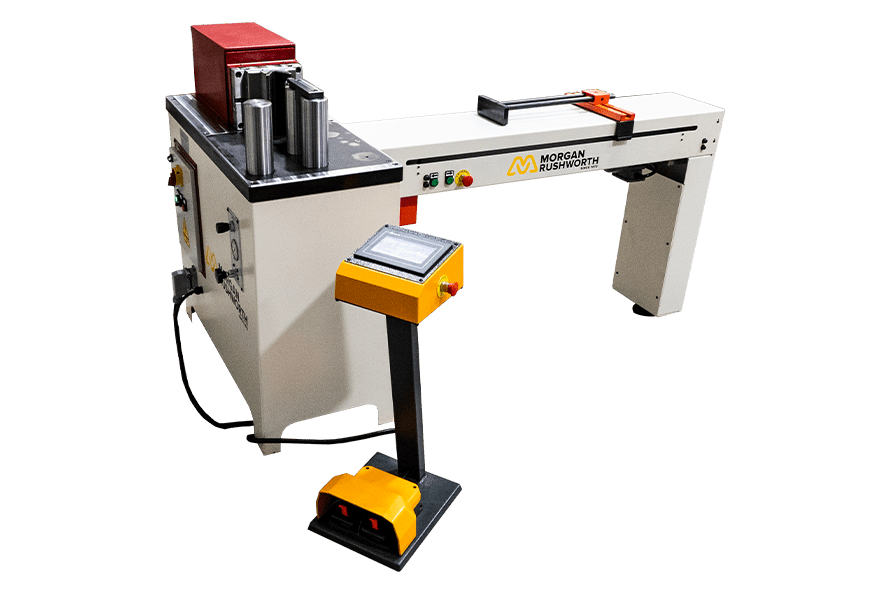

Morgan Rushworth HBM Horizontal Bending Press 415V With NC Controller

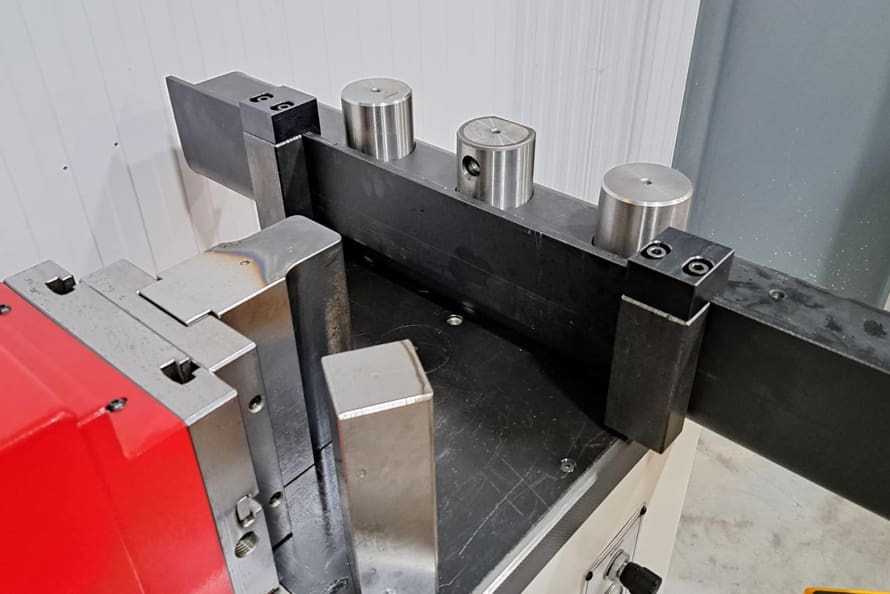

The Morgan Rushworth HBM Horizontal Bending Press range of machines are available with capacities from 10 ton up to 100 ton, fitted with an NC Controller for repeated bends. These machines have proved capable of performing a whole variety of bending applications. It is very easy to manufacture specialised tooling such as pipe bending, bar straightening and angle bending brackets and cleats. The forward and return bending stroke travel can be set with minimum travel, sufficient enough to reload the material therefore reducing cycle time.

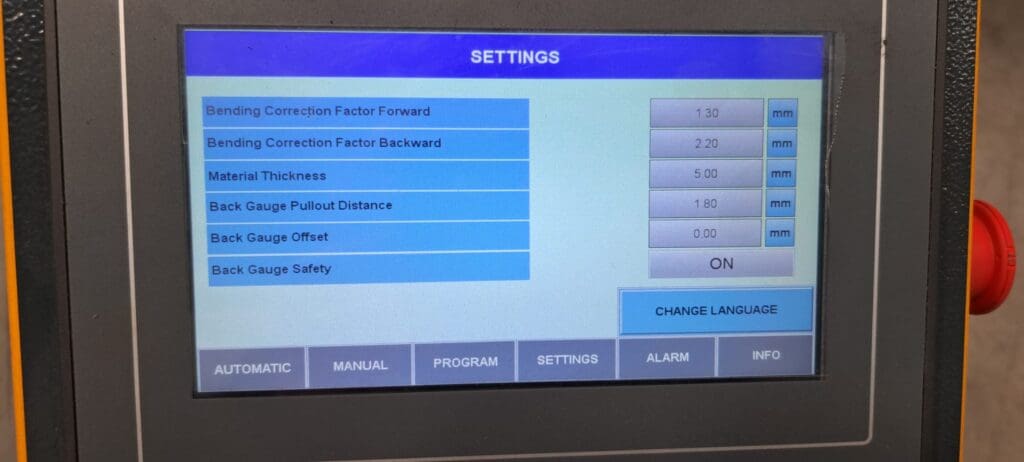

These machines are extremely adaptable and capable of a wide range of bending applications. Speak to us about your requirements, and what tooling you would need. The NC Controller is capable of storing 99 programmes, consisting of 15 steps each. The machine can also be fitted with an optional automatic back gauge for increased productivity.

