Meyer Precision Centre Lathes

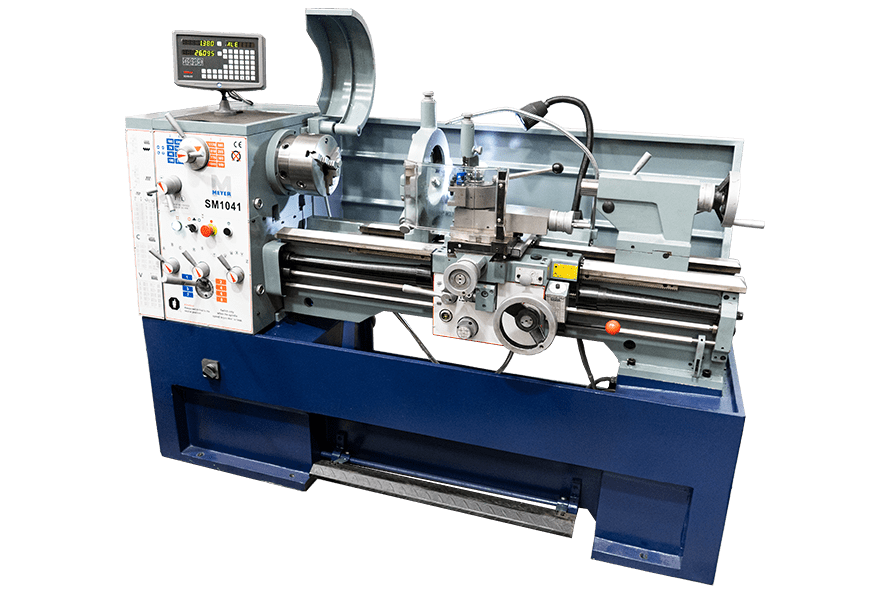

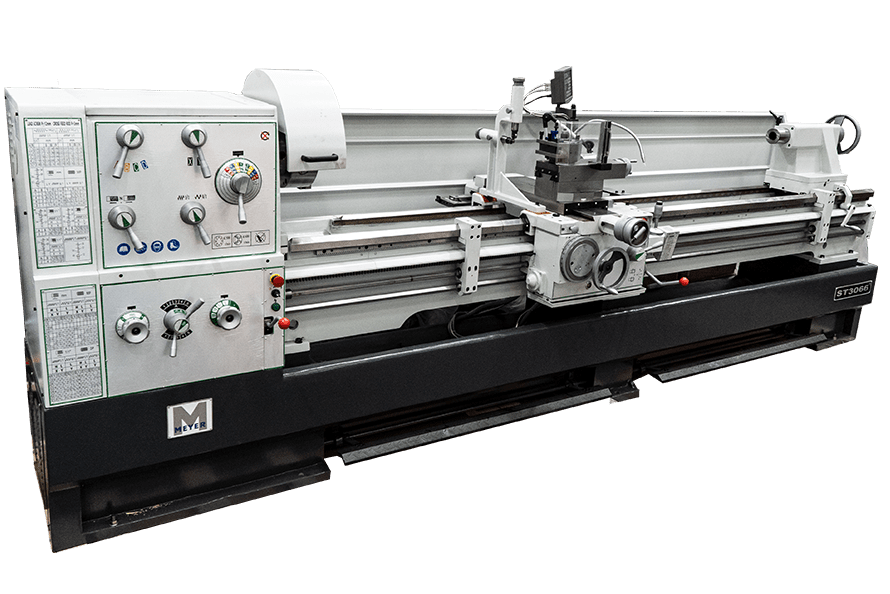

The Meyer Precision Lathes range from 360mm to 660mm swing capacities and from 1000mm to 4000mm distance between centres. The sturdy SB industrial lathes are ideal for the tool room and for jobbing operations. The heavy duty SG machines are available in eight different sizes and have the added benefit of 2-axis DRO and the super quick tool change system fitted as standard. The ST range are large capacity industrial lathes with a 660mm swing with the distances between centres available up to 4000mm. Power traverse is fitted as standard equipment to all ST models which are operator friendly for the longer length machines.

