Morgan Rushworth PBS CNC Hydraulic Sheet Metal Press Brake

The Morgan Rushworth PBS CNC range features the ESA 640 Touch Screen CNC controller, allowing offline PC programming. This streamlines multi-bend operations with complex forms, reducing errors and ensuring accuracy. The Y1 and Y2 axes are synchronised to 0.01mm with proportional valve technology.

Monoblock welded steel frames minimise deflection under load. Models range from 1250mm x 40T to 4100mm x 300T, with options like anti-deflection tables available to customise the machines to customer needs.

Standard Rear Backgauge Finger

X+R Axis Backgauge Fingers (Optional)

R-axis CNC (Optional)

Manual Anti Deflection Table (Optional )

Quick Release Tooling Clamps (Optional)

Laser Light Guard Protection

Sheet Support Arms

Sheet Follower Arms (Optional)

Manual Crowning (Optional)

CNC Crowning (Optional)

ESA 640 Controller

ESA 660 Touch Control Panel (Optional)

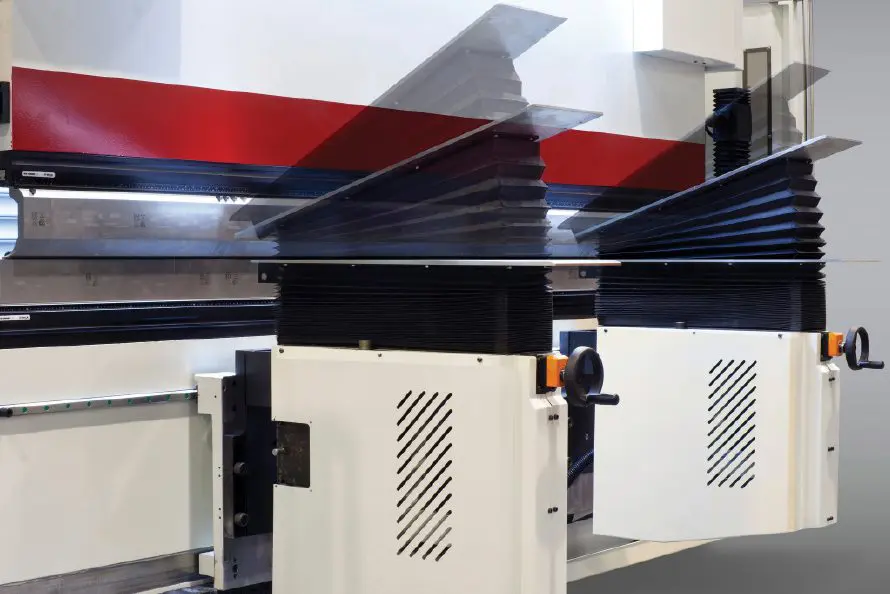

A recent installation of a Press Brake and Guillotine

| BENDING POWER | BENDING LENGTH | DIST BETWEEN COLUMNS | TRAVEL IN X AXIS | OIL CAPACITY | MOTOR POWER | STROKE | DAYLIGHT | THROAT DEPTH | TABLE HEIGHT | TABLE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT | ||

| MODEL | STOCK CODE | Tonne | A mm | B mm | mm | Litre | kw | C mm | D mm | E mm | F mm | G mm | L mm | W mm | H mm | kg |

| PBS CNC 1250/40 | M5042 | 40 | 1250 | 1070 | 1000 | 80 | 8 | 215 | 455 | 410 | 800 | 60 | 3000 | 2670 | 2250 | 3300 |

| PBS CNC 2100/60 | M5043 | 60 | 2100 | 1600 | 1000 | 140 | 9.5 | 210 | 475 | 410 | 880 | 60 | 3850 | 2780 | 2542 | 5400 |

| PBS CNC 2600/60 | M5044 | 60 | 2600 | 2050 | 1000 | 140 | 9.5 | 210 | 475 | 410 | 880 | 60 | 4350 | 2780 | 2542 | 6200 |

| PBS CNC 2600/90 | M5045 | 90 | 2600 | 2050 | 1000 | 140 | 11.5 | 260 | 530 | 410 | 890 | 60 | 4350 | 2780 | 2605 | 7100 |

| PBS CNC 3100/90 | M5046 | 90 | 3100 | 2550 | 1000 | 140 | 11.5 | 260 | 530 | 410 | 880 | 60 | 4850 | 2790 | 2605 | 7900 |

