Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls

The DPBR-4 hydraulic bending rolls are available with roll diameters from 150mm to 260mm. They feature a 4-roll design with powered top and bottom rolls and hydraulically adjusted side rolls. This setup assists operators, especially for rolling cylinders and multiple radius bends, as the workpiece is securely pinched between the top and bottom rolls. Pre-bending can be performed on both side rolls without removing the workpiece.

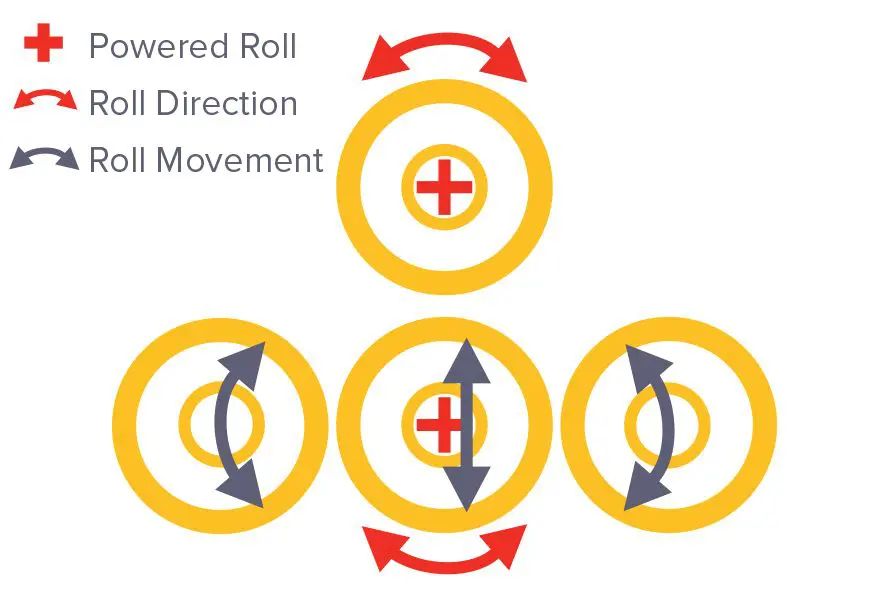

All models include a hydraulic drop end for quick removal of components and digital readouts to indicate roll position. The DPBR-4 range uses orbital rolling action for precise, consistent performance.

| MODEL | STOCK CODE | BENDING LENGTH | PRE BENDING | MAX THICKNESS | TOP/BOTTOM ROLL dia | SIDE ROLLS dia | MOTOR | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | mm | mm | kw | mm | mm | mm | kg | ||

