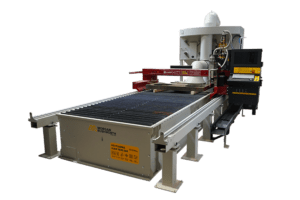

Ajan Oxy-Fuel CNC Grid Cutting Machine

The Ajan Oxy-Fuel CNC Grid Cutting Machine efficiently cuts various grating types used for platforms, flooring, racking, and stairways. It handles multiple thicknesses and offers high-quality profile cutting with excellent edge squareness and minimal dross.

Built to heavy industrial standards with in-house manufacturing, Ajan provides full support throughout the machine’s lifespan. Each model includes Ajan CAD/CAM software with free upgrades.

Optional features include extra oxy cutting torches and larger bed sizes.

| MODEL | 1.5m x 3m | 1.5m x 4m | 1.5m x 6m | |

| Cutting Capacity | mm | 40 | 40 | 40 |

| X Axis Stroke | mm | 1500 | 1500 | 1500 |

| Y Axis Stroke | mm | 3000 | 4000 | 6000 |

| Length | mm | 5900 | 7250 | 9100 |

| Width | mm | 3365 | 3865 | 3865 |

Features

- Specialist Grid Cutting Oxy Fuel Torch

- Automatic gas console

- Automatic torch height control

- Ajan CNC control unit using industry standard DIN/ISO ‘G’ codes

- Able to work with DXF, ESSI and NC toolpath files

- CAD drawing software

- CAM nesting and optimisation software

- Consistent quality, virtually dross free finish without the requirement for secondary operation

- X and Y axis precision rack and pinion system with AC servo motors

- Resume cutting feature

- Rapid traverse speed

- Fume extraction system beneath the table with exhaust connection at rear of machine that can be connected to factory extraction system or to optional filtration unit

- Additional Oxy fuel Cutting Torches can be added depending on your requirements

Options

- Additional Oxy fuel units

Ajan Oxy Fuel CNC Grid Cutting Machine

The Ajan Oxy Fuel CNC Grid Cutting Machine is the ultimate solution for efficient and precise cutting of various grating types, including full joint, press-locked, welded press fitting, and forge-welded grating. These gratings are commonly used for platforms, racking, flooring, and stairways, making the Ajan machine an indispensable tool for industries requiring high-quality grid cutting. Its ability to handle multiple material thicknesses ensures versatility and adaptability to diverse requirements.

Exceptional Cutting Capabilities

Ajan machines are renowned for their superior cutting performance. With the ability to process a wide range of materials, the machine delivers:

- High edge squareness: Ensuring precision cuts for a professional finish.

- Virtually dross-free results: Reducing the need for post-processing and improving efficiency.

- Consistent production feed rates: Maintaining high productivity even during prolonged operations.

These features make the Ajan Oxy Fuel CNC Grid Cutting Machine an ideal choice for businesses looking to enhance their production capabilities while achieving top-notch results.

Robust Industrial Construction

Built to withstand the rigours of heavy industrial use, Ajan machines feature:

- Heavy-duty construction: Providing stability and reliability during high-demand operations.

- In-house manufacturing: All components, including electronic parts, CNC units, cutting torches, servo motors, and steel structures, are produced in Ajan’s factories. This guarantees consistent quality and easy access to replacement parts.

- Long-lasting performance: The robust design ensures the machine’s durability, offering a dependable solution for long-term use.

This meticulous attention to quality and durability ensures that Ajan machines remain a reliable asset for any industrial setting.

Integrated Ajan CAD/CAM Software

Every Ajan Oxy Fuel CNC Grid Cutting Machine is equipped with Ajan CAD/CAM software, a comprehensive suite designed to enhance the user experience and optimise cutting efficiency. Key features include:

- Comprehensive design capabilities: Create and customise cutting profiles with ease.

- Free software upgrades: Ajan provides regular updates to ensure the software remains cutting-edge.

- User-friendly interface: Simplifies the design and nesting process, reducing operator training time.

The integration of Ajan CAD/CAM software streamlines operations and improves overall productivity, making it an essential component of the machine’s functionality.

Ajancam Nesting Software

Ajan’s proprietary AJANCAM automatic nesting and optimisation software is another highlight of the machine’s technological offerings. Designed to maximise material usage and minimise waste, AJANCAM provides:

- Efficient nesting capabilities: Optimises material layouts for minimal remnants.

- Ease of use: Simple to learn and practical to operate, even for novice users.

- Continuous improvement: New versions of AJANCAM are developed based on customer feedback, ensuring the software evolves to meet user needs.

This advanced nesting software significantly enhances productivity by enabling faster and more effective machining processes.

Multi-Tip Torches for Enhanced Cutting

The Ajan Oxy Fuel CNC Grid Cutting Machine features multi-tip cutting heads, a standout innovation that enhances its cutting efficiency. Key benefits include:

- Pre-heating capabilities: The multi-tipped head pre-heats the metal before the Oxy-Fuel head cuts through it, ensuring cleaner cuts.

- Integrated design: Combines pre-heating and cutting into a single head, reducing operational complexity.

- Fast and efficient grid cutting: Designed for assorted grid profiles, the multi-tip torches deliver precise results in minimal time.

This innovative feature streamlines the cutting process, making the machine ideal for high-volume production environments.

Customisable Options and Bed Sizes

To cater to diverse operational needs, the Ajan Oxy Fuel CNC Grid Cutting Machine offers a range of customisation options, including:

- Additional oxy cutting torches: Enhance productivity by enabling multiple cuts simultaneously.

- Larger bed sizes: Accommodate oversized materials for greater flexibility.

- Dust extraction systems: Maintain a clean and safe working environment by removing fumes and particulates.

These options allow businesses to tailor the machine to their specific requirements, ensuring maximum utility and efficiency.

Applications Across Industries

The versatility of the Ajan Oxy Fuel CNC Grid Cutting Machine makes it suitable for a wide range of applications, including:

- Construction: Cutting grating for platforms, flooring, and stairways.

- Manufacturing: Producing components for industrial racking and structural frameworks.

- Energy and utilities: Fabricating parts for power plants and oil refineries.

- Marine and offshore: Profiling grating for shipbuilding and offshore platforms.

This broad applicability highlights the machine’s value in various industrial sectors.

Unmatched Support and Reliability

Ajan’s commitment to quality extends to its customer support services. By manufacturing all machine components in-house, Ajan ensures:

- Quick access to replacement parts: Minimises downtime and keeps operations running smoothly.

- Comprehensive support: Ajan provides assistance throughout the machine’s working life, ensuring optimal performance.

- Reliable performance: Consistently high standards across all models.

This focus on support and reliability makes the Ajan Oxy Fuel CNC Grid Cutting Machine a trusted choice for businesses worldwide.

Conclusion

The Ajan Oxy Fuel CNC Grid Cutting Machine combines cutting-edge technology, robust construction, and user-friendly software to deliver exceptional performance. Its ability to handle diverse grating types, coupled with advanced features like AJANCAM nesting software and multi-tip torches, ensures precise and efficient cutting for a variety of industrial applications. With options for customisation and reliable support from Ajan, this machine is an invaluable investment for businesses seeking to enhance their grid cutting operations.

Choose the Ajan Oxy Fuel CNC Grid Cutting Machine for unparalleled precision, efficiency, and reliability in your cutting tasks.