| PBS CNC 3100/120 | M5047 | 120 | 3100 | 2550 | 1000 | 140 | 15 | 260 | 530 | 410 | 890 | 60 | 4850 | 2790 | 2905 | 8400 |

| PBS CNC 3100/160 | M5048 | 160 | 3100 | 2550 | 1000 | 210 | 19 | 260 | 530 | 410 | 890 | 60 | 4850 | 2800 | 2905 | 9700 |

| PBS CNC 3100/200 | M5049 | 200 | 3100 | 2550 | 1000 | 210 | 22.5 | 260 | 530 | 410 | 880 | 60 | 4850 | 2800 | 2905 | 10000 |

| PBS CNC 3100/240 | M5050 | 240 | 3100 | 2550 | 1000 | 210 | 26 | 260 | 530 | 410 | 880 | 60 | 4850 | 2810 | 2905 | 11000 |

| PBS CNC 3100/300 | M5051 | 300 | 3100 | 2550 | 1000 | 280 | 26 | 320 | 660 | 500 | 905 | 280 | 4850 | 3015 | 3150 | 15000 |

| PBS CNC 3700/120 | M5052 | 120 | 3700 | 3250 | 1000 | 210 | 15 | 260 | 530 | 410 | 870 | 60 | 5450 | 2830 | 2905 | 11000 |

| PBS CNC 3700/160 | M5053 | 160 | 3700 | 3250 | 1000 | 210 | 19 | 260 | 530 | 410 | 880 | 60 | 5450 | 2800 | 2905 | 11500 |

| PBS CNC 3700/200 | M5054 | 200 | 3700 | 3250 | 1000 | 210 | 22.5 | 260 | 530 | 410 | 880 | 60 | 5450 | 2800 | 2905 | 12000 |

| PBS CNC 3700/240 | M5055 | 240 | 3700 | 3250 | 1000 | 210 | 26 | 260 | 530 | 410 | 880 | 60 | 5450 | 2810 | 2905 | 13500 |

| PBS CNC 3700/300 | M5056 | 300 | 3700 | 3250 | 1000 | 280 | 26 | 320 | 635 | 500 | 980 | 280 | 5450 | 3020 | 3200 | 17000 |

| PBS CNC 4100/160 | M5057 | 160 | 4100 | 3550 | 1000 | 210 | 19 | 260 | 530 | 410 | 880 | 60 | 5850 | 2800 | 2905 | 12000 |

| PBS CNC 4100/200 | M5058 | 200 | 4100 | 3550 | 1000 | 210 | 22.5 | 260 | 530 | 410 | 880 | 60 | 5850 | 2800 | 2905 | 12500 |

| PBS CNC 4100/240 | M5059 | 240 | 4100 | 3550 | 1000 | 210 | 26 | 260 | 530 | 410 | 880 | 60 | 5850 | 2810 | 2905 | 14000 |

| PBS CNC 4100/300 | M5060 | 300 | 4100 | 3550 | 1000 | 280 | 26 | 320 | 635 | 500 | 980 | 280 | 5850 | 3020 | 3200 | 18500 |

Features

- Strong rigid welded Monoblock frame able to withstand deflection under load.

- Sick CE front light guards

- User friendly ESA 640 Touch Screen CNC system with 2D auto bend sequence computations and large tool library.

- Full off line 2D graphical view programming software which can be transferred to the controller with USB flash disc.

- Ideal for multi bending of complex operations, especially where volume production with accurate repeatability is required.

- Bend accuracy at least five times higher than conventional press brakes.

- Fully synchronised Y1 and Y2 axis, accurate to 0.01mm with proportional valve technology.

- Hydraulic ram travel guided in low friction slideways.

- Fast CNC back gauge with AC servo drive.

- Euro style top clamps with intermediaries and quick release tool clamps.

- Sectionalised goose neck top tool.

- Sectionalised multi vee bottom die.

- High stroke and daylight opening.

- Deep throat design.

- Two front support arms on adjustable linear rail.

- Dual foot switch console with emergency stop.

- Swivelling pendant arm.

- Rear guard with photo cell safety beam.

- Ventilated electrical cabinet.

Options

- Manual anti deflection table

- CNC anti deflection table

- S540 2D colour graphical CNC controller

- Extra backgauge fingers