Sterling SAR400 Aluminium Circular Saw

The Sterling SAR range of circular saws are designed for working with aluminium sections and extrusions. All models feature high blade speeds and are pull down operated. These models are offered with either manual or pneumatic clamping.

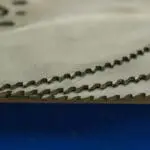

These machines use TCT toothed cutting blades which are available in a range of tooth pitches depending on the material section and required finish.

We recommend that all Aluminium saws are used with an extraction system, to reduce the risk of dust related accidents and explosions.

| MODEL | SAR 400 | SAR 400P | |||||

| Capacity | 90° | 45° L + R | 90° | 45° L + R | |||

| ◯ Tube | mm | 140 | 130 | 140 | 130 | ||

| □ Box Section | mm | 120 | 100 | 110 | 100 | ||

| ▭ Widest Cut | mm | 215 x 100 | 150 x 100 | 215 x 100 | 150 x 100 | ||

| Blade Size | mm | 400ø x 32 bore | 400ø x 32 bore | ||||

| Blade Speed | rpm | 3000 | 3000 | ||||

| Motor | Kw | 1.5 | 1.5 | ||||

| Length | mm | 730 | 730 | ||||

| Width | mm | 810 | 810 | ||||

| Height | mm | 1400 | 1400 | ||||

| Weight | Kg | 130 | 180 | ||||

| Operation | Instant Pull Down | Instant Pull Down | |||||

| Vice | Manual | Pneumatic | |||||

Features

- Heavy duty

- Fast aluminium cutting

- Large capacity

- Mitring head 45° left and right

- Flat solid bed

- Material length stop

- Bar support roller

- Mitre left and right 0, 15, 22.5, 30 and 45 degree mitre stops

- 2 x Pneumatic vertical and horizontal clamps

- Safety cutting with full blade guard

- 1 x Roller conveyor (2m right) on pneumatic models

Options

- Base – stock code 15012

- Measuring conveyor right side 3, 4, 5 or 6m

- Roller conveyor left side 3, 4, 5 or 6m

- Cooling system for cutting aluminium

- Hydro-check for cutting aluminium profiles (hydraulic speed setting)

- Auto slicing feature (90° only)

- Automatic measurement converyor

Sterling SAR Range of Circular Saws – Precision Cutting for Aluminium Sections

The Sterling SAR range of circular saws is engineered for high-performance cutting of aluminium sections and extrusions. Designed to deliver smooth, accurate, and efficient cutting, these saws are the ideal solution for fabricators, manufacturers, and metalworking professionals who require precision when working with aluminium.

With a combination of high blade speeds, pull-down operation, and manual or pneumatic clamping options, the SAR series is versatile and adaptable to different production environments. Whether used for single cuts or batch production, these saws ensure consistency and reliability in every application.

Key Features of the Sterling SAR Circular Saws

High Blade Speeds for Clean, Precise Cuts

One of the standout features of the Sterling SAR range is its high blade speed, which is crucial when cutting aluminium. The increased cutting speed ensures a smooth finish with minimal burring, reducing the need for secondary finishing processes such as deburring or polishing. This efficiency is particularly beneficial for industries requiring high-quality edge finishes, such as architectural fabrication, automotive production, and aerospace manufacturing.

Pull-Down Operation for Easy Handling

The pull-down operation of these saws allows for smooth, controlled cutting, ensuring that operators can achieve precise results with minimal effort. This design enhances both accuracy and safety, providing a controlled descent of the cutting blade through the material. The ergonomic design also reduces operator fatigue, making it a practical choice for environments where repetitive cutting is required.

For further ease of handling, you can pair our circular saws with a vast range of Roller Track and Measuring Systems for increased ergonomics and efficiency.

Manual or Pneumatic Clamping Options

The Sterling SAR series offers both manual and pneumatic clamping options, allowing users to choose the best system for their specific needs:

- Manual clamping is a simple, cost-effective solution for workshops with lower production volumes or more varied cutting requirements.

