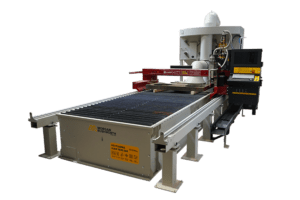

Morgan Rushworth ECP Compact CNC Plasma Cutting Machine

The Morgan Rushworth ECP Compact CNC Plasma cutting machines have been specifically designed for the simple yet accurate cutting of sheet and plate material. They are equipped with the operator-friendly LYNCA-CNC controller and are supplied with Libellula auto nesting software.

These heavy-duty models feature the class-leading Hypertherm Powermax power source, which utilizes single-gas plasma technology. The result is a high-quality machine that delivers low initial and operating costs, high productivity, superior cut quality, and unmatched reliability.

| MODEL | ECP 1530/45 | ECP 1530/65 | ECP 1530/85 | ECP 1530/105 | |

| STOCKCODE | 1530/45 | 1530/65 | 1530/85 | 1530/105 | |

| Capacity from Pierce | |||||

| Mild Steel | mm | 12 | 16 | 20 | 20 |

| Stainless | mm | 12 | 12 | 16 | 20 |

| Aluminium | mm | 10 | 12 | 16 | 20 |

| Capacity from Edge Start | |||||

| Mild Steel | mm | 20 | 25 | 30 | 40 |

| Stainless | mm | 20 | 20 | 25 | 32 |

| Aluminium | mm | 16 | 20 | 25 | 32 |

| Table Width | mm | 1500 | 1500 | 1500 | 1500 |

| Table Length | mm | 3000 | 3000 | 3000 | 3000 |

| X Axis Stroke | mm | 1550 | 1550 | 1550 | 1550 |

| Y Axis Stroke | mm | 3050 | 3050 | 3050 | 3050 |

| Z Axis Stroke | mm | 150 | 150 | 150 | 150 |

| Table Height | mm | 800 | 800 | 800 | 800 |

| Table Loading | kg/m² | 750 | 750 | 750 | 750 |

| Length | mm | 4420 | 4420 | 4420 | 4420 |

| Width | mm | 2350 | 2350 | 2350 | 2350 |

| Height | mm | 1710 | 1710 | 1710 | 1710 |

| Weight | kg | 2250 | 2250 | 2250 | 2250 |

Features

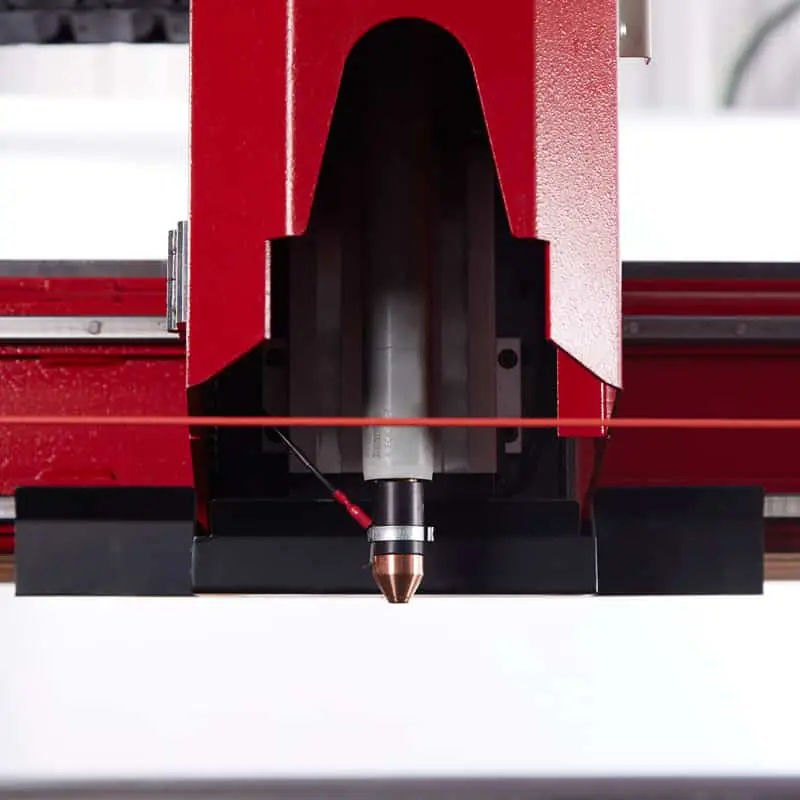

- Hypertherm Powermax 45/65/85/105 plasma unit for single gas cutting

- Air or Nitrogen cutting

- Easy to use touch screen LYNCA-CNC controller

- Automatic torch height control

- Torch collision protection system

- Automatic ventilation and smoke extraction system ready to be connected to a filtration system

