Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw

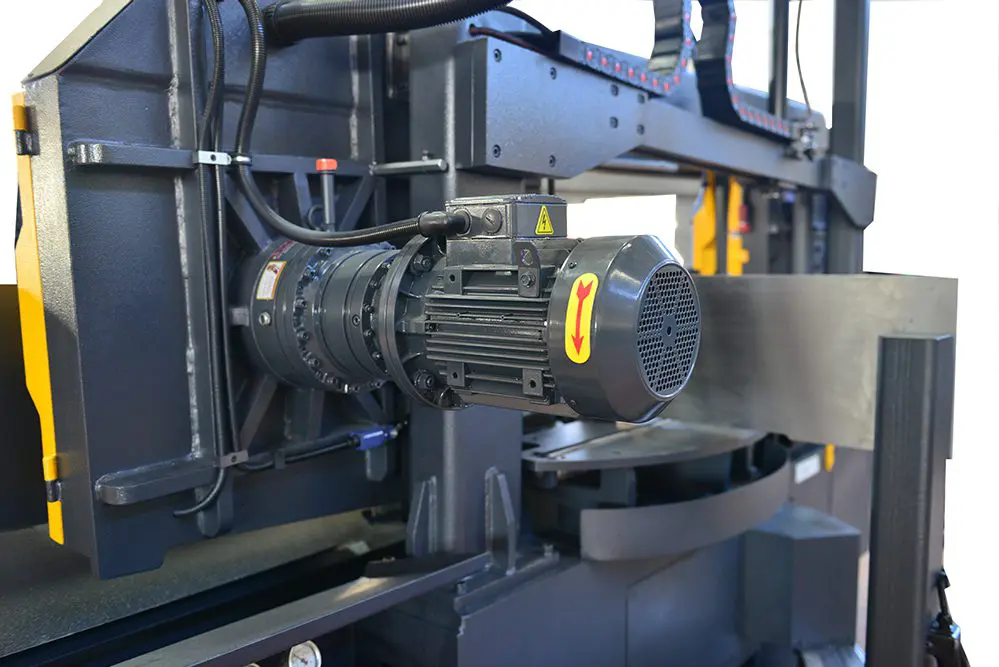

The Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw is a precision-engineered solution designed for flawless cutting performance. Featuring twin-column construction and CNC vice feed automation, this bandsaw offers unmatched accuracy for both small and large sections. Its double mitre capability allows precise automatic mitre cutting, making it ideal for production environments.

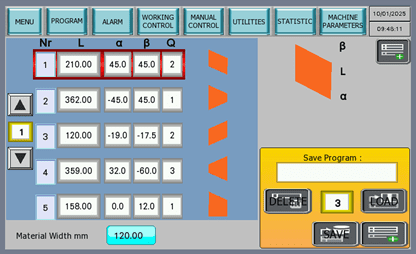

With a touchscreen CNC control, the DGAS manages the entire cutting process, ensuring extreme accuracy in both angle and length. Programmable offline to eliminate operator error, its servo drive system reduces cutting tolerances to near-zero. Perfect for mass production, the DGAS excels in bundle cutting solid materials, tubes, and profiles.

| MODEL | STC440 DGAS CNC | ||||||

| Capacity | 0° | +30° | +45° | +60° | -30° | -45° | |

| ◯ Round | mm | 440 | 440 | 440 | 325 | 440 | 425 |

| □ Flat | mm | 440 | 440 | 440 | 325 | 440 | 425 |

| ▭ Square | mm | 640 x 440 | 605 x 440 | 495 x 440 | 325 x 440 | 545 x 440 | 425 x 440 |

| Bed Height | 855 | ||||||

| Main Drive Motor | kW | 4 | |||||

| Hydraulic Motor | kW | 1.1 | |||||

| Cutting Speeds | m/min. | 20 – 100 | |||||

| Band Dimensions | mm | 6,000 x 41 x 1.3 | |||||

| Tolerances | mm | 0.1 | |||||

| PLC Controller | Omron (Save up to 30 Programs – 10 Steps per program) | ||||||

| Program | CNC Touchscreen for precise programming | ||||||

| Stroke Length | mm | 2,500mm | 2,000mm | ||||

| Remnant Piece (Scrap Length) | mm | 290 (Automatic Mode) 55 (Manual Mode) | |||||

| Max. Feeding | mm | 6,000 | |||||

| Length | mm | 3,150 | 3,150 | ||||

| Width | mm | 4,200 | 3,750 | ||||

| Height | mm | 2,200 | 2,200 | ||||

| Weight | kg | 2,000 | 2,000 | ||||

| Operation | Automatic | ||||||

| Vice | Hydraulic | ||||||

| Vice Feed | Hydraulic | ||||||

Features

- Heavy duty CNC automatic double mitring vice feed bandsaw system allowing repeat accurate cutting of mitred profiles

- Dual feeding system, automatically selected by the machine based on your cutting length

- 2,500mm stroke feeding system

- Offline programming capability

- CNC Touchscreen control (Save up to 30 Programs – 10 Steps per program)

- Powered double mitre Particularly suited for h-beam and hollow section materials

- Variable blade speed allowing full spectrum of materials to be cut

- Extremely accurate up to 0.01mm servo index vice feeding system

- Exceptionally heavy-duty with dual linear guidance

Options

- 3m Length of outfeed Free Running Roller Conveyor

- 3m Length of infeed Free Running Roller Conveyor

- Spray Mist Micro Coolant System (requires an air supply)

- Laser Line illumination of cut line

- Hydraulic Top Bundling Clamp

- Chip Conveyor

Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw: Precision Redefined

The Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw delivers unparalleled cutting precision and efficiency, making it an industry-leading choice for automatic mitre cutting. Designed for both small and large sections, this advanced machine combines twin-column construction with cutting-edge CNC automation to provide an exceptional cutting solution for production environments.

