Sterling STC SA Twin Column Semi-Automatic Bandsaw 415V

The Sterling STC SA range features a highly rigid, twin-column format for maximum stability – perfectly suited for cutting through large, heavy, thick materials. With a maximum cutting diameter of 1300 x 1300mm, the range has a vast capacity, accompanied with a wide selection of features.

Sterling’s range of bandsaws are one of the leading brands in the metal cutting world. Reliability, dependability and high accuracy are hallmarks of Sterling bandsaws with the Sterling STC SA twin column, semi automatic, single mitre bandsaw being no exception.

| MODEL | STC330 SA | STC360 SA | STC460 SA | STC560 SA | STC810 SA | STC825 SA | STC1020 SA | STC1110 SA | STC1313 SA | ||||||||

| STOCKCODE | 15163 | 15156 | 15157 | 15158 | 15164 | 15166 | 15187 | 15165 | 15271 | ||||||||

| Capacity | 90° | 45° | 90° | 45° | 90° | 45° | 90° | 45° | 90° | 45° | 90° | 45° | 90° | 45° | 90° | 90° | |

| ◯ Round | mm | 330 | 300 | 380 | 300 | 460 | 380 | 560 | 410 | 810 | 480 | 825 | 480 | 1020 | 675 | 1110 | 1300 |

| □ Square | mm | 330 | 300 | 380 | 300 | 460 | 380 | 560 | 410 | 810 | 480 | 790 | 480 | 1020 | 675 | 1110 | 1300 |

| ▭ Rectangle | mm | 360 x 330 | 300 x 380 | 520 x 380 | 300 x 380 | 650 x 460 | 380 x 460 | 750 x 560 | 410 x 560 | 850 x 810 | 480 x 810 | 950 x 790 | 480 x 790 | 1020 x 1020 | 675 x 1020 | 1110 x 1110 | 1300 x 1300 |

| Bed Height | mm | 635 | 590 | 590 | 590 | 585 | 585 | 595 | 545 | 545 | |||||||

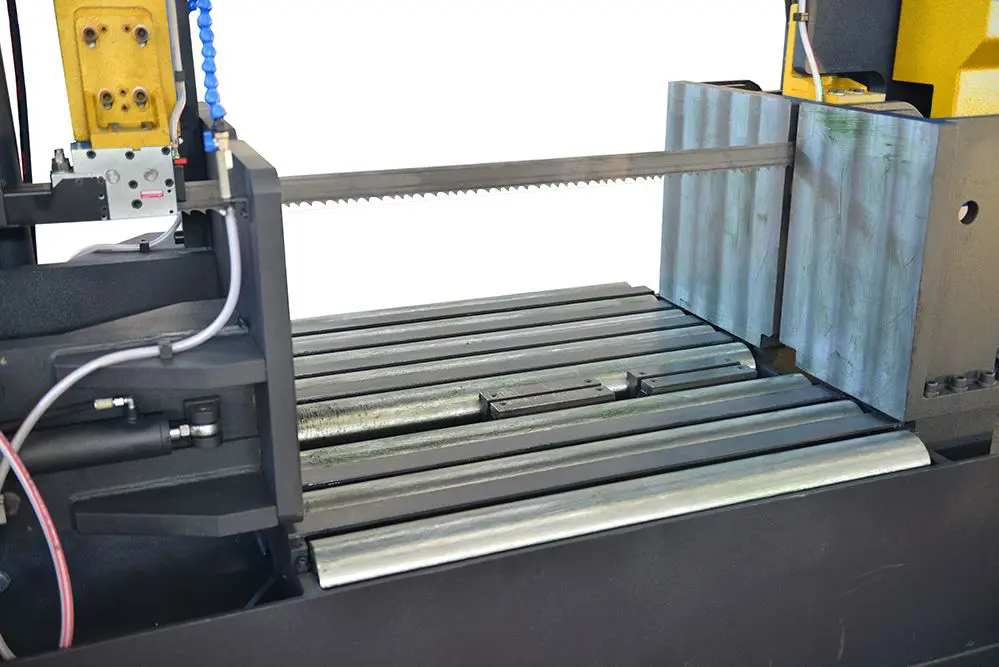

| Blade Size | mm | 5000 x 34 x 1.1 | 4800 x 34 x 1.1 | 5200 x 41 x 1.3 | 6000 x 41 x 1.3 | 8200 x 41 x 1.3 | 8200 x 54 x 1.6 | 9500 x 54 x 1.6 | 10500 x 67 x 1.6 | 12100 x 67 x 1.6 | |||||||