- Positioning speed 15 m/min

- Positioning accuracy +/- 0.01mm

- LMT 25mm high accuracy linear rail

- High quality Eisele gearbox

- ESA AC digital servo motors and drivers

- Gudel helical rack and pinion system

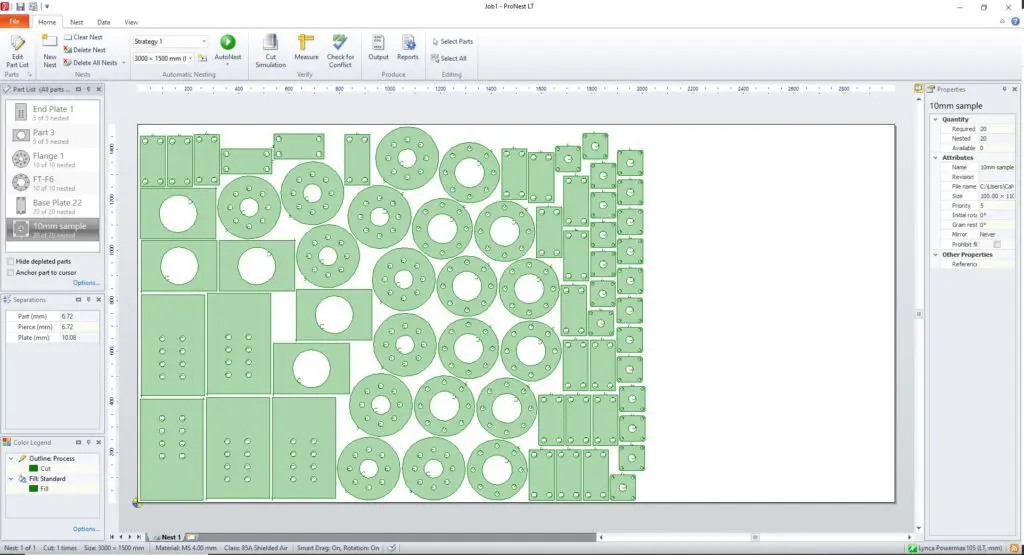

- Libellula auto nesting software

Options

- Water table in lieu of extraction table

- Extraction/filtration system

Morgan Rushworth ECP Compact CNC Plasma Cutting Machine

The Morgan Rushworth ECP Compact CNC Plasma Cutting Machines are specifically designed to provide simple yet precise cutting solutions for sheet and plate materials. With robust construction and user-friendly operation, these machines are ideal for businesses seeking efficient and cost-effective plasma cutting.

Advanced CNC Control and Software Integration

At the heart of the ECP Compact series is the intuitive LYNCA-CNC controller. This advanced yet straightforward system allows operators to manage cutting parameters with ease, streamlining the cutting process and reducing setup times. The machine is also supplied with Libellula auto nesting software, a powerful tool that optimises material usage by arranging parts in the most efficient way possible. This not only minimises waste but also maximises productivity.

Superior Cutting Technology

The ECP Compact machines are equipped with the Hypertherm Powermax power source, a class-leading component renowned for its performance and reliability. Utilising single-gas plasma technology, this system delivers clean and accurate cuts across a variety of materials. Operators can expect:

- Low operating costs: The efficient plasma system minimises gas and consumable usage.

- High productivity: Fast cutting speeds allow for quicker project turnaround times.

- Superior cut quality: Precise cuts reduce the need for secondary finishing processes.

- Unmatched reliability: Hypertherm’s proven technology ensures consistent performance over time.

Versatility in Material Handling

The Morgan Rushworth ECP Compact CNC Plasma Cutting Machine is designed to handle a wide range of materials, making it suitable for various industries, including fabrication, automotive, and construction. From thin sheet metal to thicker plate materials, the ECP Compact ensures accuracy and efficiency in every cut.

Robust Construction and Durability

Built to withstand the demands of a busy workshop, the ECP Compact features a heavy-duty frame that provides stability and precision during operation. This robust construction reduces vibration and enhances the quality of the cuts, ensuring consistent performance even under heavy use. The compact design also makes it a space-saving solution for workshops with limited floor space.

User-Friendly Features

The ECP Compact series prioritises ease of use, making it accessible to operators of all skill levels. Key features include:

- Touchscreen interface: Simplifies machine operation and parameter adjustments.

- Preloaded cutting programs: Speeds up setup times for common cutting tasks.

- Remote diagnostics: Enables quick troubleshooting and minimises downtime.

Energy Efficiency and Cost Savings

By incorporating the latest plasma cutting technology, the ECP Compact machines are designed to be energy-efficient, reducing overall power consumption. Additionally, the low operating costs make this machine a smart investment for businesses looking to improve their cutting capabilities while managing expenses.

Customisation Options

The Morgan Rushworth ECP Compact CNC Plasma Cutting Machine can be tailored to meet specific customer requirements. Optional features include:

- Upgraded power sources: For enhanced cutting capabilities.

- Additional safety features: To comply with stringent workplace regulations.

- Dust extraction systems: To maintain a clean and safe working environment.

Conclusion

The Morgan Rushworth ECP Compact CNC Plasma Cutting Machine represents the perfect combination of precision, efficiency, and affordability. With its advanced features and robust construction, it delivers exceptional performance for a wide range of cutting applications. Whether you’re a small workshop or a large-scale manufacturing facility, the ECP Compact is a reliable choice that will enhance your cutting operations and deliver significant cost savings.

Invest in the ECP Compact today and experience the benefits of superior plasma cutting technology.