Morgan Rushworth DPR Powered Sheet Metal Bending Rolls

The Morgan Rushworth DPR Powered Bending Sheet Roll range from 0.6mm – 0.8mm with bending lengths up to 1050mm. All models are of asymmetric design providing pre bending capability. The top slip roll allows removal of cylindrical components.

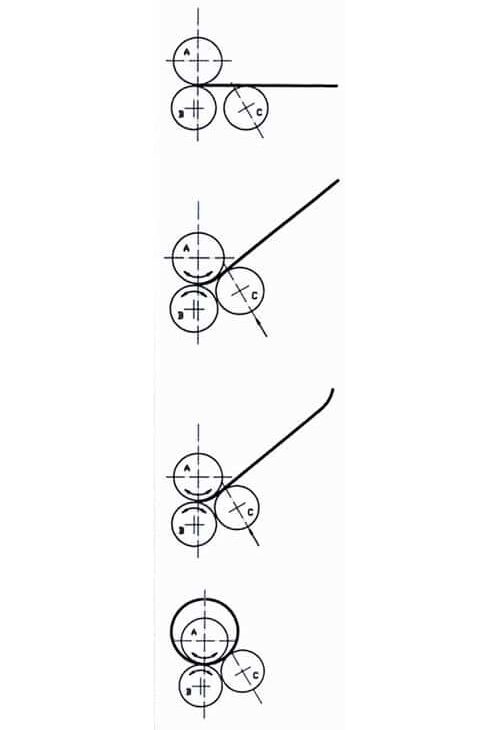

Asymmetrical Rolls

Top Slip Rolls

Top Roll to Slip

Manual Pinching of Bottom Roll

Heavy Duty Motor

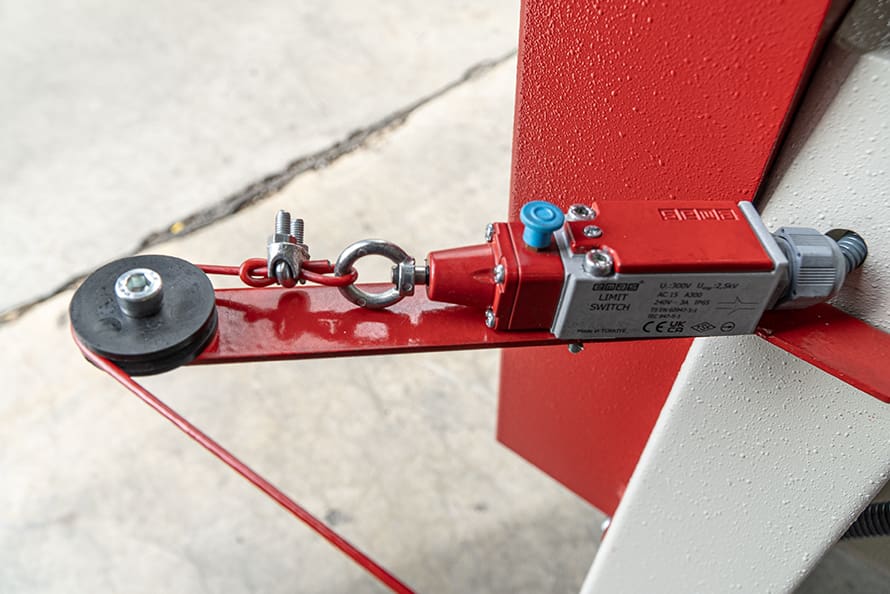

Trip Wire Mechanism

Foot Pedal Control

| MODEL | STOCK CODE | BENDING LENGTH | PRE BENDING | MAX THICKNESS | TOP ROLL DIA | LENGTH | HEIGHT | WIDTH | WEIGHT |

| mm | mm | mm | mm | mm | mm | mm | kg | ||

| DPR 1050/46 | M3609 | 1050 | 0.6 | 0.8 | 46 | 1500 | 1120 | 700 | 210 |

| DPR 1050/56 | M3610 | 1050 | 0.8 | 1 | 56 | 1500 | 1120 | 700 | 240 |

Capacities are given for 250 N/mm² plate yielding strength

Features

- Top roll to slip

- Powered rotation

- Crowned Rolls

- Manually adjusted side roll for up and down translation

- Manual pinching of bottom roll

Options

- Induction hardened rolls

- Parallel Rolls

- Powered side roll up and down translation

- DRO for side roll position