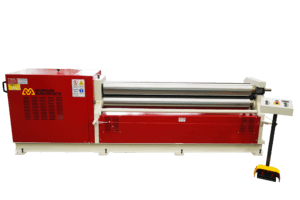

Morgan Rushworth DPBH-3 Hydraulic Bending Roll

The Morgan Rushworth DPBH-3 hydraulic bending rolls are of the pyramid style with all three rolls hydraulically driven. The models with roll diameters up to 300mm are fitted with the type A shaft design with orbital action for up and down transition. The machines with roll diameters from 320mm to 550mm are equipped with the type B shaft design with linear action for up and down translation. All models have hydraulic drop end and supplied with DRO to indicate roll position.

| MODEL | STOCK CODE | BENDING LENGTH | PRE BENDING | MAX THICKNESS | TOP ROLL dia | BOTTOM ROLLS dia | MOTOR | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | mm | mm | kw | mm | mm | mm | kg | ||

| DPBH-3 2050/210 | M3500 | 2050 | 10 | 12 | 210 | 190 | 7.5 | 3400 | 1200 | 1300 | 4100 |

| DPBH-3 2050/240 | M3501 | 2050 | 13 | 15 | 240 | 220 | 7.5 | 3400 | 1300 | 1450 | 495 |

| DPBH-3 2050/280 | M3502 | 2050 | 16 | 18 | 280 | 260 | 7.5 | 4100 | 1400 | 1550 | 6850 |

| DPBH-3 2050/300 | M3503 | 2050 | 20 | 22 | 300 | 280 | 11 | 4100 | 1500 | 1550 | 7400 |

| DPBH-3 2050/320 | M3504 | 2050 | 20 | 25 | 320 | 310 | 22 | 4600 | 1750 | 1950 | 10450 |

| DPBH-3 2050/350 | M3505 | 2050 | 25 | 30 | 350 | 330 | 22 | 4600 | 1750 | 2000 | 10980 |

| DPBH-3 2550/210 | M3511 | 2550 | 8 | 10 | 210 | 190 | 7.5 | 3900 | 1200 | 1300 | 4570 |

| DPBH-3 2550/240 | M3512 | 2550 | 10 | 12 | 240 | 220 | 7.5 | 3900 | 1300 | 1450 | 5600 |

| DPBH-3 2550/280 | M3513 | 2550 | 13 | 15 | 280 | 260 | 7.5 | 4600 | 1400 | 1550 | 7720 |

| DPBH-3 2550/300 | M3514 | 2550 | 16 | 18 | 300 | 280 | 11 | 4600 | 1500 | 1550 | 8400 |

| DPBH-3 2550/320 | M3515 | 2550 | 16 | 20 | 320 | 310 | 22 | 5100 | 1750 | 1950 | 11450 |

| DPBH-3 2550/350 | M3516 | 2550 | 20 | 25 | 350 | 330 | 22 | 5100 | 1750 | 2000 | 12030 |

| DPBH-3 3100/210 | M3522 | 3100 | 6 | 7 | 210 | 190 | 7.5 | 4450 | 1200 | 1300 | 5205 |

| DPBH-3 3100/240 | M3523 | 3100 | 8 | 10 | 240 | 220 | 7.5 | 4450 | 1300 | 1450 | 6600 |

| DPBH-3 3100/280 | M3524 | 3100 | 10 | 12 | 280 | 260 | 7.5 | 5150 | 1400 | 1550 | 8370 |

| DPBH-3 3100/300 | M3525 | 3100 | 13 | 15 | 300 | 280 | 11 | 5150 | 1500 | 1550 | 9050 |

| DPBH-3 3100/320 | M3526 | 3100 | 13 | 16 | 320 | 310 | 22 | 5600 | 1750 | 1950 | 13450 |

| DPBH-3 3100/350 | M3527 | 3100 | 16 | 20 | 350 | 330 | 22 | 5600 | 1750 | 2000 | 14260 |

Features

- Hydraulic driven rolls

- Hydraulic drop end and top roll tilt

- Hydraulic up and down roll movement

- Induction hardened rolls

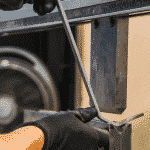

- Double pre bending to the front and rear edge of plate

- Cone bending device

- Welded steel construction

- Safety trip wire around the machine

- Mobile control panel

Options

- Side and central supports for large sheet metal diameters

- Extended rolls

- Profile rolls

- Material feed table