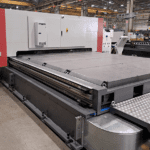

Morgan Rushworth XSM Fibre Laser Cutting Machines

The Morgan Rushworth XSM Fibre Laser Range features a moving laser cutting cabin, maximising cutting area while keeping a compact footprint. With power options from 3kW to 20kW, it delivers precise, high-speed cutting using a rigid gantry, robust frame, and advanced rack and pinion system.

Optional linear motors enhance acceleration, while the user-friendly CNC touch screen supports on-screen programming and PC imports. Built with premium components, the XSM range ensures superior cut quality, reliability, and minimal downtime.

| Bed Size | ASSORTED SIZES AVAIALBLE – MIN 2M X 6M / MAX 4M X 24M | ||

|---|---|---|---|

| X Axis Travel | mm | 6,000 – 24,000 (Depends on Bed Size) | |

| Y Axis Travel | mm | 2,000 – 4,000 (Depends on Bed Size) | |

| Z Axis Travel | mm | 100 | |

| Positioning Speed | Standard | m/min | 115 |

| Linear | m/min | 160 | |

| Axis acceleration | Standard | G | 2.8 |

| Linear | G | 3.2 | |

| Positioning accuracy | mm | 0.05 | |

| Length | mm | Depends on bed size | |

| Width | mm | Depends on bed size | |

| Height | mm | Depends on bed size | |

| Weight | kg | Depends on bed size | |

Features

- Class leading nLIGHT fibre laser source available from 3Kw – 20Kw

- Precitec ProCutter cutting head with auto focus and anti-collision functionality

- Beckhoff servo motors and drives

- Wittenstein rack and pinion system with automatic lubrication

- SMC automatic gas selection system

- Beckhoff touch screen controller with part graphic view and extensive cutting parameter data base

- Automatic sheet edge detection with skew allowance

- Automatic nozzle cleaning and calibration

- Class leading Lantek Expert software

- Mobile Cutting Cabin

- Large window viewing area with laser protective material

- Light guard protection for shuttle table

Options

- Auto nozzle changer

- CNC bevel cutting up to 45°

- Linear motors and drives instead of servo motors and drives

- CCTV view of cutting action

- Fume extractor with filters

- Air compressor and dryer

- Loading and unloading systems

The Morgan Rushworth XSM range of fibre lasers are available in a range of bed sizes and features a moving laser cutting cabin to allow the largest potential cutting area while maintaining a relatively compact footprint for the overall machine. Class leading components ensure superior cut quality, high reliability and reduced down time.

The range covers from 3kw up to 20kw which with the high performance rack and pinion system for X & Y axis and a rigid gantry and frame structure, resulting in fast acceleration, fast positioning speeds and fast cutting times. Optionally machines can be fitted with linear motors and guides for even greater acceleration. A user friendly touch screen CNC control allows parts to be programmed on the screen or imported from an office PC, providing flexible modes of operation.

The Morgan Rushworth XSM range of fibre lasers are offered in a wide range of different bed sizes, with widths from 2 – 4ms, and lengths anywhere from 6 all the way to 24m! The machines can be equipped with an assortment of different kW Laser Sources too.

Precitec ProCutter 2.0

The new ProCutter 2.0 generation impresses with its increased performance and new automation features. Faster, easier, more efficient, more enduring this is how laser cutting is shaping up in the new generation, due to numerous developments.

nLight Resonators

nLIGHT alta™ compact fibre lasers are the next generation of high power fibre lasers. Designed to meet the performance and reliability requirements for industrial applications, nLIGHT alta™ compact is the highest power, smallest footprint fibre laser. nLIGHT alta™ is capable of delivering a modulation rate up to 100 kHz and rise and fall time of less than 5s. Enabled by next generation electronics, these capabilities allow faster piercing, faster processing of fine features, and smaller heat affected zones.

LANTEK: Expert Cut II

LANTEK CAD/CAM system is specially designed to automate the programming of sheet metal cutting machines. Lantek software’s significant advance is meeting requirements of customers for managing sheet metal work process. The system will enable the user to carry out the following tasks:

- Import the parts to be cut in various ways (DXF format, ESSI format, etc.).

- Draw the parts with its user friendly drawing module.

- Import duct figures from other systems by means of ASCII files.

- Freely define the shape of the parts to be cut.

- Arrange all the parts generated on sheets manually or automatically and generate the cutting sequence for each one.

- Print standard or fully customized lists in order to provide estimates, VOB, frames list, delivery notes, workshop sheets, etc.

- Export the results to DXF format, ASCII tables, etc.

- Generate CNC programs automatically to transmit to the machines.

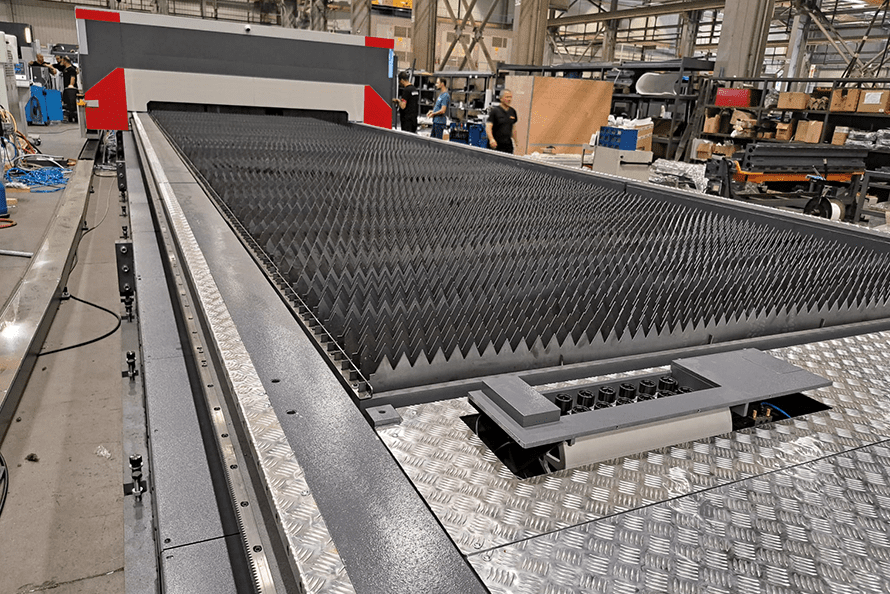

Moving Cabin System

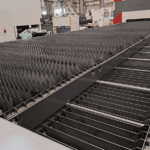

Rather than the traditional exchange tables of a 2 table laser, the moving cabin system of the XSM means there is just one large table, and the cutting cabin travels over the length of the bed. This means you can fit a relatively large laser into a much smaller footprint compared to an equivalent machine with an exchange table system. The system can be increased in length by increments of 1m compartments. The cabin utilises a dual linear rail system for both the cabin and the bridge gantry of the laser cutter, further minimising the footprint of the overall machine.

Cabin Parking Area

Rather than the space of a 2nd table, there is instead a cabin parking area the width of the table and 4m deep. This is where the cabin will “rest” between jobs, allowing full forklift or crane access to the cutting table for loading fresh sheets and unloading all of the cut-parts and skeleton.

Automatic Nozzle Changer

The optional Automatic Nozzle changing system is a game changer, allowing for fast and efficient cutting of multiple material sizes or thicknesses. Fast, efficient and labour-free, this speeds up production speeds and minimises the potential for human error.