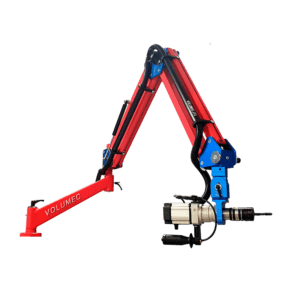

Meyer GT Hydraulic Series Tapping Machine

The Meyer GT Hydraulic Series includes the GT 16H, 24H, and 36H Tapping Machines, offering a tapping capacity range of M5 to M36. Featuring an arm structure with a radius of up to 2050mm, these machines provide an extensive working area, ensuring versatility and adaptability for various tasks.

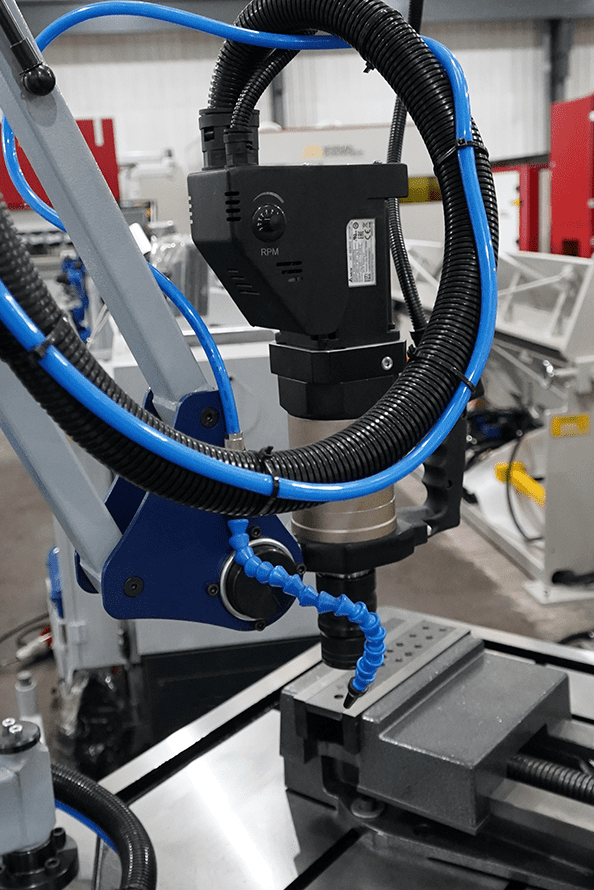

With spinning heads for horizontal and vertical tapping, the GT models include piston hardness adjustment, allowing users to customise the arm’s hardness or softness as required. Safe tap holders prevent tap breakage, delivering maximum efficiency and reliability at high rpm, ensuring swift and effective operations.

