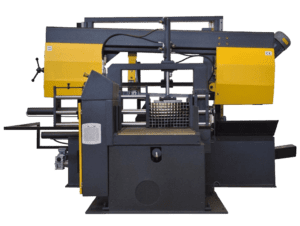

Sterling STC CH Twin-Column Automatic Bandsaw

Sterling’s range of bandsaws are one of the leading brands in the metal cutting world. The Sterling STC CH NC twin-column, automatic, bandsaw being no exception. This a fully automatic machine in a twin-column design ideally suited for cutting solid material, as well as pipes, profiles and beams in steel cutting.

The Siemens PLC controller on this saw enables the user to set-up a programme with 10 steps for automatic cutting, simply punch in your lengths and quantities, and let the saw do the work for you.

| MODEL | STC330 CH NC | STC360 CH NC | STC460 CH NC | STC560 CH NC | |

| Capacity | 0° | 0° | 0° | 0° | |

| ◯ Round | mm | 330 | 360 | 460 | 560 |

| □ Flat | mm | 325 | 360 | 460 | 560 |

| ▭ Square | mm | 350 x 325 | 400 x 360 | 550 x 460 | 600 x 560 |

| Bed Height | 845 | 795 | 805 | 810 | |

| Main Drive Motor | kW | 3 | 3 | 4 | 5.5 |

| Cutting Speeds | m/min. | 20 – 100 | |||

| Band Dimensions | mm | 5000 x 34 x 1.1 | 4800 x 34 x 1.1 | 5200 x 41 x1.3 | 6000 x 41 x 1.3 |

| Tolerances | mm | 0.3 | |||

| PLC Controller | Siemens | ||||

| Program | 1 Program with 10 Steps | ||||

| Stroke Length | mm | 500 | |||

| Remnant Piece (Scrap Length) | mm | 105 (Automatic Mode) 50 (Manual Mode) | 110 (Automatic Mode) 55 (Manual Mode) | 125 (Automatic Mode) 55 (Manual Mode) | 125 (Automatic Mode) 60 (Manual Mode) |

| Max. Feeding | mm | 6000 | |||

| Length | mm | 2,500 | 2,500 | 3,250 | 4,000 |

| Width | mm | 1,950 | 2,850 | 3,000 | 3,250 |

| Height | mm | 1,750 | 2,000 | 2,100 | 2,200 |

| Weight | kg | 2,150 | 1,890 | 2,100 | 2,350 |

| Operation | Automatic | ||||

| Vice | Hydraulic | ||||

| Vice Feed | Hydraulic | ||||

Features

- Twin column rigidity

- Fully automatic NC

- Hydromechanical Blade Tension

- Inverter drive providing infinitely variable blade speed

- Automatic bow return

- Hydraulic vice (500mm stroke, 6000mm max. feed)

- Hydraulic feeding vice

- Hydraulic rear vice

- Siemens PLC control panel (1 Programme – 10 Steps)

- Sensitive cutting pressure regulation

- Swarf brush

- Carbide blade guides

- Flood Coolant system

Options

- Hydraulic blade tension

- Hydraulic top clamps

- Chip conveyor

- Spray mist lubrication

- Hexagonal Vice for bundle cutting

- Roller track and measuring systems

Transform Your Workshop’s Efficiency with the Sterling STC CH NC Bandsaw

If precision, reliability, and efficiency are what you need, the Sterling STC CH NC Twin-Column Automatic Bandsaw is your ideal solution. A product of the renowned Sterling range, this fully-automatic machine is engineered to handle demanding metal-cutting tasks with ease. Its twin-column design ensures unparalleled stability, making it perfect for cutting solid materials, pipes, profiles, and steel beams.

The Sterling STC CH NC isn’t just a tool—it’s a game-changer for workshops that demand performance without compromise.

Why the Sterling STC CH NC Stands Out

Built for Durability

The robust twin-column construction provides superior rigidity, ensuring precision cuts across a wide variety of materials. Whether you’re cutting round, square, or rectangular sections, this bandsaw guarantees consistent performance, even during high-volume operations.

