Delem DA-66T Controller

The new generation DA-Touch controls offer an ever higher grade of efficiency in programming, operation and control of today’s pressbrakes. Ease of use combined with state-of-the-art technology go hand in hand, improving productivity.

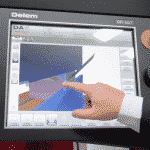

The touch screen screen gives access to the proven Delem user-interface and enables direct navigation between programming and production. Functions are directly located where you need them, offering optimised ergonomics throughout the application.

The DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimise the machine cycle and minimise set-up time. This makes using pressbrakes easier, more efficient and more versatile than ever. The OEM-panel located above the screen reserved for machine functions and OEM-application switches, is integrated in the design and can be used depending the required application.

General

- Real-time embedded Windows OS

- Multitasking environment

- Instant shut off

- Delem Modusys compatible

Electrical / Interfacing

- Power supply: 24V

- Modusys HSB bus

- RS232 port x2

- Network interface (100Mb/10Mb)

- USB port x2

- Safety PLC interfacing

- Protractor interfacing

- Angel control interfacing

Control

- Servo / 2 speed AC control

- Unipolair / frequency inverter control

- Direct pressure valve control

- Direct proportional valve Y1, Y2 control

- Direct crowning control

- Multiple digital function outputs

- Tandem operation

Programming

- Alphanumeric product naming

- 2D/3D real-scale product

- Programming and visualisation

- Automatic bend sequence calculation in 2D and 3D

- Easy graphical bend sequence swap and move

- Hemmed products programming table

- One page programming table

- Graphical product and tool selection

- Programmable material properties

- Programmable axis speed

- Free material programming

- Product & tool search filter

- Millimeters/inches, Kn/Ton selection

- Stock counter

- Product notes

Tooling

- Graphical tool configuration

- Multiple tool station set-ups

- Tool segmentation visualisation

- Alphanumeric tool identification

- Free graphical tool programming

- Hemming tools

- Radius tools

- Tool adapter support

Computed

- Tooling safety zones

- Press force

- Bend allowance

- Crowning adjustment

- Developed length

- Bottom force

- Hemming force

- Auto bumping calculation

- Radius programming

- Bend allowance table

- Learned angle correction database

Miscellaneous

- ‘Teach-in’ on all axes

- Handwheel movement of all axes

- Operator selectable dialogue languages

- Integrated help functions

- Error messaging system

- Diagnostic program

- Internet Explorer (web browser)

- Remote diagnosis

- User specific applications support

- Machine time + stroke counter

- On board Analysis Tool

- Sequencer functionality (PLC)

Features

- 3D and 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- 17″ high resolution colour TFT, high brightness

- Standard Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB flash memory drive

- Open system architecture

- Sensor bending and correction interface

- Colour LCD display

- 1280 x 1024 picels, 32 bit colour

- Full touch screen control (IR-touch)

- Storage capacity 1GB

- Emergency switch

- Integrated OEM-panel

Options

- Part support control

- X1-X2 angle programming

- Barcode reader interfacing

- Protractor interfacing

- Frame deflection compensation

- Sensor bending and correction interfacing

- Sheet thickness measurement and compensation system