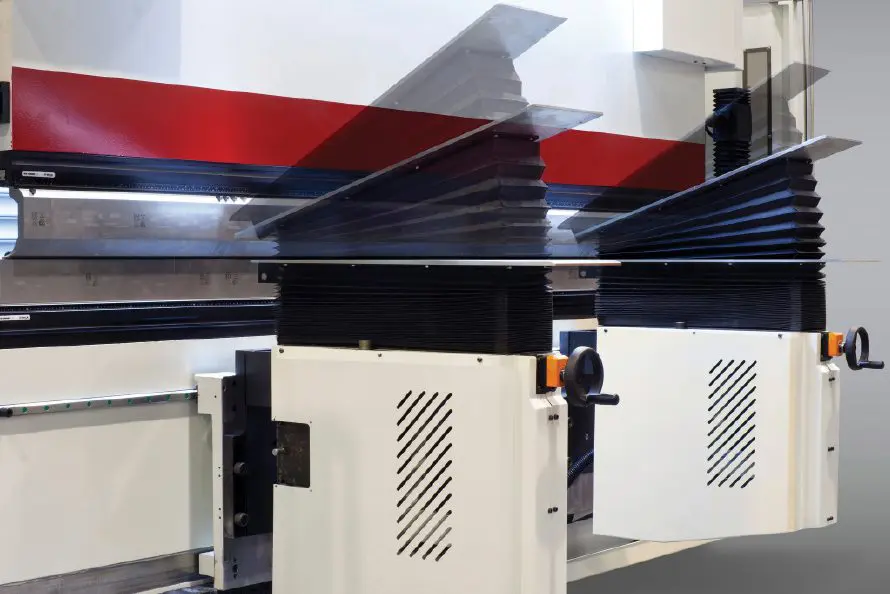

The Morgan Rushworth XPE and XPS servo electric press brakes represent a new standard in precision, energy efficiency, and reliability for sheet metal bending. Designed with advanced engineering principles, these machines deliver outstanding performance, making them an excellent choice for businesses seeking high-quality bending solutions. The XPE range utilises a belt and pulley system, while the XPS range features a ball and screw mechanism. Both systems ensure low energy consumption, high bending cycle speeds, and exceptional accuracy, offering significant advantages over conventional hydraulic press brakes.

