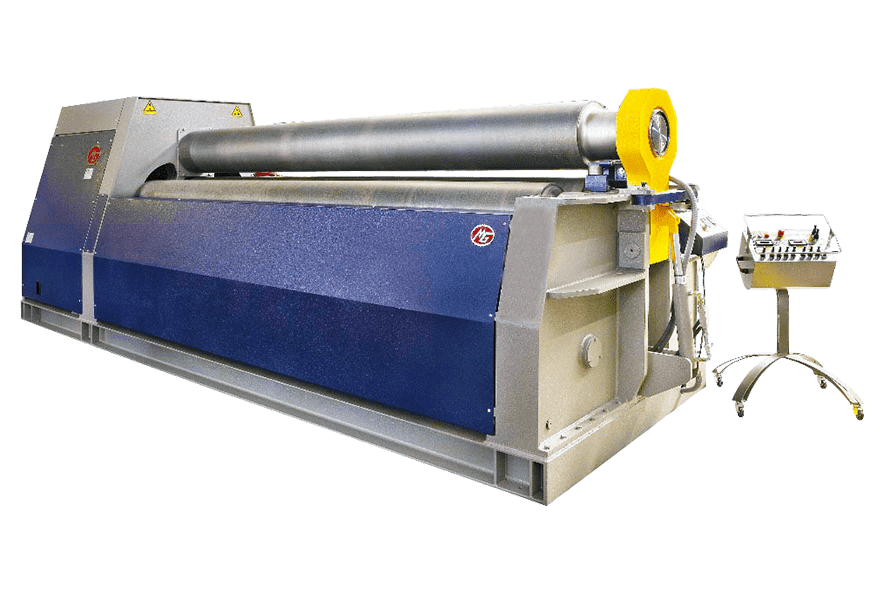

MG M Series Hydraulic 4-Roll Plate Bending Rolls

Established in 1959 and with particular emphasis on hydraulic bending rolls since the early 1980’s, MG are world leading manufacturers of plate bending machines. The current range is the result of continuous research and development over the years and represents the highest level of technology in this field. With capacity to manufacture machines in the range of 200mm to 8000mm bending length and 1mm to 300mm bending capacity, MG has a solution for virtually every requirement. The 4-Roll ‘Series M’ models are of double pinch design, with additional bottom roll, and have been produced using high quality components, benefiting from MG’s proven technology, allowing maximum performance while still requiring little maintenance over the life of the machine. The 4-Roll design, with continuous pinching of the material, provides the option of fitting an NC or CNC control, therefore allowing the automation of the bending process.

| MODEL | STOCK CODE | BENDING LENGTH | ROLLING CAPACITY | PRE BENDING | TOP ROLL dia | BOTTOM ROLL dia | SIDE ROLLS dia | WORKING HEIGHT | MOTOR | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | mm | mm | mm | mm | kw | mm | mm | mm | kg | ||

