Ajan High Definition Metal Cutting Plasma

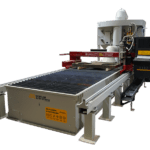

The Ajan High Definition CNC metal cutting plasma offer high quality profile cutting for a range of materials, delivering both excellent edge squareness and a virtually dross free finish, while maintaining production feed rates. The machines are constructed to a heavy industrial standard and, by manufacturing the machine totally in house including all of the electronic components, Ajan ensure that they can offer the required support to the machine for the duration of its working life.

All models come complete with Ajan CAD/CAM software including comprehensive features and free software upgrades. Options include the advanced bevel cutting plasma head, oxy cutting torches and a heavy industrial extraction/ filtration system, developed specifically for these models; alternatively they can be connected to a new or existing factory ducted system.

| MODEL | 1503/130 | 2004/130 | 2006/130 | 1503/260 | 2004/260 | 2006/260 | |

| Plasma Output | Amps | 30-130 | 30-130 | 30-130 | 30-260 | 30-260 | 30-260 |

| Production Pierce Capacity | |||||||

| Mild Steel | mm | 25 | 25 | 25 | 40 | 40 | 40 |

| Stainless Steel | mm | 20 | 20 | 20 | 25 | 25 | 25 |

| Aluminium | mm | 20 | 20 | 20 | 25 | 25 | 25 |

| Maximum Cutting Capacity | |||||||

| Mild Steel | mm | 30 | 30 | 30 | 65 | 65 | 65 |

| Stainless Steel | mm | 25 | 25 | 25 | 50 | 50 | 50 |

| Aluminium | mm | 25 | 25 | 25 | 50 | 50 | 50 |

| X Axis Stroke | mm | 1500 | 2000 | 2000 | 1500 | 2000 | 2000 |

| Y Axis Stroke | mm | 3000 | 4000 | 6000 | 3000 | 4000 | 6000 |

| Length | mm | 5900 | 7250 | 9100 | 5900 | 7250 | 9100 |

| Width | mm | 3365 | 3865 | 3865 | 3365 | 3865 | 3865 |

Features

- High Definition plasma cutting technology

- Automatic gas console

- Automatic torch height control

- Ajan CNC control unit using industry standard DIN/ISO ‘G’ codes

- Able to work with DXF, ESSI and NC toolpath files

- CAD drawing software

- CAM nesting and optimisation software

- Consistent quality, virtually dross free finish without the requirement for secondary operation

- ‘Optohole’ technology for bolt hole optimisation

- Strong steel frame designed to withstand constant high speed production

- X and Y axis precision rack and pinion system with AC servo motors

- Resume cutting feature

- Rapid traverse speed

- Marking and cutting of material performed with the same plasma torch

- Fume extraction system beneath the table with exhaust connection at rear of machine that can be connected to factory extraction system or to optional filtration unit

Options

- Oxy fuel units

- 4-axis bevel cutting head

- 5-axis bevel cutting head

- High efficiency extraction/filtration system

The Ajan high definition CNC plasma cutting machines offer high quality profile cutting for a range of materials, delivering both excellent edge squareness and a virtually dross free finish, while maintaining production feed rates. The machines are constructed to a heavy industrial standard and by manufacturing the machine totally in house including all of the electronic components. Ajan ensure that they can offer the required support to the machine for the duration of its working life. All models complete with Ajan CAD/CAM software including comprehensive features and free software upgrades. Options include the advanced bevel cutting plasma head, oxy cutting torches and a heavy industrial extraction/filtration system developed specifically for the these models; alternatively they can be connected to a new or existing factory ducted system.

“We can get bigger sheets on there, and as a result there are fewer offcuts, therefore reducing our costs. It is much faster and our clearing up time is much reduced compared to the old one – with the Ajan there is very little cleaning required. It has a bigger capacity, so we can fulfil more of our customer needs, do extra jobs above what we had the capability to do before.”

James Silk – J. Silk Agricultural Co. Ltd

Advantages

- Step by step nesting process with easy to use interface

- AJANCAD, AJANCAM and AJANPIPE all integrated in one software

- Compatible with all Window versions

- Broad language selection

- Easy and fast installation for unlimited number of computers

- Software guide and video tutorials are listed under the help menu

- Automatic update and ability to work with new integral functions

- Cutting bed sits flush to the floor, rather than raised up on stands, reduces vibrations

Machine Features

- High definition plasma cutting technology

- Consistent quality, virtually dross free finish

- Microjoint feature (preventing small parts from falling down by connecting them with the main plate through mini bridges)

- Optihole technology for bolt hole optimisation

- Automatic gas console

- Steel structure

- Dual side rack, pinion system AC Servo motor on X axis and Y axis

- Precision plasma 130/260 amp

- Standard marking on precision plasma

- Automatic torch height control

- Effective cutting without reducing the cutting speed for the vectors which have the same start and end angles. (High speed machining)

- The ability to go back to any position and resume cutting.

- The possibility to override all the parameters while the machine is working

- CAD drawing software

- CAM nesting and optimisation software

- 15m/min rapid traverse speed

- X axis can be increased on request

Ajan Electronics produces all machine parts in its own factories; the plasma generator, CNC unit, cutting torch, consumables, servo motors, moving parts, all electronic parts and steel structure which means we can source any replacement parts you might need quickly and easily, reducing downtime.

