- 1000mm backgauge length.

- Top tool quick release clamps.

- Anti deflection system.

- Additional backgauge fingers.

- Additional front support arm.

Morgan Rushworth PB NC Hydraulic Press Brake: Power, Precision, and Reliability

The Morgan Rushworth PB NC Hydraulic Press Brake is a trusted solution for those seeking robust performance and accuracy in metal bending applications. Designed with a focus on durability, safety, and efficiency, the PB series combines innovative engineering with practical features to meet the needs of modern workshops. Whether you’re working on intricate designs or handling large-scale production, this machine delivers consistent, high-quality results.

Built to Last: Heavy-Duty Steel Frame

At the core of the Morgan Rushworth PB series is its heavy-duty welded steel frame, engineered to withstand the toughest workloads. This solid construction ensures exceptional rigidity, reducing flex and vibrations during operation. The result? Superior bending accuracy and a press brake that will maintain its performance for years, even under the most demanding conditions.

Advanced Balancing for Precise Operations

The PB series press brake features a torsion bar and hydro-mechanical balancing system, which work together to maintain precision throughout the bending process. This advanced setup ensures that the ram movement is perfectly synchronised, delivering consistent bends across the entire working length. Operators can rely on this system for repeatable accuracy, no matter the material or complexity of the job.

Versatile Performance Range

With models ranging from 35 tonnes to 300 tonnes and bending lengths of up to 4100mm, the PB series offers a wide range of capabilities to suit various applications. From small-scale precision work to heavy-duty industrial tasks, this press brake is adaptable to the needs of diverse industries, including fabrication, automotive, and construction.

Seamless Integration with Euro-Style Tooling

The PB series is designed to work with Euro-style tooling, providing compatibility with a wide range of punches and dies. This flexibility allows operators to easily switch between different tools to accommodate various bending requirements. The standard configuration ensures that you can handle everything from basic operations to complex bends with ease and efficiency.

Digital Control for Enhanced Accuracy

To ensure precise operations, the PB press brake is equipped with digital readouts for stroke control and the power back gauge position. These intuitive controls allow operators to make precise adjustments, reducing the likelihood of errors and improving overall productivity. Whether fine-tuning the ram stroke or positioning the back gauge, the PB series makes it simple to achieve the desired results.

Safety First: Standard Guarding Features

The PB series places a strong emphasis on safety, with side and rear guards fitted as standard. These guards are equipped with electrical interlocks, ensuring that the machine meets strict safety standards while providing a secure working environment for operators. This focus on safety not only protects personnel but also minimises the risk of damage to the machine and tooling.

The Perfect Balance of Power and Precision

One of the standout features of the Morgan Rushworth PB NC Hydraulic Press Brake is its ability to balance raw power with unparalleled precision. Whether working with thin sheet metal or thick plates, this machine ensures clean, accurate bends every time. Its versatility and reliability make it an indispensable tool for manufacturers looking to achieve superior results across a variety of projects.

Applications Across Industries

The PB series press brakes are widely used in industries where precision and durability are paramount. Applications include:

- Metal Fabrication: From small custom parts to large structural components.

- Automotive Manufacturing: Creating body panels, brackets, and supports.

- Construction: Producing beams, frames, and reinforcing elements.

- General Engineering: Crafting components for machinery and equipment.

This versatility ensures that the PB series is a valuable asset for businesses across different sectors.

A Commitment to Innovation and Quality

Morgan Rushworth has a long-standing reputation for producing high-quality machinery, and the PB series is no exception. Every aspect of these press brakes is designed with the end user in mind, combining robust construction with cutting-edge technology. This commitment to innovation ensures that the PB series remains a top choice for businesses seeking reliable and efficient bending solutions.

Why Choose the Morgan Rushworth PB NC Hydraulic Press Brake?

The Morgan Rushworth PB NC Hydraulic Press Brake is more than just a machine; it’s an investment in quality, efficiency, and productivity. With its heavy-duty frame, precise control systems, and versatile tooling compatibility, it’s built to handle the challenges of modern manufacturing. Add in its emphasis on safety and ease of use, and it’s clear why the PB series is a trusted choice for workshops and factories worldwide.

When you choose the PB series, you’re not just investing in a press brake—you’re investing in a machine that will elevate your operations, ensuring consistent, high-quality results for years to come.