All Meyer industrial lathes are of the Gap Bed design with precision ground bed and saddle. Meyer machines are equipped with generous levels of standard equipment including 3 and 4 jaw chucks and face plate.

| SG1056 (1) | ||||||||

| SG1556 (2) | ST1566 (1) | |||||||

| SG1041 (1) | SG1046 (1) | SG2056 (3) | ST2066 (2) | |||||

| SB1036 | SM1041 | SG1541 (2) | SG1546 (2) | SG3056 (4) | ST4063 | ST3066 (3) | ||

| Capacities | ||||||||

| Swing over Bed | mm | 360 | 410 | 410 | 460 | 560 | 630 | 660 |

| Swing over Cross Slide | mm | 212 | 255 | 224 | 274 | 350 | 350 | 440 |

| Swing over Gap | mm | 491 | 580 | 640 | 690 | 788 | 830 | 900 |

| Length of Gap | mm | 210 | 250 | 155 | 155 | 200 | 230 | 250 |

| Distance between Centres (1) | mm | 1000 | 1000 | 1000 | 1000 | 1000 | 4000 | 1500 |

| Distance between Centres (2) | mm | – | – | 1500 | 1500 | 1500 | – | 2000 |

| Distance between Centres (3) | mm | – | – | – | – | 2000 | – | 3000 |

| Distance between Centres (4) | mm | – | – | – | – | 3000 | – | – |

| Width of Bed | mm | 187 | 250 | 300 | 300 | 350 | 550 | 400 |

| Feed Rates | ||||||||

| Longitudinal – no.of steps | – | 36 | 36 | 42 | 42 | 35 | 72 | 25 |

| Longitudinal – range | mm/rev | 0.050-0.696 | 0.050-0.696 | 0.031-1.7 | 0.031-1.7 | 0.059-1.646 | 0.048 – 24.3 | 0.022 – 0.74 |

| Cross – no.of steps | – | 36 | 36 | 42 | 42 | 35 | 72 | 25 |

| Cross – range | mm/rev | 0.013-0.188 | 0.013-0.188 | 0.014-0.784 | 0.014-0.784 | 0.02-0.573 | 0.024 – 12.15 | 0.044 – 1.48 |

| Max. Travel of Cross Slide | mm | 118 | 160 | 290 | 290 | 326 | 350 | 368 |

| Max. Travel of Compound Rest | mm | 68 | 68 | 120 | 120 | 130 | 200 | 230 |

| Thread Cutting | ||||||||

| Metric – no. of steps | – | 28 | 28 | 41 | 41 | 47 | 54 | 54 |

| Metric – range | mm | 0.2-5.0 | 0.2-5.0 | 0.1-14 | 0.1-14 | 0.2-14 | 1-240 | 0.45 – 120 |

| Imperial – no. of steps | – | 36 | 36 | 60 | 60 | 60 | 36 | 54 |

| Imperial – range | TPI | 8-112 | 8-112 | 2-112 | 2-112 | 2-112 | 28-1 | 7/16 – 80 |

| Diametric – no of steps | – | 36 | 36 | 50 | 50 | 50 | 27 | 42 |

| Diametric – range | DP | 8-112 | 8-112 | 4-112 | 4-112 | 4-112 | 30-1 | 7/8 – 160 |

| Module – no. of steps | – | 22 | 22 | 34 | 34 | 39 | 27 | 42 |

| Module – range | MP | 0.2-3 | 0.2-3 | 0.1-7 | 0.1-7 | 0.1-7 | 0.5 – 60 | 0.25- 60 |

| Lead Screw Pitch | mm | 3 | 3 | 6 | 6 | 6 | 12 | 2 or 12 |

| Headstock | ||||||||

| Spindle Nose | D1-4 | D1-6 | D1-6 | D1-6 | D1-8 | D-11 | D1-8 | |

| Spindle Bore | mm | 38 | 52 | 58 | 58 | 80 | 100 | 105 |

| Spindle Bore Taper | MT | 5 | 6 | 6 | 6 | 7 | 6 | 5 |

| Spindle Speeds – no. of steps | – | 8 | 16 | 12 | 12 | 12 | 18 | 16 |

| Spindle Speeds – range | rpm | 70-2000 | 45-1800 | 25-2000 | 25-2000 | 25-1600 | 14-750 | 26-1700 |

