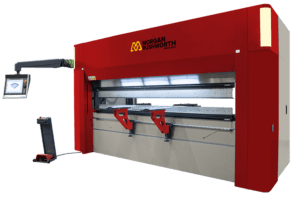

Morgan Rushworth mVision Interactive CNC Hydraulic Press Brake

The mVision Pressbrake offers a completely new level of connectivity between the machine and the operator.

Complex 3D products are unfolded in the machine software and projected on to the folding beam of the press brake, while life size tooling profiles appear above the actual tools ensuring the correct set up is achieved every time.

In a production cycle, both bend sequence and part orientation are graphically indicated in life size as well as aligned with the correct section of the tooling.

With an mVision Press Brake training time will be reduced, wastage will be reduced and a high level of efficiency and productivity will be achieved.

This product is now discontinued however we'd be happy to discuss alternative options with you. If you're looking for consumables, servicing or spare parts for this product, please contact our sales team.

VIEW AlTERNATIVES| MODEL | mVision CNC 3100/120 | mVision CNC 3100/160 | mVision CNC 3100/200 | mVision CNC 4100/160 | mVision CNC 4100/200 | mVision CNC 4100/240 | |

| Bending Power | Tonne | 120 | 160 | 200 | 160 | 200 | 240 |

| Bending Length | mm | 3100 | 3100 | 3100 | 4100 | 4100 | 4100 |

| Dist Between Columns | mm | 2550 | 2550 | 2550 | 3550 | 3550 | 3550 |

| Y Rapid Speed | mm/sec | 160 | 160 | 150 | 170 | 160 | 150 |

| Y Working Speed | mm/sec | 10 | 10 | 10 | 10 | 10 | 10 |

| Y Return Speed | mm/sec | 130 | 130 | 130 | 120 | 110 | 100 |

| Travel In X Axis | mm | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Speed Of X Axis | mm/sec | 330 | 330 | 330 | 330 | 330 | 330 |

| Travel In R Axis (Optional) | mm | 160 | 160 | 160 | 160 | 160 | 160 |

| Speed Of R Axis (Optional) | mm/sec | 240 | 240 | 240 | 240 | 240 | 240 |

| No of Backgauge Fingers | Amount | 2 | 2 | 2 | 2 | 2 | 2 |

| “Number Of Sheet Support Arms” | Amount | 2 | 2 | 2 | 2 | 2 | 2 |

| Oil Capacity | Li. | 140 | 210 | 210 | 210 | 210 | 210 |

| Motor Power | kw | 11 | 15 | 18.5 | 15 | 18.5 | 22 |

| Stroke | mm | 260 | 260 | 260 | 260 | 260 | 260 |

| Daylight | mm | 540 | 540 | 530 | 530 | 530 | 530 |

| Throat Depth | mm | 410 | 410 | 410 | 410 | 410 | 410 |

| Table Height | mm | 880 | 880 | 880 | 880 | 880 | 880 |

| Table Width | mm | 60 | 60 | 90 | 60 | 90 | 90 |

| Length | mm | 3850 | 3850 | 3850 | 4850 | 4850 | 4850 |

| Width | mm | 1590 | 1600 | 1600 | 1600 | 1600 | 1610 |

| Height | mm | 2905 | 2905 | 2905 | 2905 | 2905 | 2905 |

| Weight | kg | 8400 | 9700 | 10000 | 12000 | 12000 | 14000 |

Features

• mVision patented on-beam projection system

• CAL software for unfolding and sequencing of bends

• Full control of graphics with hand motion creating a simulated

touch screen on the folding beam

• Scroll through screens, enlarge part view and rotate view all on

the folding beam

• View tooling set up and correct tool profiles in life size against

actual tools

• Full graphical 3D simulation of bending process in real time

• Delem DA69T graphical touchscreen CNC control

• Full synchronisation of Y1 + Y2 axes to +/- 0.01mm accuracy

• High precision linear scales for measurement of stroke depth

•CNC-controlled X axis ballscrew backgauge with servo motors

• Steel mono-block construction

• High approach and return speeds for production bending

• 2 sliding front support arms with linear guide rails for lateral

adjustment

• AKAS laser tooling guards

• Independent Tower Type Backgauge X1 +R1 + Z1, X2 +R2 +Z2

• CNC Motorised Anti Deflection Crowning System

• Hydraulic Top and Bottom Tool Clamping (WILA Style)

Options

- Additional Sliding Front Arm

- Brush Table for Front Support Arm

- Parking Area on the side of the machine for Sliding Front Support Arms

- CNC Sheet Follower Support Arm

- Laser Angle Measuring System

- Pneumatic Top Tool Clamping (Euro Style)

- Pneumatic Bottom Tool Clamping (Euro Style)

The Benefits

- Highly visual display of bend sequence and component orientation greatly increases speed of operation

- Superior productivity as the next operation is immediately displayed without needing to refer to a separate

control - Operators do not require a high level of experience as intuitive control removes the need for specific

knowledge - Machine set up is simplified as tooling required for the current product is projected onto the beam in

life size.