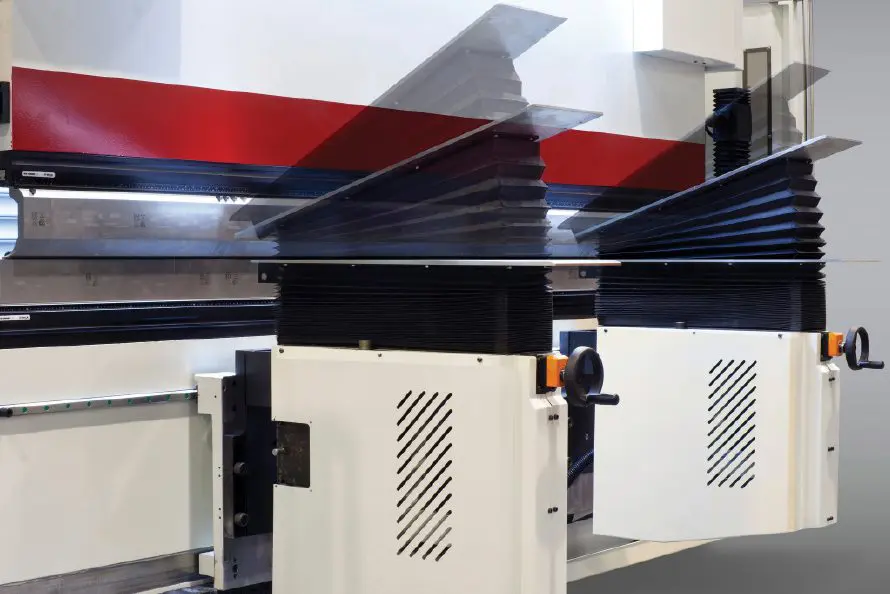

Morgan Rushworth PBSL Compact CNC Hydraulic Sheet Metal Press Brake

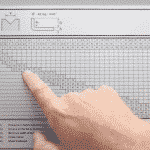

The Morgan Rushworth PBSL CNC press brakes feature an ESA S 640 CNC control with a 15” touch screen for numerical and 2D graphical programming. Bending is visualised in 2D, showing the machine frame, tools, and part orientation, with PC-based software allowing programs to be loaded from the office via networking.

These models offer 3-axis CNC control of the ram cylinders and back gauge, with high-precision scales ensuring synchronisation and ram parallelism. Standard features include AKAS laser guards, euro-style top tools, and a multi-vee bottom die, with options for crowning systems and CNC-controlled R-axis.

Standard Rear Backgauge Finger

X+R Axis Backgauge Fingers (Optional)

R-axis CNC (Optional)

Manual Anti Deflection Table (Optional )

Quick Release Tooling Clamps (Optional)

Laser Light Guard Protection

Sheet Support Arms

Sheet Follower Arms (Optional)

Manual Crowning (Optional)

CNC Crowning (Optional)

Back of the machine

ESA 640 Controller

ESA 660 Touch Control Panel (Optional)

| BENDING POWER | BENDING LENGTH | DIST BETWEEN COLUMNS | Y RAPID SPEED | Y WORKING SPEED | Y RETURN SPEED | TRAVEL IN X AXIS | SPEED OF X AXIS | TRAVEL IN R AXIS (OPTIONAL) | SPEED OF R AXIS (OPTIONAL) | NO. OF BACKGUAGE FINGERS | NO. OF SHEET SUPPORT ARMS | OIL CAPACITY | MOTOR POWER | STROKE | DAYLIGHT | THROAT DEPTH | TABLE HEIGHT | TABLE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT | |

| MODEL | Tonne | A mm | B mm | mm/sec | mm/sec | mm/sec | mm | mm/sec | mm | mm/sec | Litre | kw | C mm | D mm | E mm | F mm | G mm | L mm | W mm | H mm | kg | ||

| PBSL CNC 3100/120 | 120 | 3,100 | 2,550 | 160 | 10 | 130 | 600 | 150 | 160 | 150 | 2 | 2 | 140 | 11 | 180 | 375 | 255 | 850 | 60 | 3,850 | 1,185 | 2,250 | 5,500 |

| PBSL CNC 3100/160 | 160 | 3,100 | 2,550 | 160 | 10 | 130 | 600 | 150 | 160 | 150 | 2 | 2 | 140 | 15 | 180 | 375 | 255 | 850 | 60 | 3,850 | 1,185 | 2,250 | 6,650 |

| PBSL CNC 3100/200 | 200 | 3,100 | 2,550 | 160 | 10 | 130 | 600 | 150 | 160 | 150 | 2 | 2 | 140 | 18.5 | 210 | 445 | 255 | 850 | 60 | 3,850 | 1,325 | 2,550 | 7,800 |

Features

- ESA S640 multi-axis CNC control with numerical and 2D graphical programming and visualisation, mounted on a pendant arm

- Fully synchronised CNC control of left and right upper beam cylinder position – Y1 + Y2 axis

- CNC control of back gauge depth – X axis

- Manual adjustment of back gauge height – R axis

- Manual side to side movement of back gauge fingers – Z axis

- Back gauge fingers with fine depth adjustment, adjustable laterally on a linear rail

- Euro style top tool holders with wedge style intermediates

- Sectionalised goose neck top tool and multi vee bottom die

- AKAS laser tooling guards for enhanced ease of use

- High precision linear scales for measurement of the stroke depth

- Hydraulic ram travel guided in low friction slide ways

- High approach and return speeds for production bending

- Height adjustable front support arms

- Electrically interlocked side guards

Options

- CNC control of back gauge height – R axis

- Manual bottom tool crowning system with position counter

- CNC bottom tool crowning system

- Quick release top tool clamping system

- Additional back gauge fingers

- Additional front support arms