Or why not browse our range of heavy duty press brakes too?

| MODEL | HBM 10/150 | HBM 20/200 | HBM 30/250 | HBM 40/250 | HBM 50/300 | HBM 80/300 | HBM 100/300 | |

| STOCK CODE | M4520NC | M4521NC | M4522NC | M4523NC | M4524NC | M4525NC | M4526NC | |

| Max Pressure at 200 Bars | ton | 10 | 20 | 30 | 40 | 50 | 80 | 100 |

| Oil Tank Capacity | lt | 12 | 12 | 40 | 40 | 60 | 120 | 120 |

| Bending Capacity Flat Material | mm | 150 x 8 | 200 x 12 | 250 x 12 | 250 x 24 | 300 x 15 | 300 x 20 | 300 x 25 |

| Bending Capacity Round Tubes | mm | 42 x 3.2 | 48 x 4.0 | 60 x 4.0 | 60 x 5.0 | 76 x 4.0 | 90 x 9 | 114 x 10 |

| Max Stroke | mm | 185 | 185 | 285 | 285 | 285 | 285 | 285 |

| Diameter of Bolts | mm | 60 | 80 | 80 | 80 | 90 | 105 | 105 |

| Height of Toolings | mm | 150 | 200 | 250 | 250 | 300 | 300 | 300 |

| Working Speed | mm/sec | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Return Speed | mm/sec | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Motor Power | kw | 1.1 | 2.2 | 3 | 4 | 5.5 | 10 | 10 |

| Net Weight | kg | 250 | 530 | 1050 | 1050 | 1450 | 1700 | 1700 |

| Size of the Table (LxW) | mm | 450 x 900 | 480 x 1060 | 660 x 1250 | 660 x 1250 | 600 x 1250 | 750 x 1425 | 750 x 1425 |

| Working Height | mm | 915 | 930 | 930 | 930 | 930 | 930 | 930 |

| Length of the Machine | mm | 900 | 1150 | 1250 | 1250 | 1400 | 1430 | 1430 |

| Width of the Machine | mm | 450 | 480 | 650 | 650 | 600 | 750 | 750 |

| Height of the machine | mm | 1130 | 1200 | 1250 | 1250 | 1500 | 1450 | 1450 |

| Size of Packing (LxWxH) | mm | 100 x 500 x 1500 | 600 x 1150 x 1700 | 700 x 1280 x 1750 | 700 x 1280 x 1750 | 1450 x 650x 1800 | 1500 x 750 x 1800 | 1500 x 750 x 1800 |

Features

- Built according to EC Safety Directives (CE-Mark Approved)

- Heavy duty frame

- Stroke adjustment by digital readout

- Manual or automatic working system

- All tooling and pins are induction hardened and ground

- Operation by foot pedal

- 1 set of flat bar bending tooling as standard

- Tooling height 150-300mm

- NC Controller consisting of up to 99 programmes, with up to 15 steps each.

- Extremely adaptable and capable of a wide range of bending applications

- Stroke regulation by means of sensitive electric limit switches

- Adjustable bending pressure

- Large range of special tooling available

- Ideal for one off or production applications

- 1 years warranty

Options

- Cutting, punching, straightening, pipe bending tools are available

- Upgrade to an automatic back-gauge for additional productivity

The Hidden Dangers of Aluminium Dust from High-Speed Cutting

27th August 2024 by Dave Hargest

5 Key Factors to Consider when Purchasing Metalworking Machinery

11th March 2024 by Dave Hargest

4 Useful aspects of Sheet Metal Vacuum Lifters

21st December 2023 by Dave Hargest

5 Key Criteria to Consider for Vacuum Lifting

21st December 2023 by Dave Hargest

Lifting Magnets vs Vacuum Lifting

21st December 2023 by Dave Hargest

How Does an IPG LightWELD Laser Welder Compare to Traditional MIG or TIG Welding?

26th September 2023 by Dave Hargest

Laser Welding – Frequently Asked Questions

11th September 2023 by Dave Hargest

How to use the HBM Horizontal Bending Press Digital Read Out System

18th June 2018 by Clare Harris

Coleg Gwent – Machinery for the next generation

14th November 2023 by Dave Hargest

Coleg Gwent is Wales' largest further education and one of the best-performing colleges, delivering a wide range of part-time and full-time academic and vocational courses to over 16,000 students annually... More

MMK Engineering – Bringing Profiling In-House

13th October 2023 by Dave Hargest

MMK Engineering Ltd, based in Devon, work across the full spectrum of engineering, from designing small components to assembling entire end-use products and machinery. We spoke to Rob Jeffrey, Design.. More

6IX Process Design Ltd uprate their machinery with Selmach

14th September 2022 by Dave Hargest

6IX Process Design Ltd, based in Somerset, are manufactures of stainless steel tanks, vessels and processing systems for the brewing and dairy industries. We spoke to Sam Cabell, Managing Director.. More

MR Industrial Services continued success with the help of Selmach Machinery

6th September 2022 by Dave Hargest

MR Industrial Services, based in Corby, Northamptonshire supply a range of architectural and industrial steelwork to the construction industry. We spoke to Carl Peters, Martyn Nimmo and William Adams to.. More