With features such as a touchscreen CNC control, double mitre capability, and servo drive system, the DGAS ensures extreme accuracy and versatility. Its ability to handle mass production and bundle cutting of solid materials, tubes, and profiles makes it indispensable for industries requiring precision and efficiency.

Twin-Column Design for Superior Stability

The twin-column construction of the STC 440 DGAS bandsaw provides maximum stability during operation, ensuring consistent and precise cuts. This design minimises vibration, even when cutting large or heavy materials, delivering clean, straight edges with minimal effort. The rigid frame supports the machine’s advanced features, enabling it to handle demanding cutting tasks with ease.

The twin-column design is particularly suited for high-volume production environments where stability and reliability are paramount. Whether working with solid materials, tubes, or profiles, the STC 440 DGAS ensures flawless performance every time.

Double Mitre Capability for Versatile Cuts

A standout feature of the STC 440 DGAS is its double mitre capability, allowing for automatic mitre cutting in both directions. This capability eliminates the need to manually reposition materials, saving time and ensuring consistent accuracy. Operators can achieve precise angle cuts for a wide variety of applications, making this bandsaw an ideal choice for industries such as fabrication, construction, and engineering.

With the ability to handle both simple and complex mitre cuts, the DGAS offers unmatched versatility and reliability, even in the most challenging cutting scenarios.

CNC Automation for Extreme Accuracy

The touchscreen CNC control sets the STC 440 DGAS apart from traditional bandsaws. This advanced control system manages the cutting process from start to finish, dictating both the angle and length of each cut with exceptional precision. The CNC system can be programmed offline, eliminating the risk of operator error and ensuring consistent results.

By automating the cutting cycle, the DGAS improves efficiency and reduces waste, making it an essential tool for businesses focused on high-precision production. The servo drive system further enhances accuracy by reducing cutting tolerances to near-zero, delivering results that are as close to flawless as possible.

Ideal for Mass Production and Bundle Cutting

The Sterling STC 440 DGAS is specifically designed for mass production and bundle cutting, making it an excellent choice for high-demand workshops and industrial environments. Its ability to cut multiple pieces simultaneously improves productivity and ensures consistent results, even when working with large volumes of material.

Whether you’re cutting solid materials, tubes, or profiles, the DGAS delivers efficiency and precision, ensuring your operation runs smoothly and cost-effectively.

Key Features of the Sterling STC 440 DGAS

The Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw comes equipped with a range of features that enhance its performance and usability:

- Twin-Column Design: Provides maximum stability and reduces vibration for precise cuts.

- Double Mitre Capability: Enables automatic mitre cutting in both directions without manual adjustments.

- CNC Touchscreen Control: Fully automates the cutting process, managing angles and lengths with extreme accuracy.

- Offline Programming: Allows pre-programmed cuts to eliminate operator error and improve efficiency.

- Servo Drive System: Reduces cutting tolerances to near-zero for flawless results.

- High Cutting Capacity: Handles solid materials, tubes, and profiles with ease, even in large bundles.

Applications Across Industries

The versatility of the STC 440 DGAS makes it suitable for a wide range of industries, including:

- Fabrication: Ideal for cutting structural components with precision.

- Construction: Handles large materials and complex mitre cuts for construction projects.

- Engineering: Perfect for producing accurate parts for machinery and assemblies.

- Metalworking: Excels in high-volume production of tubes, profiles, and solid materials.

With its robust construction and advanced features, the STC 440 DGAS is a reliable solution for industries that demand precision and efficiency.

Durability and Low Maintenance

Built with high-quality materials and precision engineering, the Sterling STC 440 DGAS is designed for long-term reliability. Its servo drive system and CNC automation minimise wear and tear, while its rigid twin-column frame ensures consistent performance over time.

The machine’s user-friendly design also makes maintenance straightforward, reducing downtime and keeping productivity high. For workshops seeking a durable and efficient cutting solution, the STC 440 DGAS is an excellent investment.

Summary: Sterling STC 440 DGAS

The Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw is a powerful, precise, and efficient cutting solution designed for demanding industrial applications. With features like double mitre capability, twin-column stability, and CNC touchscreen automation, this bandsaw offers extreme accuracy and versatility.

Ideal for mass production and bundle cutting, the DGAS delivers consistent results for solid materials, tubes, and profiles. Its ability to be programmed offline eliminates operator error, while the servo drive system ensures cutting tolerances are reduced to near-zero. Perfect for industries such as fabrication, construction, and engineering, the DGAS sets a new standard for precision and efficiency.

Why Choose the Sterling STC 440 DGAS?

The Sterling STC 440 DGAS is a reliable, high-performance bandsaw that combines advanced automation with robust construction. Its double mitre capability, CNC control, and offline programming make it a versatile and cost-effective choice for workshops and industrial environments.

For businesses focused on precision, efficiency, and durability, the Sterling STC 440 DGAS CNC Twin-Column Automatic Bandsaw is the ultimate solution. Experience flawless cutting and unmatched performance with Sterling.