| Cutting Speed | m/min | 20 – 100 | 20 – 100 | 20 – 100 | 20 – 100 | 20 – 100 | 20 – 100 | 20 – 100 | 20 – 100 | 20 – 100 | |||||||

| Motor | Kw | 3 | 3 | 4 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | |||||||

| Length | mm | 2830 | 2850 | 3100 | 3400 | 3900 | 3900 | 4500 | 4800 | 5300 | |||||||

| Width | mm | 920 | 930 | 1000 | 1000 | 1200 | 1200 | 1700 | 1500 | 1500 | |||||||

| Height | mm | 1630 | 1660 | 1800 | 2050 | 2350 | 2350 | 2750 | 2975 | 3175 | |||||||

| Weight | Kg | 1030 | 1330 | 1520 | 2045 | 3080 | 3424 | 6950 | 10440 | 11500 | |||||||

| Operation | Semi-automatic | Semi-automatic | Semi-automatic | Semi-automatic | Semi-automatic | Semi-Automatic | Semi-automatic | Semi-automatic | Semi-automatic | ||||||||

| Vice | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

Features

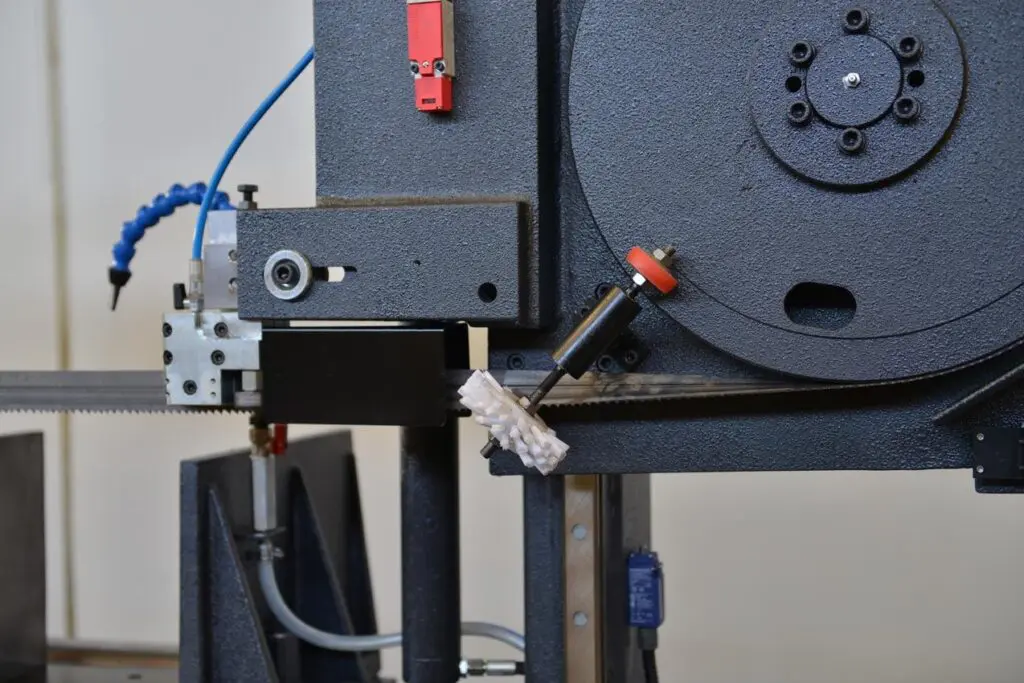

