Morgan Rushworth HDPX Range of High-Definition CNC Metal Cutting Plasma

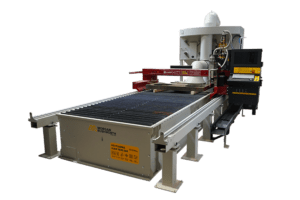

The HDPX High-Definition CNC plasma machine is the flagship model from Morgan Rushworth, available in a wide range of bed sizes and with numerous optional features. Its special bridge carrier design ensures precision cutting, even on extremely long bed models, and allows the addition of optional equipment such as extra plasma torches for increased productivity and single or multiple oxy torch units for cutting materials up to 300mm thick.

| XPR 170 | XPR 300 | ||

| Plasma Output | Amps | 30 – 170 | 30 – 300 |

| Pierce Capacity | |||

| Mild Steel – Argon Assist | mm | 40 | 50 |

| Mild Steel – Standard | mm | 35 | 45 |

| Stainless Steel | mm | 22 | 38 |

| Aluminium | mm | 25 | 38 |

| Severance | |||

| Mild Steel | mm | 60 | 80 |

| Stainless Steel | mm | 38 | 75 |

| Aluminium | mm | 38 | 50 |

| MODEL | STOCK CODE | TABLE WIDTH | TABLE LENGTH | X AXIS STROKE | Y AXIS STROKE | HEIGHT UNDER TORCH | TABLE HEIGHT | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||