| Tailstock | ||||||||

| Quill Diameter | mm | 32 | 50 | 60 | 60 | 75 | 100 | 90 |

| Quill Travel | mm | 100 | 120 | 120 | 120 | 180 | 240 | 235 |

| Quill Taper | MT | 3 | 4 | 4 | 4 | 5 | 6 | 5 |

| Power | ||||||||

| Motor | kW | 1.5 | 3.3 | 4 | 4 | 7.5 | 11 | 7.5 |

| Dimensions | ||||||||

| Length (1) | mm | 1900 | 1940 | 2170 | 2170 | 2400 | 6000 | 3210 |

| Length (2) | mm | – | – | 2720 | 2720 | 2900 | – | 3710 |

| Length (3) | mm | – | – | – | – | 3400 | – | 4720 |

| Length (4) | mm | – | – | – | – | 3900 | – | |

| Width | mm | 700 | 850 | 1040 | 1040 | 1120 | 1600 | 1230 |

| Height | mm | 1250 | 1320 | 1340 | 1370 | 1460 | 1600 | 1600 |

| Weight (1) | kg | 670 | 1550 | 1670 | 1720 | 2020 | 6600 | 2800 |

| Weight (2) | kg | – | – | 1970 | 2020 | 2370 | – | 2950 |

| Weight (3) | kg | – | – | – | – | 2720 | – | 3320 |

| Weight (4) | kg | – | – | – | – | 3065 | – | – |

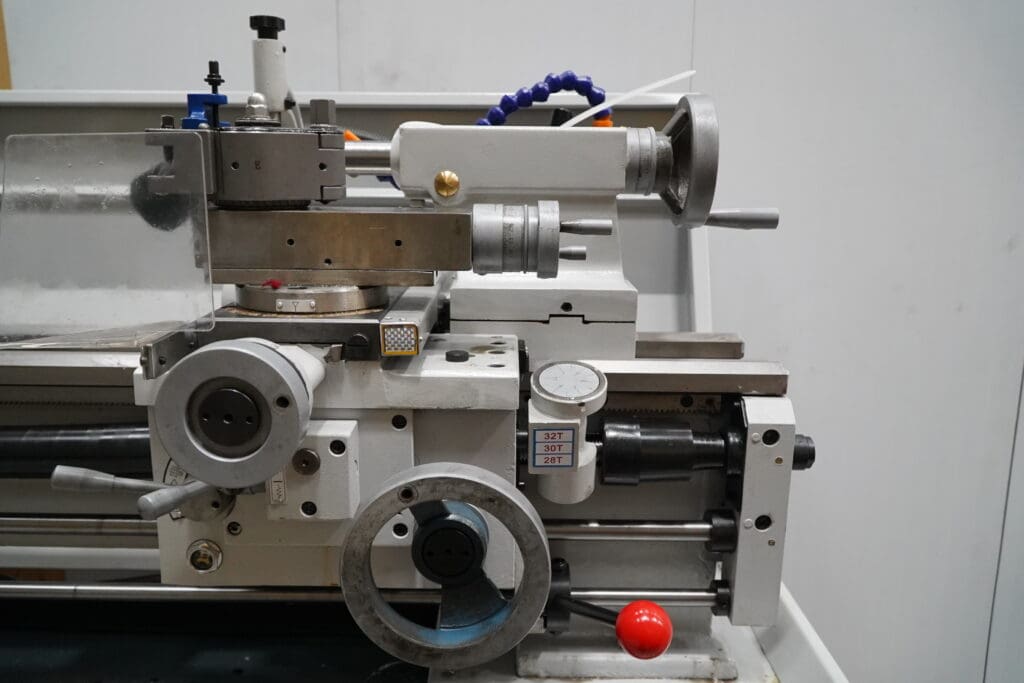

Features

- Heavy duty.

- Chuck guard with interlock switch.

- Halogen lamp.

- Steady rest

- Follow rest

- 4 jaw chuck.

- 3 jaw chuck.

- Face plate.