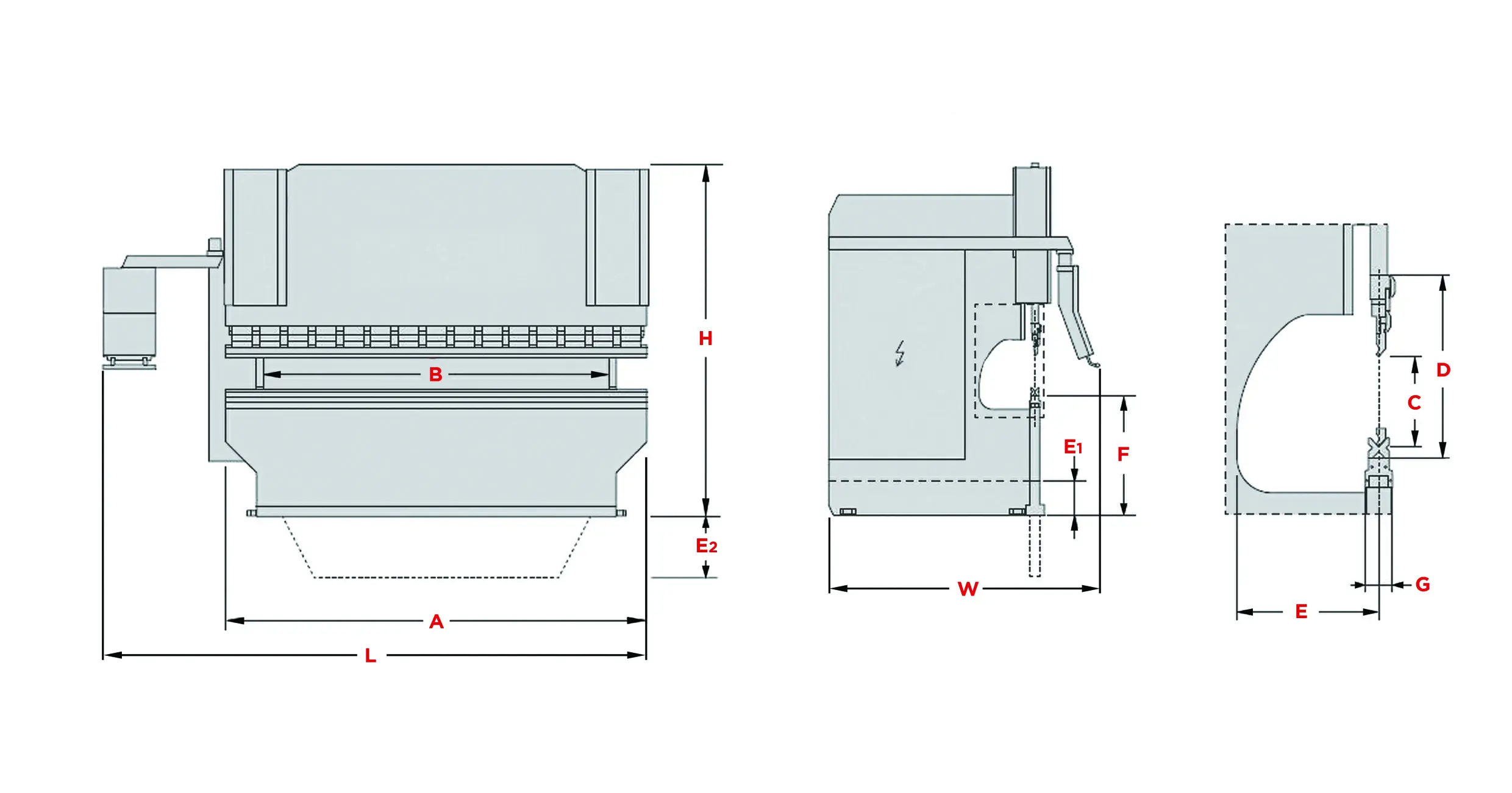

The range includes models spanning from 1530mm x 40T to 3100mm x 100T, ensuring there is a solution for a variety of applications. All models come equipped with the ESA VIS-875W 2D CNC touch screen controller, which simplifies programming and operation. This advanced control system allows operators to quickly set up jobs, optimise production workflows, and achieve consistent results with ease.

Superior Accuracy and Efficiency

A key feature of the XPE and XPS servo electric press brakes is their ability to deliver unmatched precision. The machines achieve a positioning accuracy of 0.01mm, which is far superior to traditional hydraulic systems. The O frame design minimises flex during operation, ensuring consistent pressure across the beam for precise and repeatable results. This level of accuracy is essential for applications requiring intricate or high-tolerance bends, making these machines ideal for industries such as aerospace, automotive, and precision manufacturing.

The servo-electric technology used in the XPE and XPS ranges also ensures energy efficiency. By eliminating hydraulic components such as rams, seals, pumps, and pipes, these machines consume significantly less energy during operation. This not only reduces operational costs but also contributes to a cleaner, more sustainable production environment.

Enhanced Productivity

The advanced design of the Morgan Rushworth XPE and XPS press brakes maximises productivity while minimising downtime. The consistent pressure provided by the belt and pulley or ball and screw systems ensures reliable performance across a wide range of materials and thicknesses. The side-mounted frames allow the backgauge to be used across the full width of the machine and to the maximum depth, providing greater flexibility for complex bending operations.

The ESA VIS-875W 2D CNC touch screen controller further enhances productivity by offering intuitive programming and graphical visualisation of bending operations. Operators can quickly input data, adjust settings, and monitor processes, reducing setup times and minimising the risk of errors. This ease of use ensures that even less experienced operators can achieve professional results, making the machines highly accessible.

Reliability and Low Maintenance

One of the standout benefits of the XPE and XPS servo electric press brakes is their exceptional reliability. Unlike hydraulic press brakes, which rely on a complex network of components such as rams, seals, and pumps, the servo-electric design is much simpler and more robust. By eliminating these hydraulic components, the machines significantly reduce the likelihood of leaks, wear, and other issues that can lead to downtime.

The result is a press brake that requires minimal maintenance, allowing businesses to focus on production without the interruptions associated with hydraulic systems. This reliability translates into lower operating costs over the machine’s lifespan, providing a strong return on investment for businesses of all sizes.

Versatility Across Applications

The versatility of the XPE and XPS servo electric press brakes makes them suitable for a wide range of applications. From simple bends to complex, high-precision projects, these machines deliver consistent performance and exceptional results. Their ability to handle a variety of materials and thicknesses ensures they can meet the demands of diverse industries, including construction, metal fabrication, and engineering.

With a range of models available, businesses can choose the machine that best fits their needs. The smaller models, such as the 1530mm x 40T, are ideal for compact workshops or smaller-scale projects, while the larger models, such as the 3100mm x 100T, provide the power and capacity needed for heavy-duty operations.

Customisation Options

Morgan Rushworth offers a range of customisation options for the XPE and XPS press brakes, allowing businesses to tailor the machines to their specific requirements. These options include specialised tooling, additional axis controls, and advanced backgauge configurations, ensuring the press brakes can handle even the most complex tasks.

By selecting the features that best match their operational needs, businesses can optimise their production processes and improve overall efficiency. This flexibility makes the XPE and XPS servo electric press brakes a future-proof investment that can adapt to evolving production demands.

Conclusion

The Morgan Rushworth XPE and XPS servo electric press brakes are a cutting-edge solution for modern sheet metal bending. Combining advanced servo-electric technology, precision engineering, and robust construction, these machines deliver superior accuracy, reliability, and energy efficiency. With a wide range of models and customisation options, they offer a versatile and cost-effective solution for businesses across various industries.

Whether you’re looking to upgrade from a hydraulic system or invest in a new press brake, the XPE and XPS ranges provide the performance and dependability you need. For more information or to discuss which model is right for your operation, contact our team today.