Morgan Rushworth HBM Horizontal Bending Press 415V

The Morgan Rushworth HBM Horizontal Bending Press range offers capacities from 10 to 200 tons, making them suitable for a variety of bending applications. These machines support specialised tooling, including pipe bending, bar straightening, and angle bending for brackets and cleats. Adjustable stroke settings minimise travel for quick material reloading, reducing cycle times and increasing efficiency.

Built for adaptability, the HBM range handles diverse bending tasks with precision. Contact us to discuss your requirements and tooling options, or explore our heavy-duty press brakes for additional solutions.

HBM 80

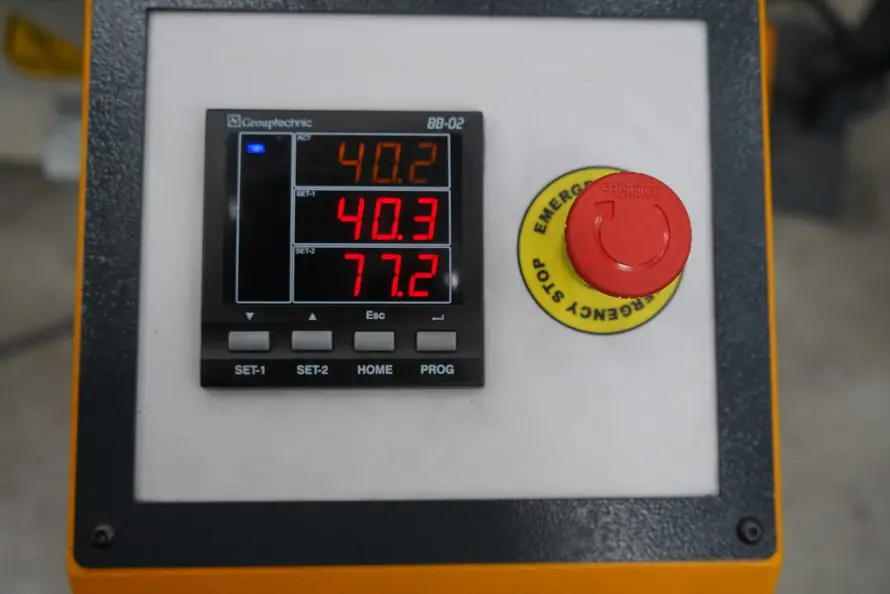

DRO Controller

Measured Rule Stop

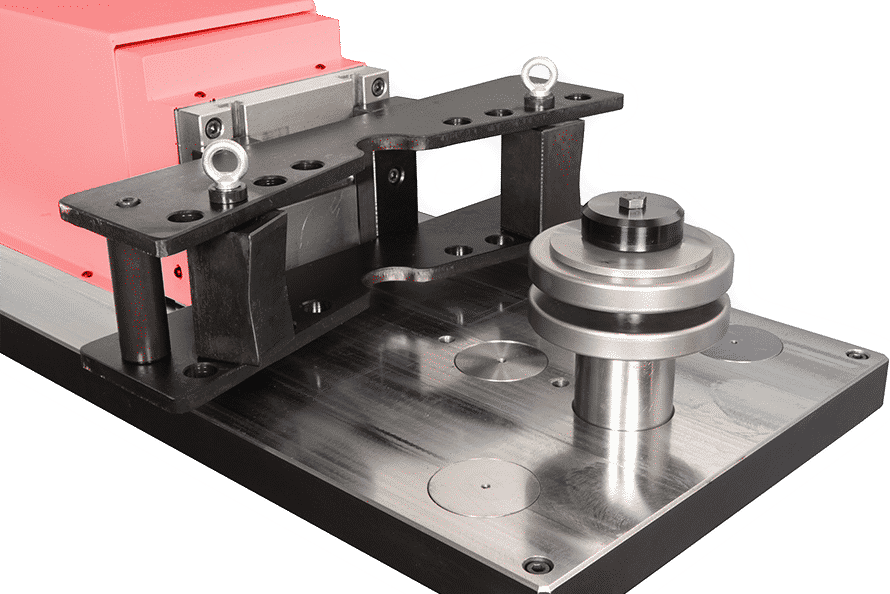

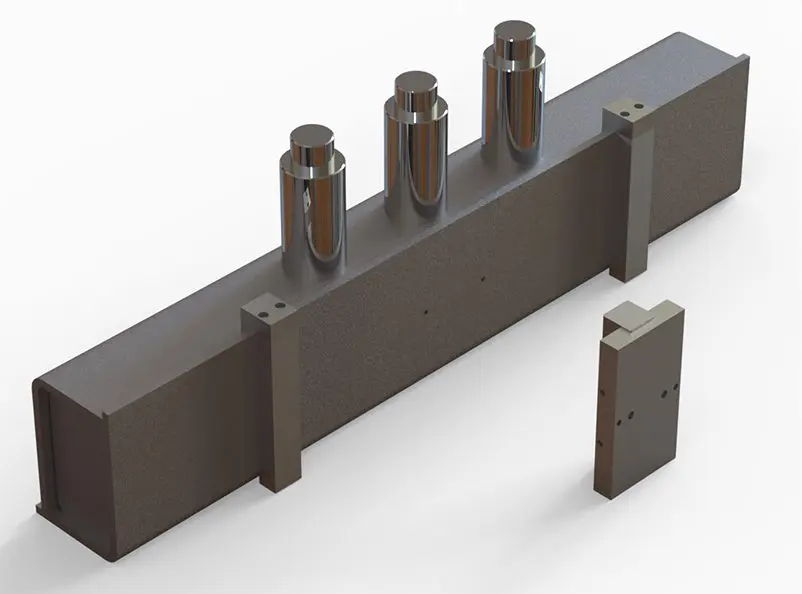