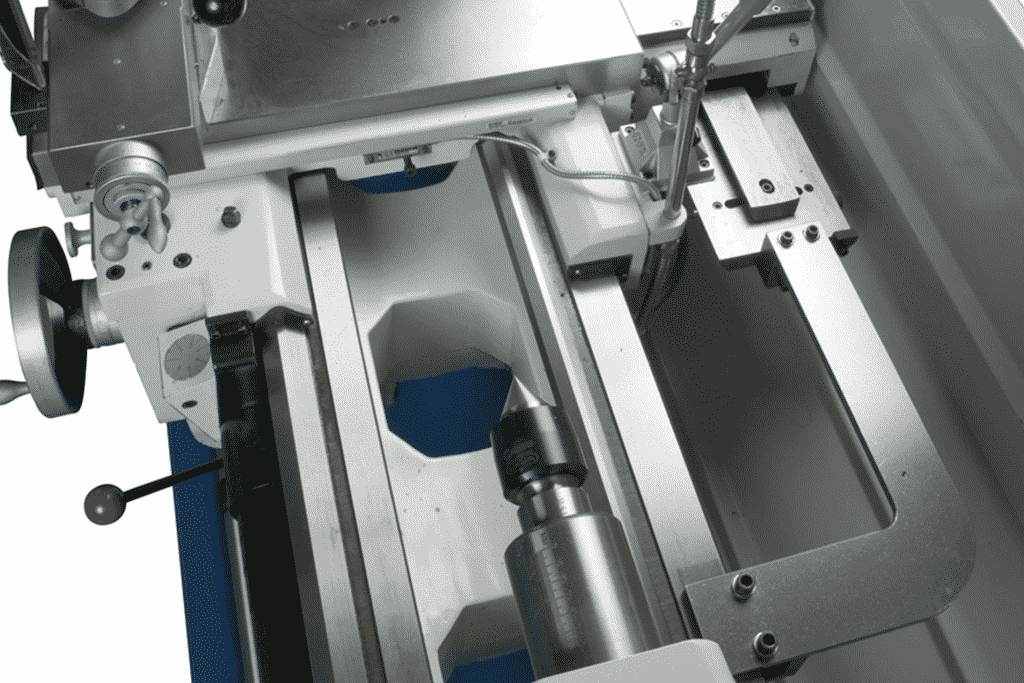

- Coolant system.

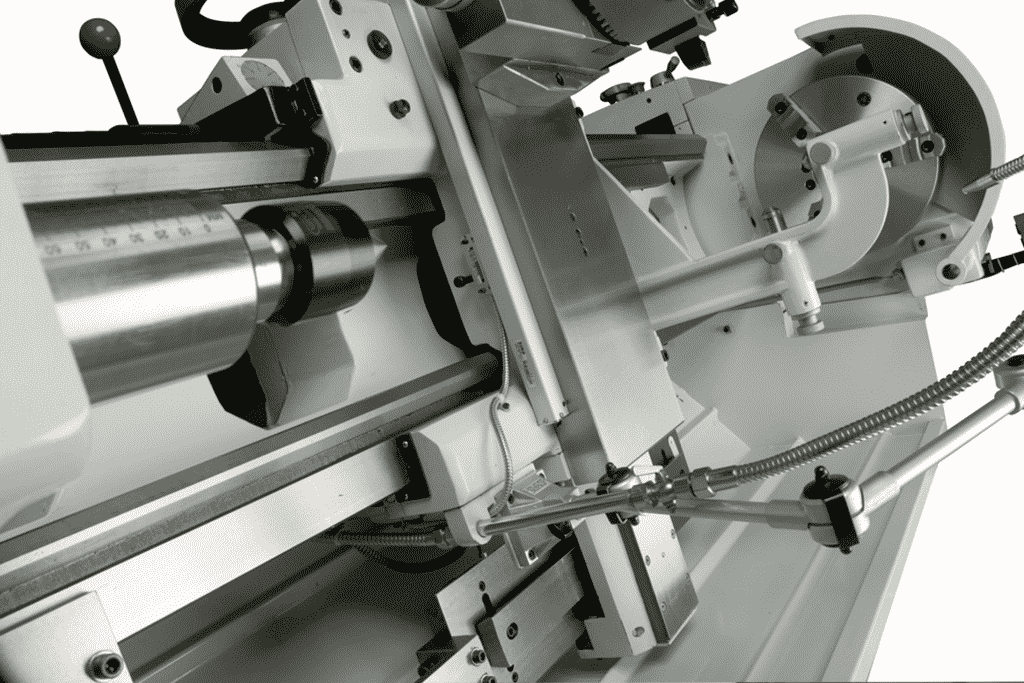

- 2 axis DRO

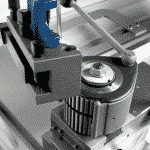

- Super quick tool change system with 4 holders

- ST – Power traverse

Options

- Taper turning attachment – SG/ST only.