Advanced Automation

Featuring a Siemens PLC controller, this bandsaw takes automation to the next level. You can program up to 10 steps for automatic cutting—simply input the lengths and quantities, and the machine does the rest. This level of control means less operator intervention, faster production, and fewer errors.

Versatility at Its Core

With its ability to handle a wide range of materials and applications, the Sterling STC CH NC is versatile enough to be the mainstay of any fabrication shop, big or small.

Enhance Your Productivity

In a busy workshop, time is money. The automatic bow return on the Sterling STC CH NC reduces downtime between cuts, allowing for seamless transitions to the next task. Its variable blade speeds ensure optimal performance for both mild and stainless steels, adapting effortlessly to your needs.

The hydraulic gravity down-feed system provides precise control over cutting speed, matching the material being processed. This feature not only enhances accuracy but also prolongs blade life, reducing maintenance costs and boosting productivity.

The Importance of Cooling and Safety

Flood Coolant System

One of the standout features of the Sterling STC CH NC is its built-in flood coolant system. This system prevents overheating, reduces blade warping, and ensures clean cuts. By extending blade life and improving cut quality, the coolant system helps your workshop stay efficient and productive.

Safety First

Safety is a priority in any workshop, and the automatic stop function on this bandsaw provides peace of mind. Once the cut is complete, the blade automatically stops spinning, reducing the risk of accidents and ensuring safer interactions for your team.

Tailored for UK Fabrication Shops

Fabricators across the UK trust Sterling bandsaws for their reliability and precision. The STC CH NC Bandsaw continues this tradition, offering a perfect blend of cutting-edge technology and robust design. Whether you’re working on structural steel, heavy profiles, or intricate components, this bandsaw delivers exceptional results every time.

Its twin-column design makes it an ideal choice for heavy-duty applications, while its advanced automation ensures it can handle repetitive tasks with ease.

Ready to Go Out of the Box

At Selmach Machinery, we know how important it is to hit the ground running. That’s why every Sterling STC CH NC Bandsaw comes fully equipped with a starter set of our premium Goldcut Blades. Tailored to your specific cutting requirements, these blades ensure optimal performance from the first cut.

We also provide a free container of coolant, so your machine is ready to go as soon as it arrives. This attention to detail allows you to focus on what matters—your work.

Support Beyond the Sale

Your investment in the Sterling STC CH NC Bandsaw is supported by Selmach Machinery’s commitment to excellence. We provide a comprehensive range of blades and coolants, available through our dedicated tooling website, to keep your machine performing at its best.

Need help selecting the right tools for your application? Our team of experts is just a call away, ready to provide advice and support whenever you need it.

Explore the Sterling Range

While the STC CH NC Bandsaw is a remarkable machine, it’s just one part of our extensive range. At Selmach Machinery, we offer a wide variety of Sterling and Bianco bandsaws to meet every cutting need. Whether you’re looking for a compact solution or a heavy-duty workhorse, our selection ensures there’s a machine tailored to your workshop.

Visit our website to explore the full range and find the perfect bandsaw for your operation.

The Selmach Advantage

Expertise You Can Trust

With years of experience serving the UK fabrication industry, Selmach Machinery is a name you can rely on. Our team is dedicated to helping you find the right equipment and providing ongoing support to ensure your success.

Customer-Centric Approach

We’re not just about selling machines—we’re about building relationships. From your first enquiry to after-sales support, we’re here to help every step of the way.

Start Cutting with Confidence

The Sterling STC CH NC Twin-Column Automatic Bandsaw offers a powerful combination of advanced automation, robust construction, and user-friendly design. It’s more than just a bandsaw—it’s a partner that helps you work smarter, faster, and safer.

Ready to elevate your workshop’s capabilities? Contact us today to learn more about the Sterling STC CH NC or explore our full range of cutting solutions. Let Selmach Machinery help you achieve new levels of precision and efficiency.