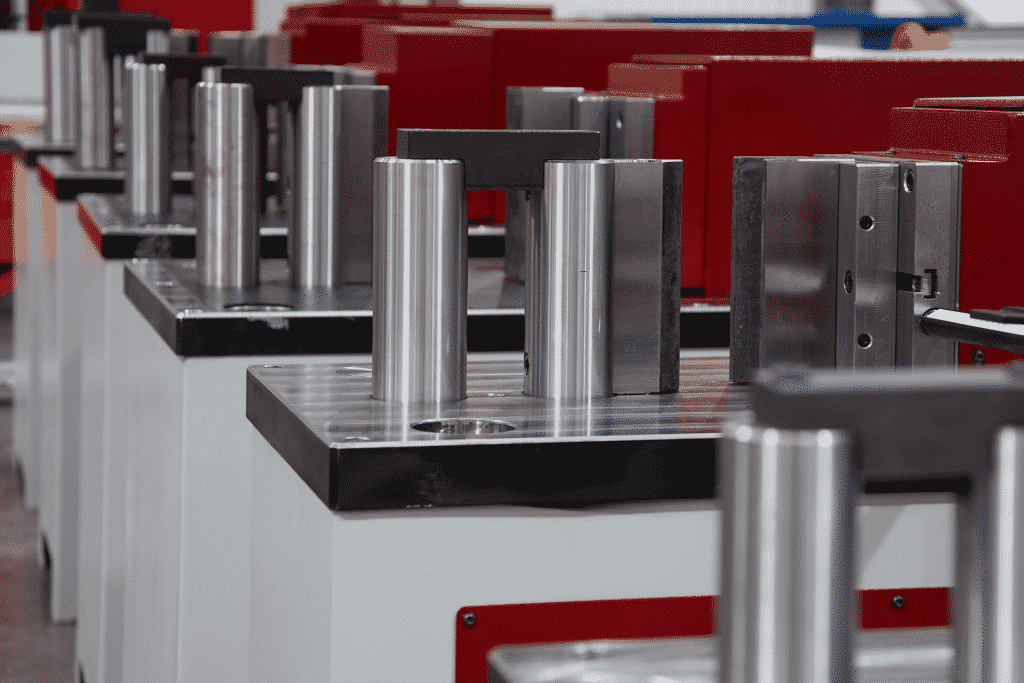

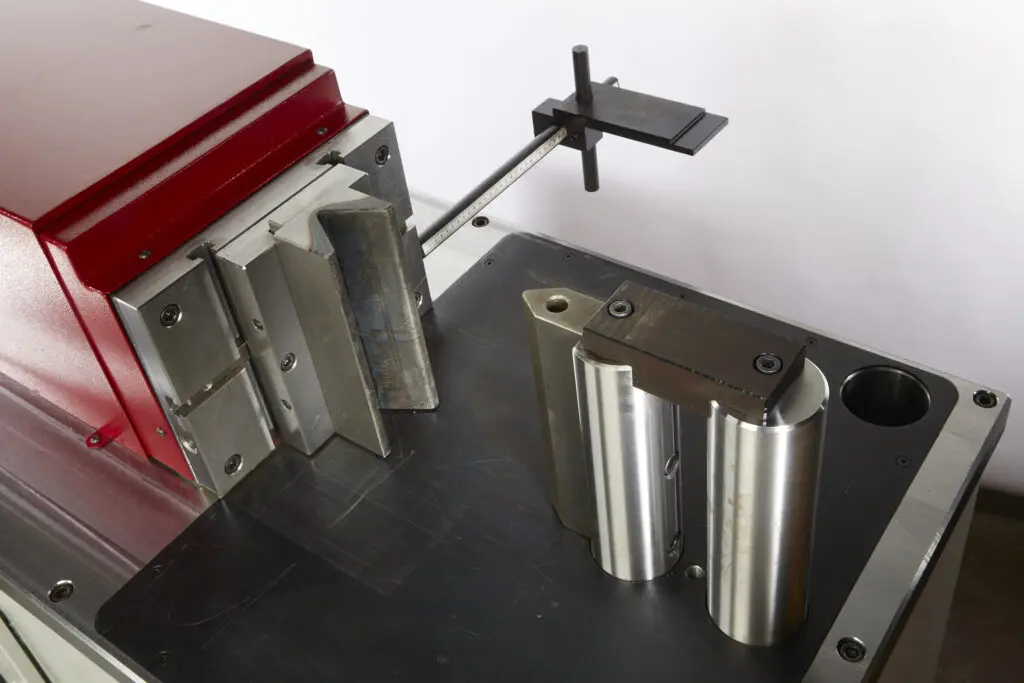

Standard Tooling

Standard Tooling

Bolt Punch and Multi-V Die

Tube Bending Tooling

Flat Bar Bending Tooling

Bar Straightener with adjustable material stops and a long (for thinner material) and short punch (for thicker material)

Bar Straightener with adjustable material stops and a long (for thinner material) and short punch (for thicker material)

