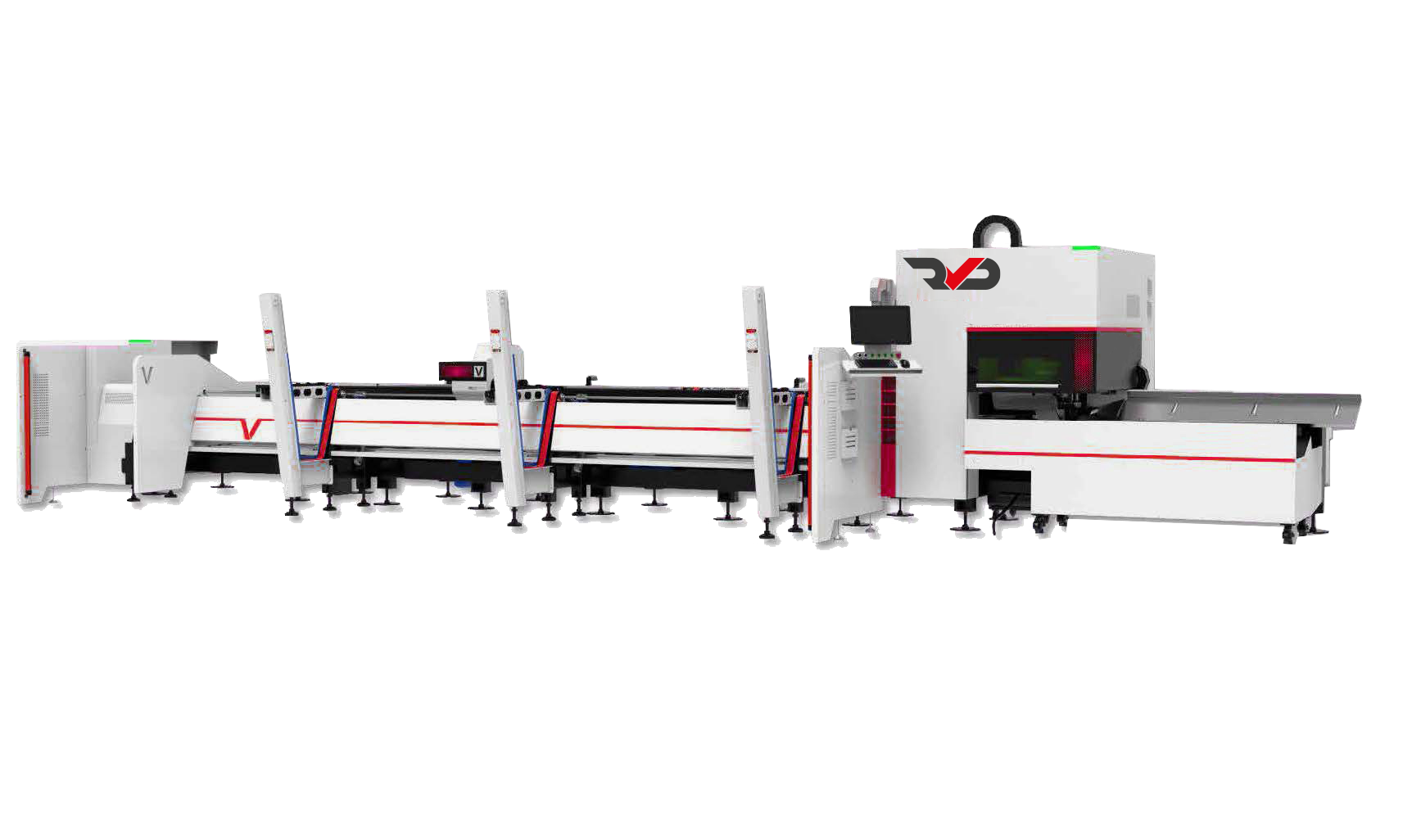

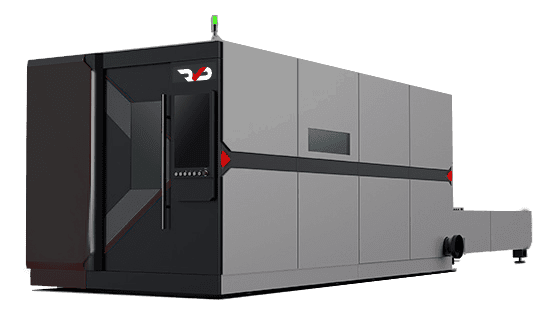

RVD Smart Fibre TF Tube Laser

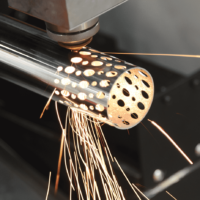

The RVD SmartFibre TF range of tube laser cutting machines offer an accurate, efficient and above all, cost-effective solution for industrial tube laser cutting, especially applicable for round, square, rectangular, oval and tubular profiles of impressively wide ranging lengths, diameters, materials and wall thicknesses.

The RVD Smart Fibre can easily hold its own amongst other laser cutting machines in its price range, easily handling tube lengths up to 8000mm and diameters up to an impressive up to an impressive 300mm.

State of the art CNC laser

State of the art Cypcut CNC laser control and software allow for the production of intricate components in an incredibly wide variety of tubular profiles, such as round tube, square tube, rectangular tube, oval tube, D-shaped steel ,T-shaped steel, H-shaped steel, channel steel, angle steel, etc.

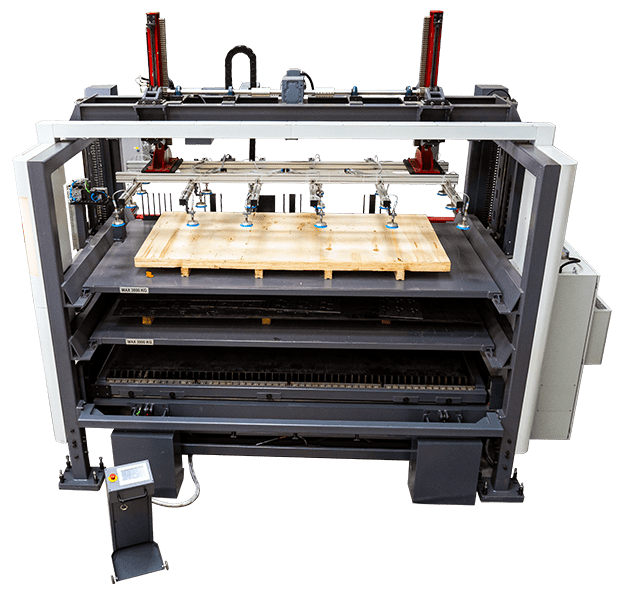

To further drive automation and productivity, The RVD Smart Fibre laser cutting machines can also be fitted with our optional magazine loading system, delivering true production line automation with the ability to process bundles of material up to an impressive 2500kg.

High performance accuracy

The high performance IPG / Max Photonics fibre laser source combines with the RVD Smart fibre laser’s fibre optic beam delivery system to offer laser cutting power from 1.5-4kW making cutting capacities for mild, galvanised and stainless steel, aluminium, brass and copper surprisingly impressive. The autofocus laser cutting head by RayTools of Switzerland and high precision class alpha rack and pinion drive motion system ensure that high power laser cutting isn’t just efficient, but also absolutely accurate.

Incorporating the world’s leading fibre laser resonator and electronic components sourced from industry leading brands to ensure superior stability. The bed provides outstanding rigidity whilst performing at high speed and acceleration, taking your tube laser cutting to the next level. The CE compliant complete machine enclosure and light barrier system ensures that the RVD Smart Fibre laser’s safety capabilities are just as impressive as its design and quality.

Specification Overview

- Cypcut CNC laser control and software

- IPG / Max Photonics fibre laser source

- RayTools autofocus laser cutting head

- Alpha rack and pinion drive motion system

- Optional magazine loading system

Find out more about the RVD TF Fibre Laser

![Morgan Rushworth BLT Tube Laser [Web]](https://selmach.com/wp-content/smush-webp/2022/12/Morgan-Rushworth-BLT-Tube-Laser-Web.png.webp)