- Twin column rigidity

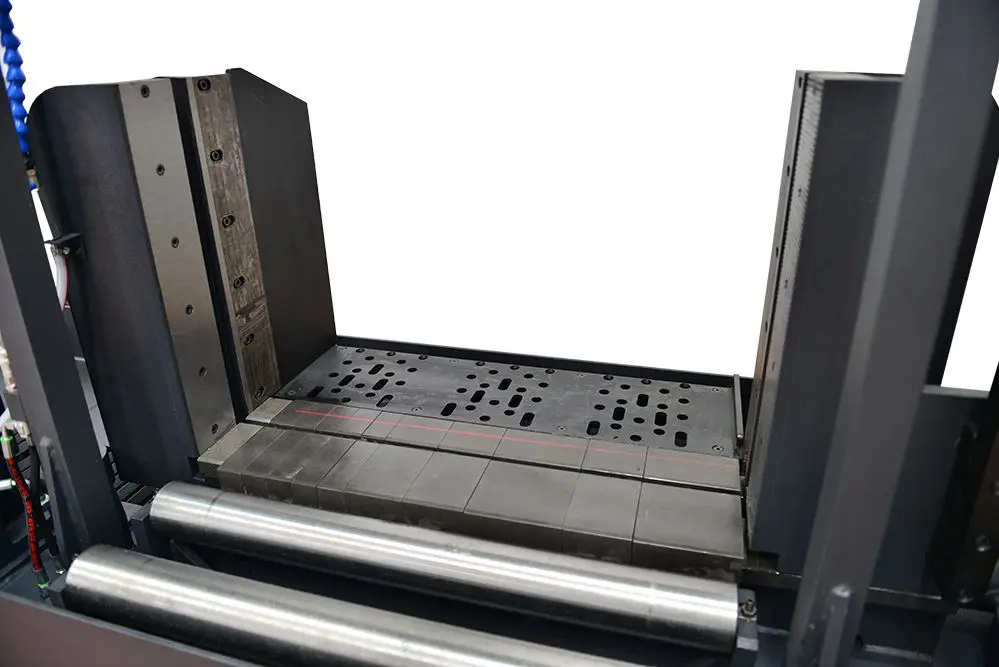

- Linear guidance bearing

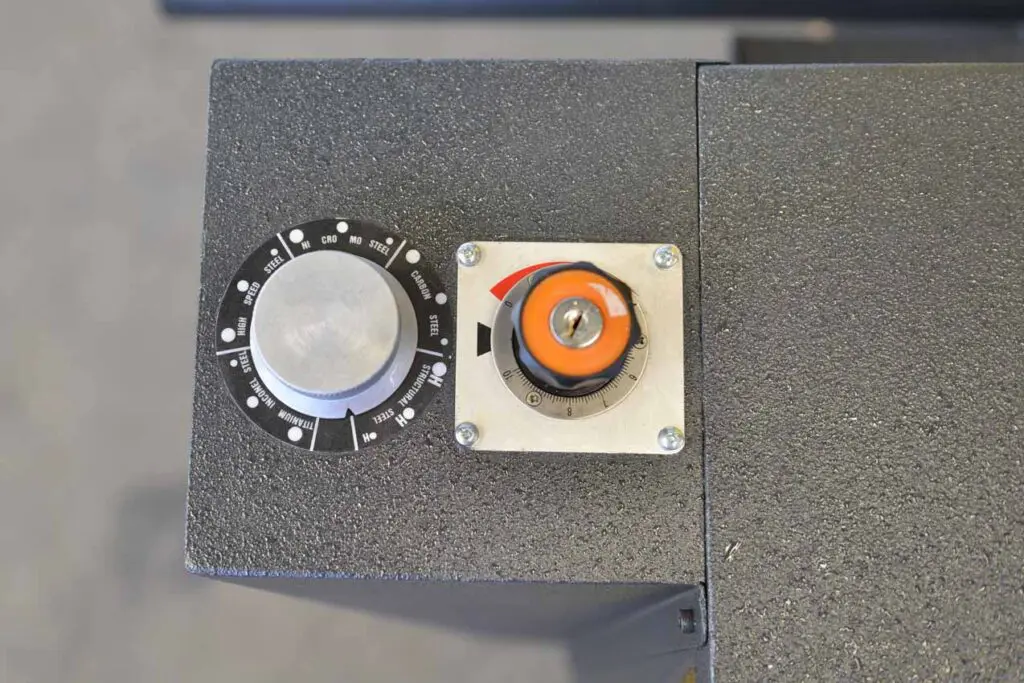

- Inverter drive providing infinitely variable blade speed

- Material limit shaft

- Automatic bow return

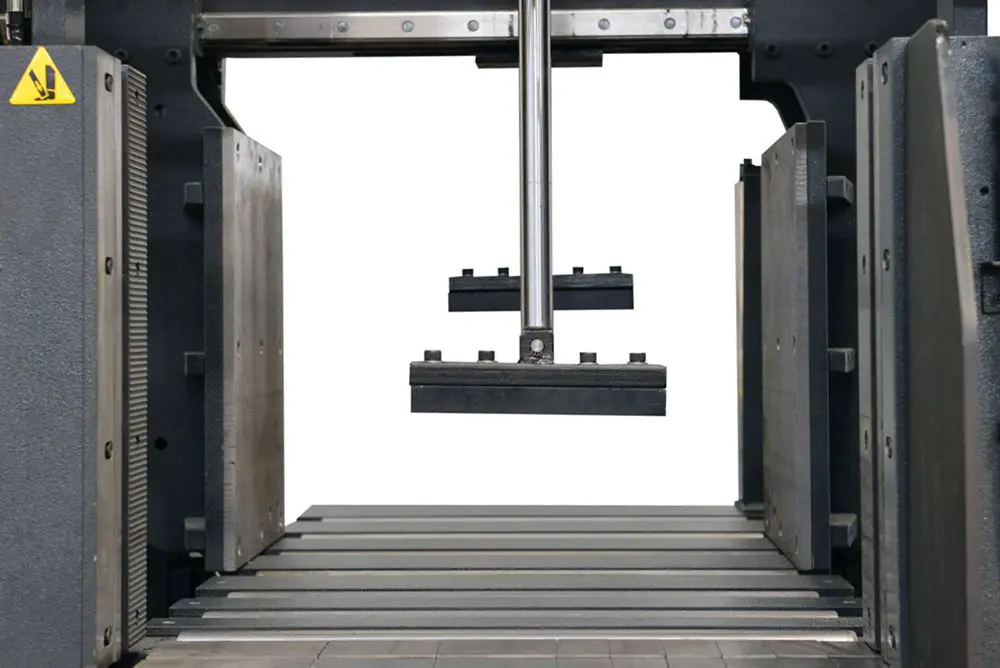

- Hydraulic vice

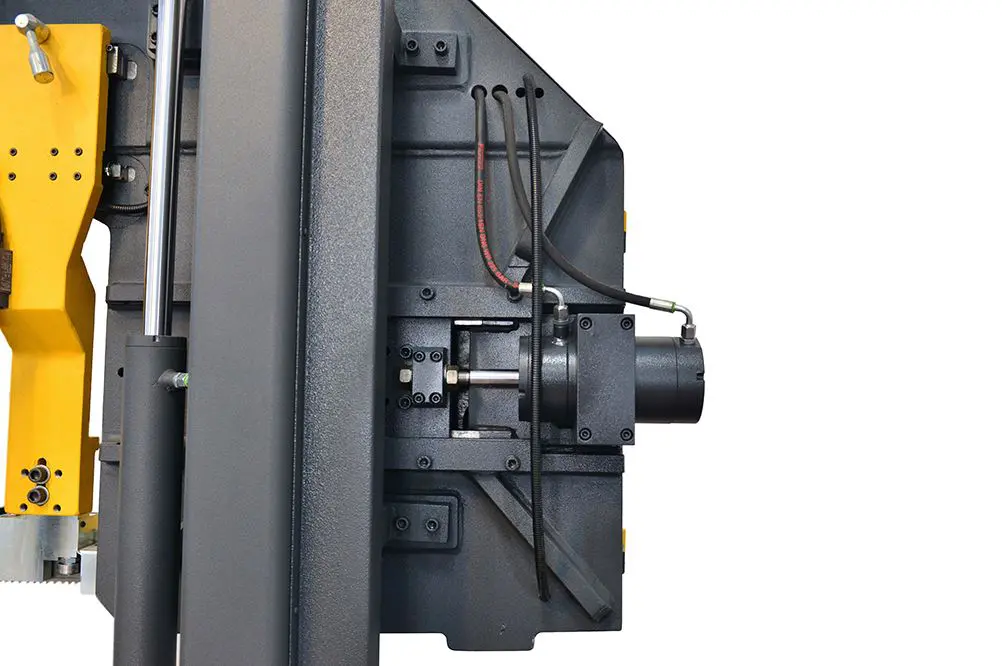

- Hydromechanical Blade Tension indicator (Hydraulic as standard on STC 1020 and above)

- Carbide blade guides

- Flood Coolant system

- Variable Vice Pressure

- Optical Height Adjustment

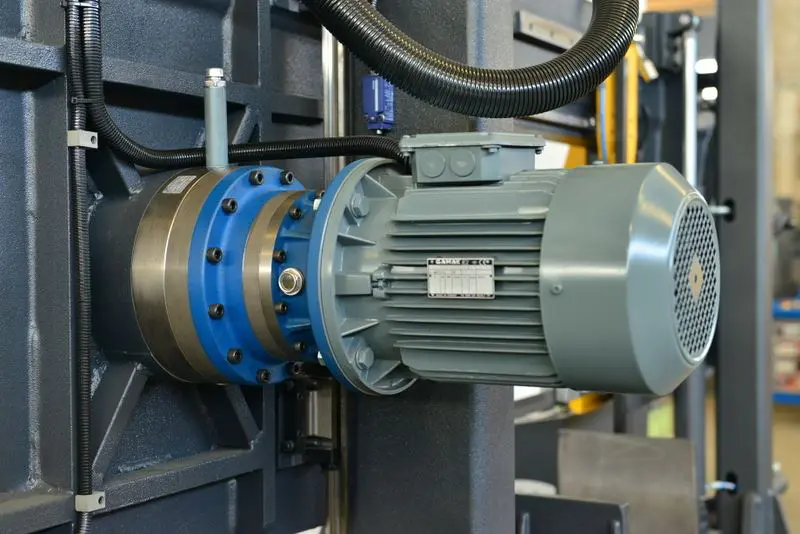

- Heavy Duty Gearbox

- Interlocking Security Switches for CE compliance

- Chip Conveyor (STC1110 SA and STC1313 SA only)

- Synchronisation Moveable Arm / Vice (STC1110 SA and STC1313 SA only)

Options

- Hydraulic blade tension (Standard on STC 1020 and above)