| HDPX 1503/170 | M8980 | 1700 | 3200 | 2300 | 3200 | 300 | 750 | 5200 | 3750 | 2200 | 4000 |

| HDPX 1503/170 | M8981 | 2200 | 4800 | 2800 | 4200 | 300 | 750 | 6200 | 4250 | 2200 | 6000 |

| HDPX 2006/170 | M8982 | 2200 | 6400 | 2800 | 6200 | 300 | 750 | 8200 | 4250 | 2200 | 8000 |

| HDPX 2504/170 | M8983 | 2700 | 4800 | 3300 | 4200 | 300 | 750 | 6200 | 4750 | 2200 | 7000 |

| HDPX 2506/170 | M8984 | 2700 | 6400 | 3300 | 6200 | 300 | 750 | 8200 | 4750 | 2200 | 9000 |

| HDPX 3006/170 | M8985 | 3200 | 6400 | 3800 | 6200 | 300 | 750 | 8200 | 5250 | 2200 | 10000 |

| HDPX 3009/170 | M8986 | 3200 | 9600 | 3800 | 9200 | 300 | 750 | 11200 | 5250 | 2200 | 12000 |

| HDPX 3012/170 | M8987 | 3200 | 12800 | 3800 | 12200 | 300 | 750 | 14200 | 5250 | 2200 | 15000 |

| HDPX 3014/170 | M8988 | 3200 | 14400 | 3800 | 14200 | 300 | 750 | 16200 | 5250 | 2200 | 17000 |

| HDPX 4006/170 | M8989 | 4200 | 6400 | 4800 | 6200 | 300 | 750 | 8200 | 6250 | 2200 | 12000 |

| HDPX 4009/170 | M8990 | 4200 | 9600 | 4800 | 9200 | 300 | 750 | 11200 | 6250 | 2200 | 14000 |

| HDPX 4012/170 | M8991 | 4200 | 12800 | 4800 | 12200 | 300 | 750 | 14200 | 6250 | 2200 | 17000 |

| HDPX 4014/170 | M89392 | 4200 | 14400 | 4800 | 14200 | 300 | 750 | 16200 | 6250 | 2200 | 19000 |

| HDPX 1503/300 | M8966 | 1700 | 3200 | 2300 | 3200 | 300 | 750 | 5200 | 3750 | 2200 | 4000 |

| HDPX 2004/300 | M8967 | 2200 | 4800 | 2800 | 4200 | 300 | 750 | 6200 | 4250 | 2200 | 6000 |

| HDPX 2006/300 | M8968 | 2200 | 6400 | 2800 | 6200 | 300 | 750 | 8200 | 4250 | 2200 | 8000 |

| HDPX 2504/300 | M8969 | 2700 | 4800 | 3300 | 4200 | 300 | 750 | 6200 | 4750 | 2200 | 7000 |

| HDPX 2506/300 | M8970 | 2700 | 6400 | 3300 | 6200 | 300 | 750 | 8200 | 4750 | 2200 | 9000 |

| HDPX 3006/300 | M8971 | 3200 | 6400 | 3800 | 6200 | 300 | 750 | 8200 | 5250 | 2200 | 10000 |

| HDPX 3009/300 | M8972 | 3200 | 9600 | 3800 | 9200 | 300 | 750 | 11200 | 5250 | 2200 | 12000 |

| HDPX 3012/300 | M8973 | 3200 | 12800 | 3800 | 12200 | 300 | 750 | 14200 | 5250 | 2200 | 15000 |

| HDPX 3014/300 | M8974 | 3200 | 14400 | 3800 | 14200 | 300 | 750 | 16200 | 5250 | 2200 | 17000 |

| HDPX 4006/300 | M8975 | 4200 | 6400 | 4800 | 6200 | 300 | 750 | 8200 | 6250 | 2200 | 12000 |

| HDPX 4009/300 | M8976 | 4200 | 9600 | 4800 | 9200 | 300 | 750 | 11200 | 6250 | 2200 | 14000 |

| HDPX 4012/300 | M8977 | 4200 | 12800 | 4800 | 12200 | 300 | 750 | 14200 | 6250 | 2200 | 17000 |

| HDPX 4014/300 | M8978 | 4200 | 14400 | 4800 | 14200 | 300 | 750 | 16200 | 6250 | 2200 | 19000 |

The Table Size can range from 1500 x 3000mm – 6000 x 36000mm depending on your requirements.

Features

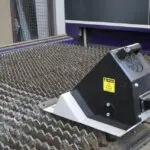

- Hypertherm XPR High Definition Plasma with X Definition Technology

- Hypertherm Core gas console

- Hypertherm torch height control and cutting torch

- Hypertherm Windows based EDGE Connect CNC control and ProNest software

- Virtually dross free finish typically removing the requirement for a secondary cleaning operation

- Maximised productivity and minimised operating costs

- Extremely heavy steel frame designed to withstand constant high speed production

- Bridge carrier design highly resistant to distortion suitable for multi plasma heads and oxy fuel cutting heads and allowing for precision positioning on bed lengths of up to 60 metres

- X and Y axis travel on precision linear guide rails with synchronised servo drives

- Fast positioning speed of 30 m/min with positioning accuracy to 0.05mm

- Arc voltage feedback to control optimum torch height position

- Mechanical and electronic collision avoidance system

- Marking and cutting of material performed with the same plasma torch

Options

- Single station drilling head (requires EDGE Pro control)

- Three station drilling head (requires EDGE Pro control)

- Additional plasma systems (maximum 4 units)

- Six station drilling head (requires EDGE Pro control)

- Bevel cutting plasma head (increases bed width by 500mm. Requires EDGE Pro control)

- CNC tube plasma attachment (requires EDGE Pro control)

- Upgrade to Hypertherm EDGE Pro CNC control

- High efficiency extraction/filtration unit

- Auto nesting software

Morgan Rushworth HDPX Range of High-Definition CNC Metal Cutting Plasma

The Morgan Rushworth HDPX High-Definition CNC Plasma Machine represents the pinnacle of cutting technology, offering unparalleled precision, efficiency, and versatility. As the flagship model in the Morgan Rushworth range, the HDPX is designed to meet the most demanding cutting requirements across a variety of industries. With a robust construction and advanced features, this machine sets a new benchmark for performance and reliability.

