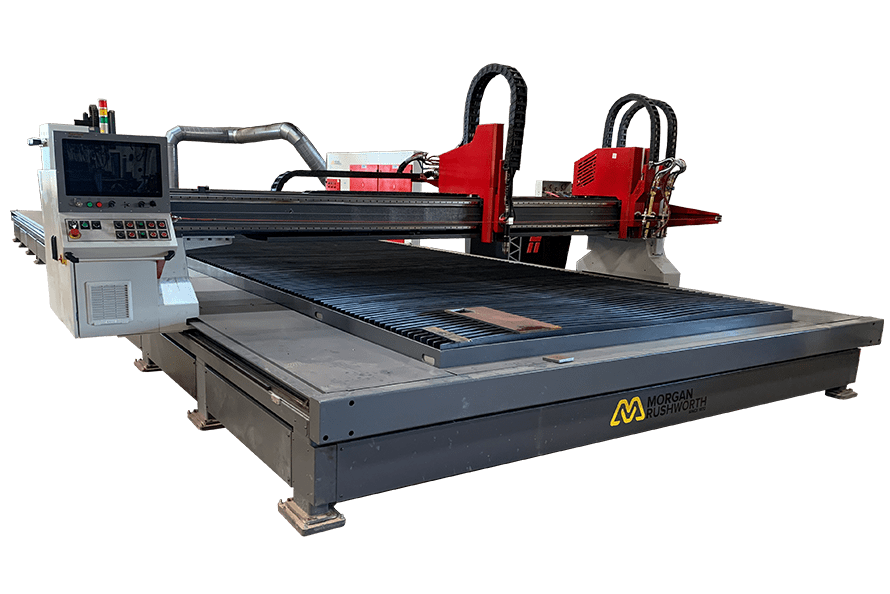

Morgan Rushworth HDPX Range of High Definition CNC Metal Cutting Plasma

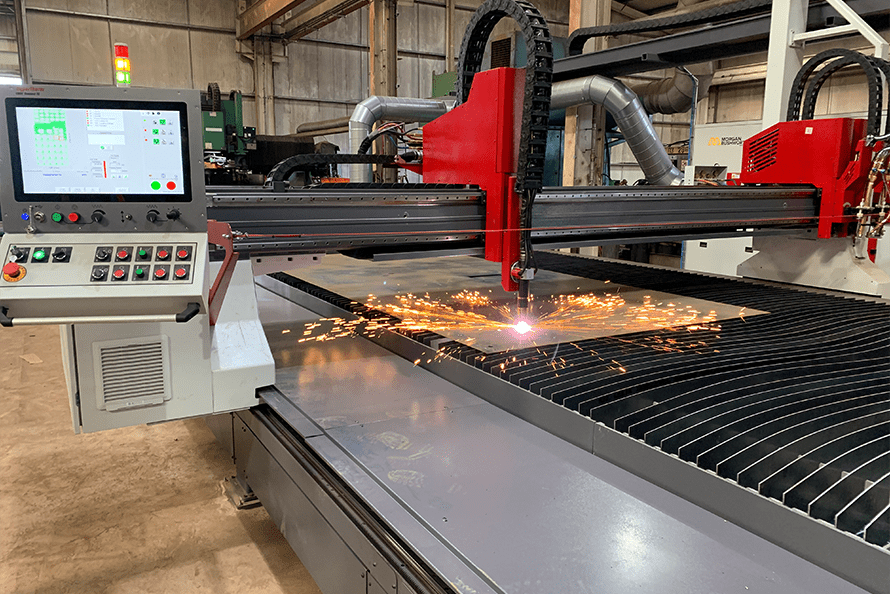

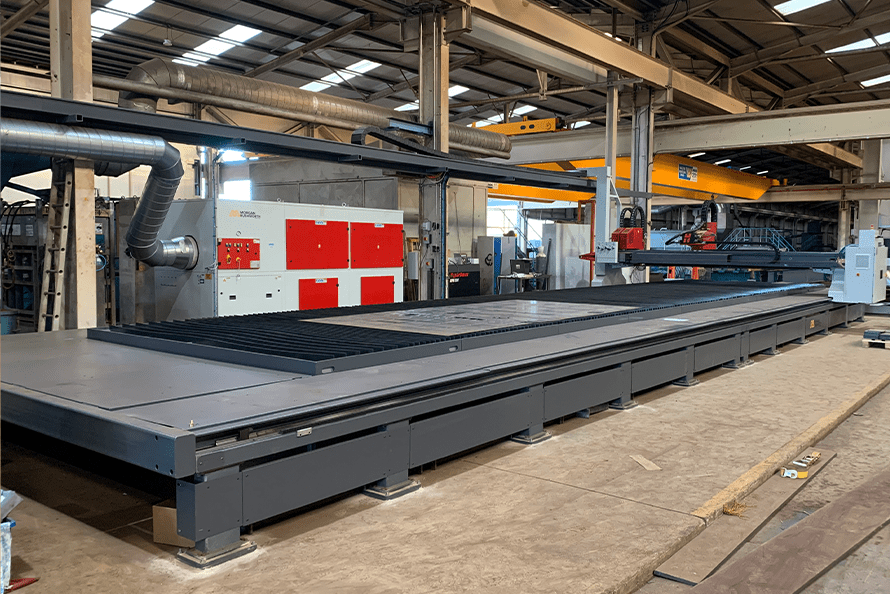

The HDPX High Definition CNC plasma machine is the flagship model from Morgan Rushworth and is offered in a huge range of bed sizes and with many optional features. The special bridge carrier design ensures precision cutting even on extremely long bed models and allows the fitting of optional equipment such as additional plasma torches for increased productivity and single or multiple oxy torch units for cutting up to 300mm thick material.

Hypertherm CNC Control

Hypertherm Cutting Head

Hypertherm XPR Plasma source

Hypertherm XPR Plasma source

| XPR 170 | XPR 300 | ||

| Plasma Output | Amps | 30 – 170 | 30 – 300 |

| Pierce Capacity | |||

| Mild Steel – Argon Assist | mm | 40 | 50 |

| Mild Steel – Standard | mm | 35 | 45 |

| Stainless Steel | mm | 22 | 38 |

| Aluminium | mm | 25 | 38 |

| Severance | |||

| Mild Steel | mm | 60 | 80 |

| Stainless Steel | mm | 38 | 75 |

| Aluminium | mm | 38 | 50 |

| MODEL | STOCK CODE | TABLE WIDTH | TABLE LENGTH | X AXIS STROKE | Y AXIS STROKE | HEIGHT UNDER TORCH | TABLE HEIGHT | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||

