CMS Smartline Waterjet Cutter

The CMS Smartline waterjet offers all customers an entry level accurate, cost effective waterjet cutting system. Smartline is designed to redefine industry standards of excellence by improving operating efficiency, while maintaining CMS’ renowned reputation for unparalleled construction and working quality. It includes all the safety and performance features typical of CMS Waterjet machines, in a brand new, innovative, and compact design.

Easy Pump Pressure Intensifier

Jetpower EVO Pressure Intensifier

Greenjet Evo Intensifier

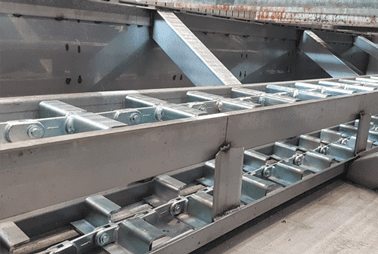

CMS Dredging System (Optional)

CMS Dredging System (Optional)

| Model | CMS Smartline | CMS Proline | ||

| Size | 2040 | 1730 | 2040 | |

| X Axis | mm | 4,000 | 4,250 | |

| Y Axis | mm | 2,000 | 2,000 | |

| Z Axis | mm | 250 (3-Axis) / 150 (5-Axis) | 300 (3-Axis) / 200 (5-Axis) | |

| B Axis (5 Axis Only) | ° |

±60 |

±62 | |

| C Axis (5 Axis Only) | N/A | Infinite | ||

| XY Axis Rapid Speed | mm/min | N/A | 40,000 | |

| Rest Surface | mm | 4150 x 2080 | 3700 x 2025 | 4650 x 2050 |

| Workable Load Capacity | kg/m2 | 500 | 1,000 | 1,000 |

| Position Accuracy | mm | +/- 0.1 | +/- 0.035 | |

| Position Repeatability (BS) | mm | +/- 0.05 | +/- 0.025 | |

| Installed Power | HP | 60 | 60 | |

| Overall Dimensions | mm | 5,595 x 7,400 x 4,000 | 7,152 x 3,183 x 4,1049 | 8,158 x 3,483 x 3,900 |

| Weight (Empty) | kg | 3,900 | 4,000 | 8,000 |

Features

- Mobile control panel with laptop

- New Z axis strokes up to 350mm 3 axis, up to 150mm 5 axis

- Easyjet DDX CAD/CAM Software

- Electronic hopper for abrasive automatic monitoring with sensors for cutting parameters automatic control

- Probe system for consistent cutting heights

- Integrated electric cabinet in the tank frame for a reduced footprint

- Bellows for X-Axis and labyrinth panels for Y-Axis to protect the linear guides and racks from water, dust and abrasives

- Aluminium cast uprights, welded steel bridge with reinforcement ribs

- Automatic lubrication of all axes

Options

- 60Hp Jetpower Evo Pressure Intensifier

- 4139 / 6200 Technocut Greenjet Evo Pressure Intensifier

- 21.5″ Touch Screen control panel on a mobile trolley

- Work area cleaning system

- Air conditioning for electrical cabinet

- Cross-Laser pointer

- Anti-collision feeler

- Drilling Unit

- Automatic hose reel

- Electronic Hopper

- Dredging system for “no maintenance” abrasive removal