- Hydraulic top clamps

- Chip conveyor (Standard on STC1110 SA and STC1313 SA)

- Spray mist lubrication

- Laser cutting line

- Digital bow return height

- Roller track and measuring systems

- Motorised Roller Track Segments (Infeed or Outfeed)

- High Vice (for increased stability)

- Split Vice (for increased stability)

- Double / Second Vice (for increased stability)

- Hexagonal Vice (for bundles of material)

Sterling STC SA Twin Column Semi-Automatic Bandsaw 415V: Power, Precision, and Performance

The Sterling STC SA Twin Column Semi-Automatic Bandsaw 415V is a heavy-duty cutting solution designed for precision, durability, and stability. Known for their reliability and dependability, Sterling bandsaws are a trusted name in the metal-cutting industry. The STC SA model builds on this legacy, offering a robust twin-column design that delivers maximum stability and accuracy when cutting large, heavy, and thick materials.

With a maximum cutting capacity of 1300 x 1300mm, the Sterling STC SA is engineered for high-performance cutting in demanding industrial environments. This semi-automatic, single mitre bandsaw is the ideal choice for workshops and facilities that require precision and efficiency for large-scale cutting operations.

Twin-Column Design for Unparalleled Stability

At the heart of the Sterling STC SA is its twin-column design, which provides unmatched rigidity and stability during operation. The dual-column structure minimises vibration, ensuring consistent accuracy even when cutting through the toughest materials. This design also enhances the machine’s durability, allowing it to maintain high performance under heavy loads.