| DPBR-4 1550/150 | M3580 | 1550 | 4.5 | 7 | 150 | 130 | 4 | 3750 | 960 | 1100 | 2500 |

| DPBR4 1550/180 | M3801 | 1550 | 7 | 9 | 180 | 150 | 5.5 | 3900 | 1100 | 1250 | 3250 |

| DPBR-4 1550/200 | M3802 | 1550 | 9 | 11 | 200 | 160 | 5.5 | 3900 | 1100 | 1250 | 3500 |

| DPBR-4 1550/220 | M3803 | 1550 | 10 | 12 | 240 | 160 | 5.5 | 3900 | 1100 | 1250 | 3600 |

| DPBR-4 1550/245 | M3804 | 1550 | 15 | 12 | 245 | 180 | 7.5 | 3800 | 1425 | 1470 | 4600 |

| DPBR-4 2050/150 | M3582 | 2050 | 4 | 6 | 150 | 130 | 4 | 4250 | 960 | 1100 | 2800 |

| DPBR-4 2050/180 | M3806 | 2050 | 6 | 8 | 180 | 150 | 5.5 | 4400 | 1100 | 1250 | 3500 |

| DPBR-4 2050/200 | M3808 | 2050 | 8 | 10 | 200 | 160 | 5.5 | 4400 | 1100 | 1250 | 3950 |

| DPBR-4 2050/220 | M3585 | 2050 | 9 | 11 | 220 | 160 | 5.5 | 4400 | 1100 | 1250 | 4050 |

| DPBR-4 2050/245 | M3586 | 2050 | 10 | 13 | 245 | 180 | 7.5 | 4300 | 1425 | 1470 | 5450 |

| DPBR-4 2050/260 | M3587 | 2050 | 13 | 16 | 260 | 200 | 7.5 | 4300 | 1460 | 1550 | 6100 |

| DPBR-4 2550/180 | M3813 | 2550 | 4 | 6 | 180 | 150 | 5.5 | 4900 | 1100 | 1250 | 3900 |

| DPBR-4 2550/200 | M3814 | 2550 | 6 | 8 | 200 | 160 | 5.5 | 4900 | 1100 | 1250 | 4550 |

| DPBR-4 2550/220 | M3589 | 2550 | 7 | 9 | 220 | 160 | 5.5 | 4900 | 1100 | 1250 | 4600 |

| DPBR-4 2500/245 | M3590 | 2550 | 8 | 10 | 245 | 180 | 7.5 | 4800 | 1425 | 1470 | 5700 |

| DPBR-4 2500/260 | M3591 | 2550 | 10 | 13 | 260 | 200 | 7.5 | 4800 | 1460 | 1550 | 6800 |

| DPBR-4 3100/180 | M3816 | 3100 | 3 | 5 | 180 | 150 | 5.5 | 5450 | 1100 | 1250 | 4300 |

| DPBR-4 3100/200 | M3817 | 3100 | 4 | 6 | 200 | 160 | 5.5 | 5450 | 1100 | 1250 | 4900 |

| DPBR-4 3100/220 | M3593 | 3100 | 6 | 8 | 220 | 160 | 5.5 | 5450 | 1100 | 1250 | 5200 |

| DPBR-4 3100/245 | M3594 | 3100 | 7 | 9 | 245 | 160 | 7.5 | 5350 | 1425 | 1470 | 6350 |

| DPBR-4 3100/260 | M3595 | 3100 | 8 | 10 | 260 | 180 | 7.5 | 5350 | 1460 | 1550 | 7500 |

| DPBR-4 4100/260 | M3596 | 4100 | 4 | 6 | 260 | 200 | 7.5 | 6350 | 1460 | 1550 | 8900 |

Capacities are given for 250 N/mm² plate yielding strength

Features

- Powered top and bottom rolls with hydro motor and cardan joint

- Hydraulic drop end

- Hydraulic up and down roll movement

- Hydraulic pinching

- Induction hardened rolls

- Digital read out for both side rollers and pinch roll

- Double pre bending to front and rear edge of plate

- Cone bending device

- Welded steel construction

- Safety trip wire around the machine

- Mobile control panel

- Two rolling speeds

- Central lubrication system

Options

- Side and central sheet supports

- Ground and polished rolls

- Variable speed

- NC controller or CNC controller

Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls

The Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls are robust and precision-engineered machines designed to handle a variety of demanding sheet metal and plate bending tasks. Available with roll diameters ranging from 150mm to 260mm, these machines provide versatility and reliability for workshops and industrial fabrication facilities. The 4-roll design offers significant advantages over traditional bending rolls, making them ideal for rolling full cylinders and creating multiple-radius bends with exceptional accuracy and efficiency.

A key feature of the DPBR-4 range is the powered top and bottom pinch rolls, which work in tandem with hydraulically adjusted side rolls. This configuration ensures that the workpiece remains securely pinched between the top and bottom rolls throughout the bending process. By maintaining consistent control over the material, the DPBR-4 machines enable operators to achieve smooth, precise bends while minimising errors and material slippage. This makes them an excellent choice for industries where precision and repeatability are essential.

Advanced 4-Roll Design

The 4-roll design of the Morgan Rushworth DPBR-4 Hydraulic Plate Bending Rolls offers numerous benefits for both experienced operators and those new to plate bending. One of the standout features of this design is its ability to perform pre-bending on both side rolls without requiring the workpiece to be removed from the machine. This capability streamlines the workflow and reduces downtime, as operators can complete pre-bending and rolling in a single setup.