Straightening Tooling

Examples of Folds

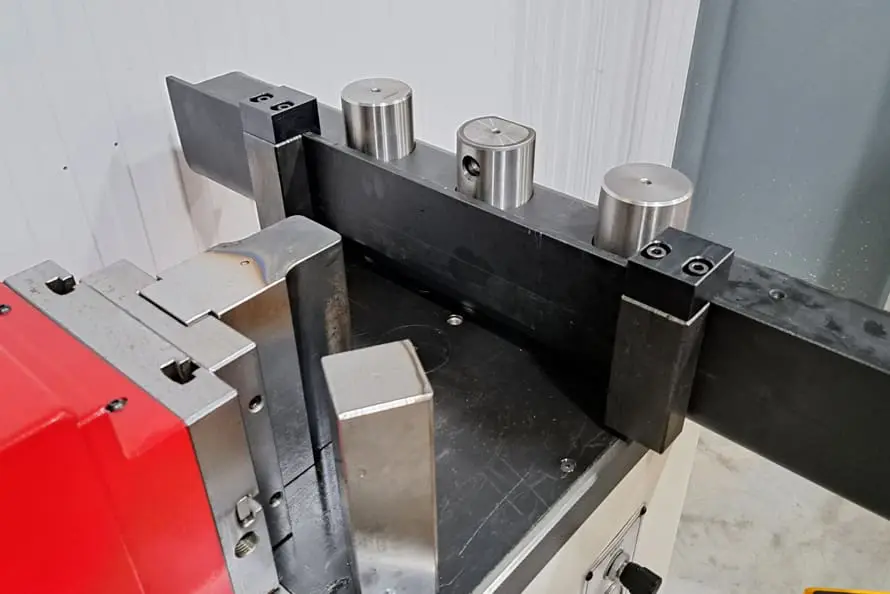

Standard Tooling Set-Up

| MODEL | HBM 10/150 | HBM 20/200 | HBM 30/250 | HBM 40/250 | HBM 50/300 | HBM 80/300 | HBM 100/300 | HBM 200/700 | |

| STOCK CODE | M4520 | M4521 | M4522 | M4523 | M4524 | M4525 | M4526 | M4527 | |

| Max Pressure at 200 Bars | ton | 10 | 20 | 30 | 40 | 50 | 80 | 100 | 200 |

| Oil Tank Capacity | lt | 8 | 25 | 40 | 40 | 70 | 70 | 70 | 160 |

| Bending Capacity Flat Material | mm | 150 x 8 | 200 x 10 | 250 x 10 | 250 x 12 | 300 x 16 | 300 x 19 | 300 x 21 | 700 x 30 |

| Bending Capacity Round Tubes | mm | 42 x 3.2 | 48 x 4.0 | 60 x 4.0 | 60 x 5.0 | 76 x 4.0 | 90 x 9 | 114 x 10 | 219.1 x 5 |

| Max Stroke | mm | 185 | 200 | 285 | 285 | 300 | 315 | 315 | 450 |

| Diameter of Bolts | mm | 60 | 80 | 80 | 80 | 90 | 105 | 105 | 105 |

| Height of Toolings | mm | 150 | 200 | 250 | 250 | 300 | 300 | 300 | 700 |

| Working Speed | mm/sec | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Return Speed | mm/sec | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Motor Power | kw | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Net Weight | kg | 370 | 580 | 1050 | 1050 | 1550 | 2030 | 2100 | 9000 |

| Size of the Table (LxW) | mm | 450 x 900 | 480 x 1060 | 660 x 1250 | 660 x 1250 | 650 x 1335 | 750 x 1427 | 750 x 1427 | 1100 x 2725 |

| Working Height | mm | 915 | 930 | 930 | 930 | 930 | 930 | 930 | 930 |

| Length of the Machine | mm | 900 | 1150 | 1250 | 1250 | 1400 | 1430 | 1430 | 1755 |

| Width of the Machine | mm | 450 | 480 | 650 | 650 | 600 | 750 | 750 | 1100 |

| Height of the machine | mm | 1130 | 1200 | 1250 | 1250 | 1500 | 1450 | 1450 | 2725 |

| Size of Packing (LxWxH) | mm | 100 x 500 x 1500 | 600 x 1150 x 1700 | 700 x 1280 x 1750 | 700 x 1280 x 1750 | 1450 x 650x 1800 | 1500 x 750 x 1800 | 1500 x 750 x 1800 | 1800 x 1150 x 2800 |

Features

- Built according to EC Safety Directives (CE-Mark Approved)

- Heavy duty frame

- Stroke adjustment by digital readout

- Manual or automatic working system

- All tooling and pins are induction hardened and ground

- Operation by foot pedal

- 1 set of flat bar bending tooling as standard

- Tooling height 150-700mm

- Foot pedal complete with three position digital readout i.e. Actual position, Adjustable Forward Stroke Position and Adjustable Return Stroke Position

- Extremely adaptable and capable of a wide range of bending applications

- Stroke regulation by means of sensitive electric limit switches

- Adjustable bending pressure

- Large range of special tooling available

- Ideal for one off or production applications

- 1 years warranty

Options

- Cutting, punching, straightening, pipe bending tools are available