| M 0501 L | 21843 | 550 | 1.5 | 1 | 70 | 120 | 115 | 600 | 2.2 | 1,424 | 625 | 776 | 800 |

| M 1003 L | 21844 | 1050 | 3 | 2 | 90 | 120 | 105 | 600 | 2.2 | 1,924 | 625 | 776 | 1000 |

| M 1206 P | 21845 | 1250 | 6 | 4 | 120 | 115 | 105 | 695 | 2.2 | 2,435 | 845 | 1,030 | 1500 |

| M 1504 P | 21846 | 1550 | 4 | 3 | 130 | 120 | 105 | 695 | 2.2 | 2,735 | 845 | 1600 | |

| M 1706 P | 21847 | 1750 | 6 | 4 | 150 | 130 | 120 | 700 | 3 | 2,935 | 845 | 1,030 | 1700 |

| M 2004 P | 21848 | 2050 | 4 | 2 | 140 | 130 | 105 | 705 | 3 | 3,235 | 845 | 1,030 | 1900 |

| M 2006 P | 21849 | 2050 | 6 | 4 | 160 | 140 | 120 | 710 | 3 | 3,235 | 845 | 1,030 | 2100 |

| M 2008 A | 21850 | 2050 | 8 | 6 | 190 | 170 | 150 | 805 | 3 | 3,370 | 1,050 | 1,245 | 3400 |

| M 2010 R | 21851 | 2050 | 10 | 8 | 210 | 190 | 160 | 860 | 4 | 3,160 | 1,060 | 1,320 | 3800 |

| M 2014 R | 21852 | 2050 | 14 | 10 | 220 | 200 | 170 | 865 | 5.5 | 3,160 | 1,060 | 1,320 | 4200 |

| M 2020 C | 21853 | 2050 | 20 | 14 | 280 | 260 | 210 | 995 | 7.5 | 3,425 | 1,460 | 1,520 | 5000 |

| M 2028 D | 21854 | 2050 | 28 | 20 | 320 | 300 | 230 | 1080 | 11 | 3,624 | 1,720 | 1,830 | 8000 |

| M 2038E | 21855 | 2050 | 38 | 30 | 370 | 350 | 270 | 1395 | 15 | 4,290 | 1,980 | 14000 | |

| M 2045 F | 21856 | 2050 | 45 | 35 | 420 | 390 | 310 | 1725 | 22 | 4,555 | 2,180 | 2,385 | 15000 |

| M 2050 G | 21857 | 2050 | 50 | 40 | 430 | 420 | 360 | 1835 | 30 | 5,090 | 2,695 | 2,450 | 16000 |

| M 2060 H | 21858 | 2050 | 60 | 50 | 520 | 500 | 430 | 2235 | 37 | 5,000 | 2,900 | 3,065 | 32000 |

| M 2075 I | 21859 | 2050 | 75 | 60 | 570 | 560 | 510 | 2570 | 56 | 5,300 | 3,480 | 3,570 | 30000 |

| M 2100 Y | 21860 | 2050 | 100 | 75 | 610 | 590 | 520 | 2655 | 75 | 5,300 | 3,480 | 3,570 | 42000 |

| M 2506 P | 21861 | 2600 | 6 | 4 | 180 | 170 | 140 | 710 | 3 | 3,785 | 845 | 1,030 | 3500 |

| M 2508 A | 21862 | 2600 | 8 | 6 | 200 | 180 | 150 | 805 | 3 | 3,920 | 1,050 | 1,245 | 4000 |

| M 2510 R | 21863 | 2600 | 10 | 8 | 220 | 210 | 170 | 860 | 4 | 3,975 | 1,060 | 1,320 | 4500 |

| M 2514 B | 21864 | 2600 | 14 | 10 | 240 | 220 | 190 | 870 | 5.5 | 3,975 | 1,210 | 1,320 | 6500 |

| M 2520 C | 21865 | 2600 | 20 | 15 | 280 | 260 | 220 | 990 | 7.5 | 3,975 | 1,460 | 1,520 | 7000 |

| M 2528 D | 21866 | 2600 | 28 | 20 | 340 | 320 | 230 | 1090 | 11 | 4,720 | 1,720 | 1,830 | 10000 |

| M 2538 E | 21867 | 2600 | 38 | 30 | 400 | 380 | 300 | 1420 | 15 | 5,340 | 1,980 | 2,090 | 17000 |

| M 2540 F | 21868 | 2600 | 40 | 35 | 410 | 390 | 310 | 1725 | 22 | 5,055 | 2,180 | 2,385 | 19000 |

| M 2550 G | 21869 | 2600 | 50 | 40 | 510 | 460 | 390 | 1850 | 30 | 5,640 | 2,695 | 2,450 | 24000 |

| M 2565 H | 21870 | 2600 | 65 | 50 | 520 | 480 | 410 | 2245 | 37 | 5,640 | 3,130 | 3,065 | 33000 |