| MODEL | GT16H | GT24H | GT36H | |

| Tapping Capacity in steel (Metric) | M | M5 – M16 | M5 – M24 | M5 – M36 |

| Speed | RPM | 0 – 600 | 1st Stage – 0 – 600 2nd Stage 0 – 150 |

0 – 125 |

| Working Area Radius | mm | 2050 | 2050 | 2050 |

| Power | kW | 3 | 3 | 5.5 |

| Arm Operating Measurements (mm) | A | 2050 | 2050 | 2050 |

| B | 1000 | 920 | 920 | |

| C | 600 | 700 | 700 | |

| D | 500 | 500 | 500 | |

| Operating Pressure | bar | 60 – 100 | 60 – 100 | 60 – 120 |

| Weight | kg | 250 | 260 | 270 |

Features

- High speed hydraulic tapping

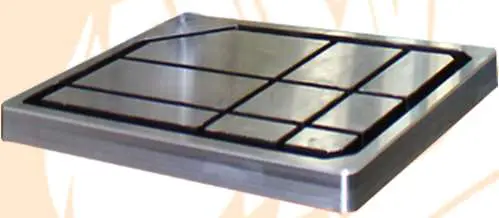

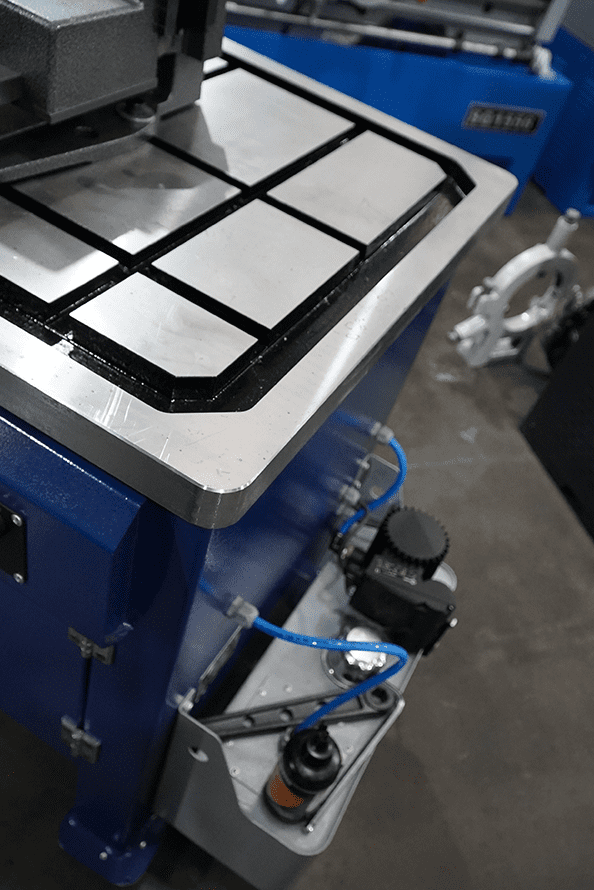

- Heavy construction with integrated table and base

- Articulated tapping arm with adjustable balancing

- Vertical or horizontal tapping

- Tee slot table design

- Variable tapping speed

- Coolant system

- Quick release tapping collet chuck with clutch

- Set of tapping collets (M5, M6, M8, M10, M12, M16, M18, M20, M22, M24, M27, M30, M33, M36 – up to max capacity)

- Integrated collet storage

- Heavy duty castors for easy manoeuvrability

Options

- PLC Control with 100 Programmes

- Digital Read out for Tapping Speed

- Tapping Depth Detection

Meyer GT Hydraulic Series Tapping Machines

The Meyer GT Hydraulic Series, comprising the GT 16H, 24H, and 36H models, is designed to deliver exceptional performance and versatility for a range of tapping applications. With a tapping capacity spanning from M5 to M36, these machines are equipped to handle various tasks in both small-scale workshops and large industrial settings. The innovative design features ensure precision, efficiency, and reliability, making them a valuable asset for modern machining needs.

Extensive Working Area

One of the standout features of the Meyer GT Hydraulic Series is its arm structure, which provides a working radius of up to 2050mm. This extensive range allows operators to work on larger components or reach areas that would otherwise be challenging with conventional tapping machines. The ergonomic arm design ensures smooth and effortless movement, reducing operator fatigue and enhancing productivity.

Horizontal and Vertical Tapping Capabilities

The spinning heads of the GT 16H, 24H, and 36H models enable both horizontal and vertical tapping, adding a layer of versatility to these machines. This dual functionality is particularly useful for complex machining tasks that require precision from multiple angles. The ability to switch between horizontal and vertical orientations ensures adaptability for a wide variety of projects, from simple tapping to intricate threading operations.

Piston Hardness Adjustment

The Meyer GT models are equipped with a piston hardness adjustment feature, allowing users to customise the hardness or softness of the acrobatic arm to suit their specific needs. This adaptability enhances the machine’s performance, enabling precise control over tapping operations. Whether working with delicate materials or handling more robust components, the piston hardness adjustment ensures optimal results.

Safe Tap Holders for Enhanced Efficiency

Tap breakage is a common concern in tapping operations, but the Meyer GT Hydraulic Series addresses this with its safe tap holders. These holders are designed to minimise the risk of tap breakage, even during high-speed operations. By securely holding the taps, they ensure consistent performance and reduce downtime caused by broken tools. Operators can achieve maximum efficiency at high rpm, completing tasks in minimal time without compromising on quality.

Applications Across Industries

The Meyer GT Hydraulic Series is suitable for a wide range of industries, including automotive, aerospace, and general engineering. Its extensive working radius and horizontal and vertical tapping capabilities make it ideal for machining larger components, while the precision and reliability of its features ensure consistent results across various materials and applications. From threading bolts to intricate component assembly, the Meyer GT series delivers outstanding performance.

Key Features of the Meyer GT Hydraulic Series

- Tapping Capacity: Supports M5 to M36 tapping operations.

- Working Radius: Arm structure extends up to 2050mm for extensive coverage.

- Spinning Heads: Enables both horizontal and vertical tapping.

- Piston Hardness Adjustment: Customisable arm hardness for precise control.

- Safe Tap Holders: Reduces the risk of tap breakage and maximises efficiency.

- High RPM Performance: Delivers swift and effective operations.

- Ergonomic Design: Minimises operator fatigue and ensures ease of use.

Durable Construction and Reliable Performance

The Meyer GT Hydraulic Series is built with durability in mind, ensuring consistent performance even under demanding conditions. The robust construction of these machines reduces maintenance requirements, making them a cost-effective solution for long-term use. The powerful hydraulic system ensures smooth and reliable operation, allowing operators to tackle even the most challenging tasks with confidence.

Benefits for Modern Workshops

Investing in the Meyer GT Hydraulic Series provides workshops with a versatile and reliable tapping solution. The combination of advanced features, extensive working radius, and horizontal and vertical tapping capabilities ensures that these machines can handle a diverse range of tasks. Their user-friendly design and safety features make them accessible to operators of all skill levels, enhancing overall productivity.

Conclusion

The Meyer GT Hydraulic Series Tapping Machines are a testament to precision engineering and innovative design. With their extensive working radius, horizontal and vertical tapping functionality, and advanced features such as piston hardness adjustment and safe tap holders, they offer an unparalleled solution for modern machining needs. Whether you’re working on delicate materials or tackling heavy-duty tasks, the Meyer GT series provides the versatility, efficiency, and reliability required to achieve exceptional results. Upgrade your workshop with the Meyer GT Hydraulic Series and experience the difference in performance and productivity.