Additionally, the 4-roll configuration makes these machines particularly well-suited for rolling full cylinders. The constant pinching action provided by the top and bottom rolls ensures that the material is held firmly in place, resulting in consistent, high-quality bends. This feature is especially valuable when working with thicker plates or when producing large-diameter cylinders, as it simplifies the process and improves accuracy.

Orbital Rolling Action for Enhanced Precision

One of the key innovations of the DPBR-4 range is its use of orbital rolling action, rather than linear motion. This advanced rolling mechanism enhances the machine’s precision by providing smoother and more controlled movements during the bending process. Orbital rolling action also reduces stress on the material, resulting in a more uniform finish and improved overall quality.

This feature makes the DPBR-4 machines an excellent choice for projects requiring high levels of accuracy, such as those in the aerospace, automotive, and construction industries. Whether producing structural components, industrial equipment, or decorative metalwork, the orbital rolling action ensures consistent, professional-grade results.

Hydraulic Drop End and Digital Readouts

The Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls are equipped with a hydraulic drop end, which facilitates the quick and easy removal of rolled components. This feature streamlines the workflow and enhances operator efficiency, particularly when working with large or heavy workpieces. By simplifying the ejection process, the hydraulic drop end reduces downtime and increases productivity, making these machines ideal for high-volume production environments.

All models in the DPBR-4 range come with digital readouts for all three adjustable rolls. These readouts provide real-time feedback on the roll positions, enabling operators to make precise adjustments and maintain consistent control over the bending process. The digital readouts improve accuracy and simplify the setup process, ensuring that operators can achieve the desired results quickly and efficiently.

Applications Across Industries

The Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls are versatile machines suitable for a wide range of applications across multiple industries. Common uses include:

- Aerospace Engineering: Producing precision components such as fuselage sections and structural supports.

- Automotive Manufacturing: Rolling chassis components, reinforcements, and other critical parts.

- Construction: Bending structural steel for beams, columns, and other architectural elements.

- Industrial Equipment: Forming cylindrical or conical shapes for machinery and equipment.

- HVAC Systems: Rolling ducts, pipes, and ventilation components.

The DPBR-4 range’s ability to handle diverse materials and complex projects makes it a valuable addition to workshops and fabrication facilities of all sizes.

Ease of Use and Operator Efficiency

Despite their advanced capabilities, the DPBR-4 machines are designed with ease of use in mind. The hydraulic controls are intuitive and responsive, allowing operators to make precise adjustments with minimal effort. The digital readouts simplify the operation further by providing clear and accurate information on roll positions, enabling operators to focus on achieving high-quality results.

The 4-roll design and hydraulic features also reduce operator fatigue by streamlining the bending process and minimising the need for manual intervention. These user-friendly features make the DPBR-4 range an excellent choice for workshops seeking to improve productivity and maintain consistent quality across a wide range of applications.

Why Choose the DPBR-4 Range?

The Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls stand out for their combination of precision, durability, and advanced functionality. With features such as powered top and bottom pinch rolls, hydraulically adjusted side rolls, orbital rolling action, and digital readouts, these machines offer a comprehensive solution for plate bending tasks of all complexities.

Their robust construction and innovative design ensure long-term reliability and consistent performance, making them a cost-effective investment for businesses looking to enhance their bending capabilities. Whether working on small-scale projects or large industrial tasks, the DPBR-4 range delivers the precision and efficiency required to meet the demands of modern fabrication.

Conclusion

The Morgan Rushworth DPBR-4 Hydraulic 4 Roll Plate Bending Rolls are a versatile and high-performance solution for a wide range of bending applications. Their advanced 4-roll design, orbital rolling action, and user-friendly features make them an excellent choice for workshops and industrial facilities seeking reliable and efficient plate bending equipment.

With their ability to handle diverse materials, ensure precision, and streamline workflows, the DPBR-4 machines represent the perfect balance of innovation and practicality. Backed by Morgan Rushworth’s reputation for quality and engineering excellence, these machines are an investment that guarantees exceptional results for years to come.