The twin-column configuration makes the STC SA especially suited for industries such as construction, fabrication, and engineering, where precise and reliable cuts are essential for large-scale projects.

Exceptional Cutting Capacity

The Sterling STC SA Bandsaw boasts a remarkable cutting capacity of up to 1300 x 1300mm, enabling it to handle some of the largest and thickest materials with ease. Whether you’re working with structural steel, solid blocks, or other heavy-duty materials, this bandsaw is equipped to deliver clean, accurate cuts every time.

The expansive cutting capacity ensures that the STC SA is not only versatile but also highly efficient for high-volume cutting tasks. Its ability to handle large workpieces makes it an invaluable asset in industrial environments.

Semi-Automatic Operation for Efficiency

The semi-automatic functionality of the STC SA simplifies the cutting process, reducing operator effort and increasing productivity. Key features such as auto down-feed and automatic bow return ensure smooth, consistent cutting while minimising manual intervention.

The bow returns to its starting position automatically after each cut, allowing operators to prepare for the next task more quickly. This functionality streamlines workflows, making the STC SA ideal for workshops with high production demands.

Precision Cutting with Single Mitre Capability

The single mitre capability of the Sterling STC SA allows for precise angle cuts, making it a versatile solution for a wide range of applications. The saw can easily handle mitre cuts on large workpieces, eliminating the need for additional adjustments or manual repositioning. This feature is particularly valuable for industries requiring precision angle cuts, such as metal fabrication and custom engineering.

Advanced Features for Optimised Performance

The Sterling STC SA comes equipped with a range of advanced features designed to enhance performance and usability:

- Hydraulic Vice: Ensures secure clamping of materials, reducing movement during cutting for precise results.

- Variable Blade Speeds: Allows operators to optimise cutting conditions for different materials, extending blade life and improving cut quality.

- Coolant System: Integrated coolant delivery minimises heat buildup, ensuring cleaner cuts and reducing blade wear.

- Intuitive Controls: User-friendly controls make it easy to adjust settings and operate the machine efficiently.

These features combine to create a machine that is both powerful and easy to use, making it suitable for a wide range of cutting applications.

Ideal for Industrial Applications

The Sterling STC SA Twin Column Semi-Automatic Bandsaw is specifically designed for industrial environments where reliability, precision, and efficiency are paramount. Applications include:

- Construction Projects: Cutting large steel beams and structural components with accuracy.

- Metal Fabrication: Creating precise cuts for custom parts and assemblies.

- Engineering Workshops: Handling large-scale cutting tasks for complex projects.

Its ability to handle diverse materials and large workpieces makes it a versatile and indispensable tool for demanding industrial operations.

Durable Construction for Long-Term Use

The heavy-duty construction of the Sterling STC SA ensures long-term reliability and performance. Built with high-quality materials and precision engineering, this bandsaw is designed to withstand the rigours of continuous industrial use. Its robust design also minimises maintenance requirements, reducing downtime and operational costs.

Summary: Sterling STC SA Bandsaw

The Sterling STC SA Twin Column Semi-Automatic Bandsaw 415V offers exceptional precision, stability, and cutting capacity for large-scale industrial applications. With a twin-column design, semi-automatic operation, and single mitre capability, this bandsaw delivers unmatched performance for cutting large, heavy, and thick materials.

Equipped with features like variable blade speeds, a hydraulic vice, and an integrated coolant system, the STC SA ensures clean, accurate cuts while maximising efficiency. Its cutting capacity of 1300 x 1300mm makes it ideal for industries such as construction, fabrication, and engineering.

Why Choose the Sterling STC SA Twin Column Bandsaw?

The Sterling STC SA is more than just a bandsaw—it’s a powerful solution for tackling the toughest cutting tasks. Its robust construction, advanced features, and user-friendly design make it an invaluable asset for industrial operations.

For workshops and facilities seeking a dependable, high-capacity bandsaw, the Sterling STC SA Twin Column Semi-Automatic Bandsaw 415V is the ultimate choice. Invest in precision, reliability, and efficiency with Sterling.