Torches

The Ajan can be fitted with a range of different torches, depending on what your cutting requirements are, using either the standard, straight cut touch, a bevel cutting torch, and an optional, interchangeable Oxy Fuel cutting Torch.

Straight Cut

- Standard straight cut torch

- Collision protection

- Economical, separate consumables for cost-effective and efficient cutting

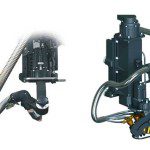

Bevel Cutting System

- Compact design

- The worlds lightest bevel head

- Full collision protection

- Bevelling range from 0 to 45°

- Maximum rotation angle 540°

- With one button press you can change the cutting from square to bevel

Oxy Fuel Torch

- Interchangeable head

- Multi head oxy fuel cutting possibility

- Automatic torch height control

- Automatic oxy fuel ignition

- Automatic or manual CNC gas control

- Quickly switching between Plasma and Oxy mode on the keyboard

Ajan Oxy-fuel cutting system with its CNC control unit provides an efficient cutting up to 200mm thickness of mild steel. An optional manual bevel cutting adapter is available.

“The value for money on the Ajan is phenomenal, we looked at various others with much higher price tags, but the quality straight off the Ajan is as good as, if not exceeding those other options we considered.”

Harry Hodgetts – A13 Engineering

Ajan Jet Filter Extraction System

The Ajan Jet Filter System are specially designed for heavy industry conditions. As a result of long lasting research and development work; with less air consumption and automatic filter cleaning property, the operation costs are reduced to minimum.

Features

- Efficient filtering more than 99%

- Filtering is done by applying pulse pressure

- High volume particles collecting bucket

- Flame resistant filters

- Self cleaning feature

- Low operation costs

Mechanical Air Suction System

The cutting smog is sucked out by a zoned mechanical air suction system, which is mounted on the cutting table. There is no extra cost for pneumatic suction mechanism.

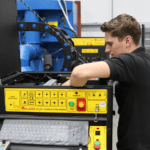

Ajan CNC Unit

Features

- P3 CPU

- Motherboard with P3 support

- 10/100 Mbps Ethernet Card

- USB Support

- 128 MB SD RAM PC133 Mhz

- 10 GB HDD

- 21” LCD Monitor

- PS/2 Mouse

Technical Specification

- All inclusive control panel (Dryer, ventilation, generator, jet filter)

- Free Ajan CAD program and Geometric Shapes Library

- Automatically cutting resume at break point after electricity shut down

- Working with standard ESSI, ISO, G codes. DXF files

- Leaves kerf width on the program to the cutting process

- Free software updates from the internet

- Language options as Turkish or English

- Automatically defining the sheet metal angle

- The CNC unit is made completely by Ajan, so we can secure any replacement parts as required, to get you up and running as quickly as possible.

Nesting and Optimisation Software

Ajan is a globally known brand in metal cutting and machining. In software fields Ajan provides effective solutions to the customers with the self-developed nesting software named AJANCAM. AJANCAM automatic nesting and optimisation software is easy to learn and practical to use.

AJANCAM increases productivity providing quick and effective machining with less remnants. New versions of AJANCAM will be developed and release in consideration of customer satisfaction and their feedback. With 40 years of experience all parts of CNC machines including generators, servo motors, torches and CNC Units are manufactured by AJAN. Moreover AJAN is the first company in this sector which developed its own Nesting Software Program.

CAD Nesting Software

- Sheet stock management module and control panel

- Common cut feature reduce the remnants and increase consumable life

- Parts connect feature: with one piercing action multiple parts cutting results in increased consumable life and ease of part collection process

- Sharper edges with loops specially

- Microjoint

- Automatically shape separation from single CAD drawing with multiple shapes

- Active UNDO/REDO feature in CAD and CAM modules

- The ability to save prepared nesting to use it at another time

- Partial automatic, partial manual nesting feature

- Ability to change the lead in – lead out lengths when edge cutting is applied

- Ability to add parts and sheets when needed

- Automatic and manual nesting features

- Interactive positioning: rotating, coping, mirroring, moving

- Automatic lead in – lead out values for all amperage and thickness and Line/Arc options for the lead in lead out

- Optional cutting strategies on the X-Y direction for the tool path optimisation

- Automatic and manual remnant cutting

CAD Design Module

- DXF and MPG files import ability

- Reduce nodes feature used with big complicated shapes

- Visual Error Detection and Fixing

- East TEXT feature with ability to extract letters from words

- Drawing and modifying commands

- Automatic marking

- Automatic open vector cutting

CNC Output-Reporting

- Automatic CNC mode

- Simulation of nesting cutting order

- PDF Report System: Nesting view, sheet size, material, cutting ampere, cutting order, weight part, total weight parts, part cutting time, weight sheet, total cutting time, cutting length nesting information, all necessary data for cost accounting.

- Cutting cost calculations

“We recently purchased the Ajan 260amp HD plasma with the interchangeable Oxy-fuel head and this product has been brilliant! The product is very easy to use and very efficient. We manufacture structural steel, this machine allows us to do all our profiling in house which helps up maximise profits and lead times. Very affordable machine all round with all running costs. The service we get from Selmach is brilliant and nothing is too much to ask. Brilliant Machine and service provided!”

Ryan Ridgewell – Ridgewell Steel