Versatile Bed Sizes and Configurations

One of the standout features of the HDPX range is its availability in a wide array of bed sizes. This flexibility ensures that businesses can select a model that perfectly suits their operational needs. From compact setups for smaller workshops to expansive beds for large-scale manufacturing, the HDPX accommodates a diverse range of applications. The design also supports the addition of custom configurations, providing tailored solutions for unique cutting requirements.

Innovative Bridge Carrier Design

The HDPX machine’s special bridge carrier design is engineered for precision and durability. This innovative feature ensures:

- Accurate cutting: Maintains precision even on extremely long bed models, making it ideal for large-scale projects.

- Reduced vibration: Enhances cutting quality by minimising movement during operation.

- Stability under load: Supports the integration of additional equipment without compromising performance.

This advanced design ensures that the HDPX remains a reliable choice for businesses requiring consistent and accurate results.

Advanced Cutting Capabilities

The HDPX High-Definition CNC Plasma Machine is equipped to handle a variety of cutting tasks with ease. Key features include:

- Extra plasma torches: Optional additional torches can be installed to increase productivity, enabling multiple cuts to be made simultaneously.

- Oxy torch units: Single or multiple oxy torches can be added, allowing the machine to cut materials up to 300mm thick.

- High-definition plasma cutting: Delivers clean, precise edges on mild steel, stainless steel, and aluminium.

These capabilities make the HDPX a versatile solution for businesses working with a range of materials and thicknesses.

User-Friendly CNC Control System

The HDPX range is equipped with an advanced CNC control system that simplifies operation and enhances productivity. Features include:

- Intuitive interface: Easy-to-use controls reduce operator training time and streamline workflows.

- File compatibility: Supports DXF and DWG files, enabling seamless integration with design software.

- Real-time visualisation: Operators can preview and adjust cutting paths directly on the LCD screen.

This user-friendly system ensures that even complex cutting tasks can be performed efficiently and accurately.

Built for Efficiency and Durability

The HDPX is designed to deliver exceptional performance in demanding environments. Key aspects of its construction include:

- Heavy-duty frame: Ensures stability and longevity, even under continuous operation.

- High-quality components: Minimises downtime and reduces maintenance requirements.

- Energy-efficient design: Optimises power consumption, reducing operational costs.

These features make the HDPX a cost-effective investment for businesses seeking long-term reliability and performance.

Optional Features and Customisation

To meet specific operational needs, the HDPX range offers a variety of optional features and upgrades, including:

- Dust extraction systems: Maintain a clean and safe working environment by effectively removing fumes and particulates.

- Bevel cutting: Allows for the creation of angled edges, ideal for weld preparation and specialised applications.

- Integrated nesting software: Maximises material utilisation and reduces waste by optimising part layouts.

These options ensure that the HDPX can be tailored to meet the unique demands of any business.

Applications Across Industries

The versatility of the HDPX range makes it suitable for a wide variety of industries, including:

- Construction: Cutting structural steel components and large-scale frameworks.

- Fabrication: Producing custom parts and assemblies with precision.

- Shipbuilding: Creating complex profiles for marine applications.

- Automotive: Manufacturing high-quality components for vehicles and machinery.

Its adaptability ensures that the HDPX can handle both standard and specialised cutting tasks with ease.

Maximising Productivity and ROI

By combining high-speed cutting with precision and reliability, the HDPX delivers significant productivity gains. Its robust design and advanced features reduce downtime and maintenance costs, ensuring a strong return on investment. Additionally, the optional extra torches and oxy cutting capabilities enhance throughput, making it an invaluable asset for businesses aiming to optimise their operations.

Conclusion

The Morgan Rushworth HDPX High-Definition CNC Plasma Machine is a cutting-edge solution that redefines what’s possible in metal cutting. With its innovative design, advanced capabilities, and user-friendly operation, it offers unmatched performance for businesses of all sizes. Whether you’re cutting thin sheet metal or thick steel plates, the HDPX delivers consistent, high-quality results that meet the demands of modern industry.

Invest in the Morgan Rushworth HDPX range to experience the next level of precision, efficiency, and versatility in CNC plasma cutting.