- Pneumatic clamping is ideal for higher-volume production settings, reducing operator workload and ensuring consistent pressure on the material, which results in greater precision and repeatability.

Advanced Cutting Technology – TCT Blades for Maximum Performance

TCT Toothed Cutting Blades

Each machine in the Sterling SAR range is equipped with Tungsten Carbide Tipped (TCT) blades, ensuring long-lasting durability and superior cutting performance. TCT blades are designed to withstand the high-speed cutting of aluminium without excessive wear, making them ideal for both light and heavy-duty applications.

Customisable Tooth Pitch for Different Applications

The tooth pitch of the TCT cutting blades can be tailored to the specific material section and required finish, allowing for greater flexibility in different cutting applications.

- Fine tooth pitch: Ideal for thin-walled extrusions, providing a smooth, burr-free finish.

- Coarse tooth pitch: Suitable for thicker aluminium sections, ensuring fast and efficient material removal while maintaining quality.

Find out more about our range of Circular Saw Blades here.

Versatility in Application – Ideal for Aluminium Fabrication

The Sterling SAR circular saws are widely used across various industries that require precise and efficient aluminium cutting:

Architectural and Structural Aluminium Fabrication

In construction and architectural fabrication, aluminium sections are commonly used for window frames, doors, curtain walling, and façade systems. The high-speed cutting capability of the SAR range ensures that these components can be cut quickly, accurately, and with minimal finishing required.

Automotive and Aerospace Manufacturing

The automotive and aerospace sectors demand high precision and repeatability when cutting aluminium components for vehicle frames, body panels, and structural supports. The SAR range’s ability to handle thin and thick sections with equal precision makes it a valuable asset in these industries.

General Metalworking and Fabrication

For metal fabrication shops, the SAR range offers a reliable and user-friendly solution for cutting aluminium profiles, tubes, and solid sections. The versatility of blade tooth pitches allows fabricators to achieve the desired finish on a variety of materials and thicknesses.

Efficiency and Productivity – Designed for Industrial Use

Minimal Maintenance and Long Blade Life

The TCT cutting blades used in the Sterling SAR saws are built to last longer than standard steel blades, reducing the need for frequent blade changes and maintenance. This extends the lifespan of the saw while minimising downtime in busy production environments.

Operator Safety and Comfort

- Stable cutting operation ensures operator safety, reducing the risk of material slippage during cutting.

- Ergonomic pull-down handle allows for comfortable use, even during long cutting sessions.

- Optional extraction systems help reduce dust and debris, maintaining a clean working environment.

Choosing the Right Model – Meeting Your Cutting Requirements

The Sterling range includes several models to accommodate different cutting capacities, production volumes, and workshop requirements. When selecting the right model, consider the following:

- Material size and thickness – Choose a model with the appropriate cutting capacity.

- Production volume – For higher output, pneumatic clamping can enhance efficiency.

- Required finish quality – Selecting the right blade tooth pitch ensures the best results for your specific application.

Conclusion – Why Choose the Sterling SAR Circular Saw Range?

The Sterling SAR range of circular saws is engineered for precision, efficiency, and durability, making it an ideal choice for cutting aluminium sections and extrusions. With high-speed cutting, pull-down operation, and manual or pneumatic clamping options, these saws provide consistent, high-quality results across various industries.

By integrating TCT cutting blades with adjustable tooth pitch, the SAR range delivers a versatile cutting solution that meets the needs of fabricators, manufacturers, and metalworking professionals. Whether you’re producing architectural frames, automotive components, or custom aluminium fabrications, the Sterling SAR saws offer the performance and reliability needed to enhance productivity and achieve superior cutting quality.

Investing in a Sterling SAR circular saw ensures high efficiency, minimal maintenance, and long-term operational success.