| HDPX 1503/170 | M8980 | 1700 | 3200 | 2300 | 3200 | 300 | 750 | 5200 | 3750 | 2200 | 4000 |

| HDPX 1503/170 | M8981 | 2200 | 4800 | 2800 | 4200 | 300 | 750 | 6200 | 4250 | 2200 | 6000 |

| HDPX 2006/170 | M8982 | 2200 | 6400 | 2800 | 6200 | 300 | 750 | 8200 | 4250 | 2200 | 8000 |

| HDPX 2504/170 | M8983 | 2700 | 4800 | 3300 | 4200 | 300 | 750 | 6200 | 4750 | 2200 | 7000 |

| HDPX 2506/170 | M8984 | 2700 | 6400 | 3300 | 6200 | 300 | 750 | 8200 | 4750 | 2200 | 9000 |

| HDPX 3006/170 | M8985 | 3200 | 6400 | 3800 | 6200 | 300 | 750 | 8200 | 5250 | 2200 | 10000 |

| HDPX 3009/170 | M8986 | 3200 | 9600 | 3800 | 9200 | 300 | 750 | 11200 | 5250 | 2200 | 12000 |

| HDPX 3012/170 | M8987 | 3200 | 12800 | 3800 | 12200 | 300 | 750 | 14200 | 5250 | 2200 | 15000 |

| HDPX 3014/170 | M8988 | 3200 | 14400 | 3800 | 14200 | 300 | 750 | 16200 | 5250 | 2200 | 17000 |

| HDPX 4006/170 | M8989 | 4200 | 6400 | 4800 | 6200 | 300 | 750 | 8200 | 6250 | 2200 | 12000 |

| HDPX 4009/170 | M8990 | 4200 | 9600 | 4800 | 9200 | 300 | 750 | 11200 | 6250 | 2200 | 14000 |

| HDPX 4012/170 | M8991 | 4200 | 12800 | 4800 | 12200 | 300 | 750 | 14200 | 6250 | 2200 | 17000 |

| HDPX 4014/170 | M89392 | 4200 | 14400 | 4800 | 14200 | 300 | 750 | 16200 | 6250 | 2200 | 19000 |

| HDPX 1503/300 | M8966 | 1700 | 3200 | 2300 | 3200 | 300 | 750 | 5200 | 3750 | 2200 | 4000 |

| HDPX 2004/300 | M8967 | 2200 | 4800 | 2800 | 4200 | 300 | 750 | 6200 | 4250 | 2200 | 6000 |

| HDPX 2006/300 | M8968 | 2200 | 6400 | 2800 | 6200 | 300 | 750 | 8200 | 4250 | 2200 | 8000 |

| HDPX 2504/300 | M8969 | 2700 | 4800 | 3300 | 4200 | 300 | 750 | 6200 | 4750 | 2200 | 7000 |

| HDPX 2506/300 | M8970 | 2700 | 6400 | 3300 | 6200 | 300 | 750 | 8200 | 4750 | 2200 | 9000 |

| HDPX 3006/300 | M8971 | 3200 | 6400 | 3800 | 6200 | 300 | 750 | 8200 | 5250 | 2200 | 10000 |

| HDPX 3009/300 | M8972 | 3200 | 9600 | 3800 | 9200 | 300 | 750 | 11200 | 5250 | 2200 | 12000 |

| HDPX 3012/300 | M8973 | 3200 | 12800 | 3800 | 12200 | 300 | 750 | 14200 | 5250 | 2200 | 15000 |

| HDPX 3014/300 | M8974 | 3200 | 14400 | 3800 | 14200 | 300 | 750 | 16200 | 5250 | 2200 | 17000 |

| HDPX 4006/300 | M8975 | 4200 | 6400 | 4800 | 6200 | 300 | 750 | 8200 | 6250 | 2200 | 12000 |

| HDPX 4009/300 | M8976 | 4200 | 9600 | 4800 | 9200 | 300 | 750 | 11200 | 6250 | 2200 | 14000 |

| HDPX 4012/300 | M8977 | 4200 | 12800 | 4800 | 12200 | 300 | 750 | 14200 | 6250 | 2200 | 17000 |

| HDPX 4014/300 | M8978 | 4200 | 14400 | 4800 | 14200 | 300 | 750 | 16200 | 6250 | 2200 | 19000 |

The Table Size can range from 1500 x 3000mm – 6000 x 36000mm depending on your requirements.

Features

- Hypertherm XPR High Definition Plasma with X Definition Technology

- Hypertherm Core gas console

- Hypertherm torch height control and cutting torch

- Hypertherm Windows based EDGE Connect CNC control and ProNest software

- Virtually dross free finish typically removing the requirement for a secondary cleaning operation

- Maximised productivity and minimised operating costs

- Extremely heavy steel frame designed to withstand constant high speed production

- Bridge carrier design highly resistant to distortion suitable for multi plasma heads and oxy fuel cutting heads and allowing for precision positioning on bed lengths of up to 60 metres

- X and Y axis travel on precision linear guide rails with synchronised servo drives

- Fast positioning speed of 30 m/min with positioning accuracy to 0.05mm

- Arc voltage feedback to control optimum torch height position

- Mechanical and electronic collision avoidance system

- Marking and cutting of material performed with the same plasma torch

Options

- Single station drilling head (requires EDGE Pro control)

- Three station drilling head (requires EDGE Pro control)

- Additional plasma systems (maximum 4 units)

- Six station drilling head (requires EDGE Pro control)

- Bevel cutting plasma head (increases bed width by 500mm. Requires EDGE Pro control)

- CNC tube plasma attachment (requires EDGE Pro control)

- Upgrade to Hypertherm EDGE Pro CNC control

- High efficiency extraction/filtration unit

- Auto nesting software