| M 2575 I | 21871 | 2600 | 75 | 60 | 570 | 530 | 440 | 2625 | 56 | 5,850 | 3,480 | 3,570 | 40000 |

| M 2590 Y | 21872 | 2600 | 90 | 70 | 680 | 630 | 490 | 2655 | 75 | 5,850 | 3,480 | 3,570 | 50000 |

| M 3006 A | 21873 | 3100 | 6 | 4 | 210 | 190 | 150 | 805 | 3 | 4,420 | 1,050 | 1,245 | 4500 |

| M 3008 R | 21874 | 3100 | 8 | 6 | 230 | 220 | 170 | 860 | 4 | 4,475 | 1,060 | 1,320 | 5500 |

| M 3010 B | 21875 | 3100 | 10 | 8 | 250 | 230 | 190 | 870 | 5.5 | 4,475 | 1,210 | 1,320 | 6000 |

| M 3015 C | 21876 | 3100 | 15 | 13 | 290 | 270 | 210 | 985 | 7.5 | 4,475 | 1,460 | 1,520 | 8000 |

| M 3018 C | 21877 | 3100 | 18 | 14 | 310 | 280 | 230 | 995 | 11 | 4,475 | 1,460 | 1,520 | 9000 |

| M 3022 D | 21878 | 3100 | 22 | 18 | 350 | 330 | 250 | 1090 | 11 | 5,220 | 1,720 | 1,830 | 13000 |

| M 3028 M | 21879 | 3100 | 28 | 22 | 380 | 360 | 270 | 1415 | 15 | 4,760 | 1,924 | 2,005 | 17000 |

| M 3035 E | 21880 | 3100 | 35 | 26 | 430 | 380 | 300 | 1420 | 18.5 | 5,340 | 1,980 | 2,090 | 19000 |

| M 3038 F | 21881 | 3100 | 38 | 32 | 440 | 410 | 320 | 1740 | 22 | 5,555 | 2,180 | 2,385 | |

| M 3042 G | 21882 | 3100 | 42 | 34 | 460 | 420 | 360 | 1850 | 30 | 6,140 | 2,695 | 2,450 | 27000 |

| M 3048 G | 21883 | 3100 | 48 | 36 | 480 | 440 | 370 | 1860 | 30 | 6,140 | 2,695 | 2,450 | 29000 |

| M 3055 H | 21884 | 3100 | 55 | 40 | 540 | 510 | 430 | 2255 | 45 | 6,140 | 3,130 | 3,065 | 50000 |

| M 3065 I | 21885 | 3100 | 65 | 50 | 630 | 570 | 460 | 2655 | 56 | 6,350 | 3,480 | 3,570 | 66000 |

| M 3075 Y | 21886 | 3100 | 75 | 55 | 680 | 620 | 490 | 2655 | 75 | 6,350 | 3,480 | 3,570 | 71000 |

Capacities are given for 250 N/mm² plate yielding strength

Features

- 4-Roll double pinch design for pre-bending both sides of the plate before rolling

- Electro welded and stress relieved frame construction

- High quality European components used throughout

- Permanent lubrication system – all parts are lubricated and sealed during assembly

- C45 forged steel rolls, induction hardened

- Crowning on rolls to compensate for deflection during bending process

- Three rolls driven by hydraulic motors with gearboxes directly coupled to the rolls

- Planetary roll movement reducing friction and maintaining precision

- Rolls mounted on high load rated sealed double roller bearings

- Massive torsion bars with sophisticated hydraulic valves to ensure roll parallelism

- Hydraulic drop end and automatic top roll balancing for material removal

- Hydraulic up & down movement of the bending rolls

- Digital read out for side roll positions

- Cone bending system

- Laser alignment system for material positioning

- Safety system to conform to EU norms

- Mobile control console

Options

- Hydraulic overhead support

- Hydraulic side supports

- NC Control

- CNC Control