Pehu LMS Automatic Measuring System

The PEHU LMS30 to PEHU LMS80 are powered measuring system models which can be configured as either auto-measuring or auto-feeding systems. The operator enters the required stop positions into the NC control and the system automatically runs through the program until it is completed. Specific systems can be configured to work with saws, drills and steelworkers or punching machines.

The different models are configurable for varied capacities, and levels of automation.

| MODEL | Servo Control | Measuring Operation | Flip-Up Stop Operation | Set-Up | Width | Base Length | Additional Lengths | Positioning Accuracy | Positioning Speed |

| mm | mm | m | mm | m/min | |||||

| PEHU LMS15-04 | N/A – Manual | Manual + DRO | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.2 mm | Manual |

| PEHU LMS15-04 + 112S (3.3) | 112S 3.3Nm Servo Control | Semi-Automatic (Stroke Control) | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.2 mm | Manual |

| PEHU LMS30-04 + 112S (3.3) | 112S 3.3Nm Servo Control | Semi-Automatic (Stroke Control) | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS30-04 + 112 (3.3) | 112 3.3Nm Servo Control | Fully Automatic | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS45-04 + 112S (3.3) | 112S 3.3Nm Servo Control | Semi-Automatic (Stroke Control) | Manual | Attaches to existing roller track system | 630 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS45-04 + 112 (3.3) | 112 3.3Nm Servo Control | Fully Automatic | Manual | Attaches to existing roller track system | 630 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS45-04 + 112 (5.0) | 112 5.0Nm Servo Control | Fully Automatic | Manual | Attaches to existing roller track system | 630 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS60-06 | 112 5.0Nm Servo Control | Fully Automatic | Hydraulic / Electric | Integrated into a seperate dedicated frame | 830 | 6,000 (4.5m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS80-06 | 112 5.0Nm Servo Control | Fully Automatic | Hydraulic / Electric | Integrated into a seperate dedicated frame | 1,100 | 6,000 (4.5m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

Features

- PEHU LMS30/45/60/80 – Powered programmable positioning of stop unit

- PEHU LMS30/45/60/80 – Servo motor with rotary encoder to ensure positioning accuracy

- Precision linear rail guidance system

- Digital read out of stop position

- Increased cutting accuracy by eliminating measuring errors

- Increased productivity – one set up for multiple cuts at same length

- Stop runs on precision linear guidance rail

- Rotary encoder ensures positioning accuracy

- +/- 0.1mm Repeatability

- Ideal for use with saws, drills and steelworkers

- Roller track available separately

Options

- Manual or powered flip up stop to allow cutting of longer material

- Pneumatic or hydraulic gripper or material clamp on the feeder unit

- Material Stop Warning Lamp

- Control Display in Arm

- Interconnection Kit (Used for linking the PEHU system with the machine it is paired with for further automation)

- Extension Kits for PEHU Rail

- Gravity or powered roller track to suit

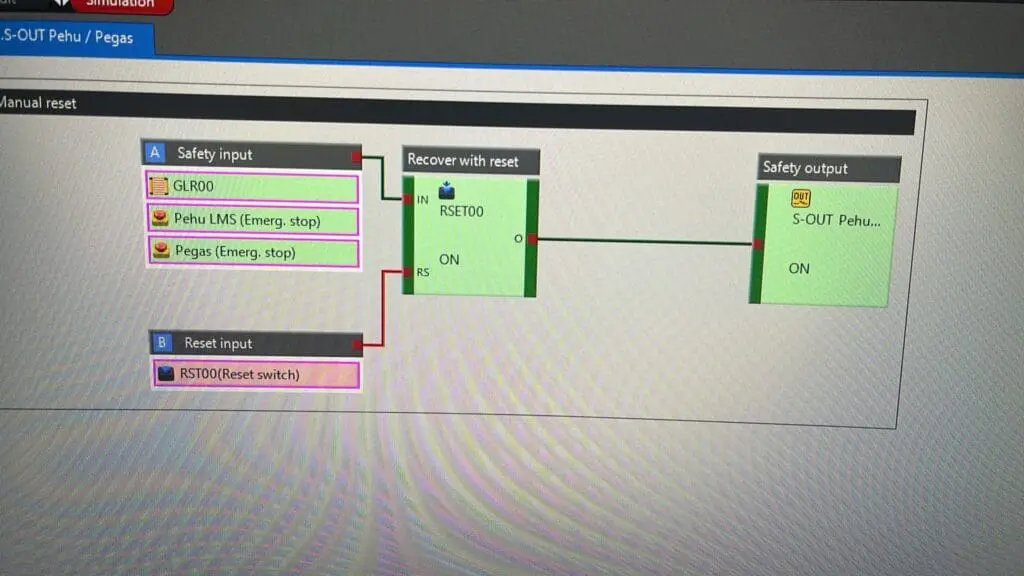

- Light Guard Safety System

The PEHU LMS30 to PEHU LMS80 are powered measuring system models which can be configured as either auto-measuring or auto-feeding systems. The operator enters the required stop positions into the NC control and the system automatically runs through the program until it is completed. Specific systems can be configured to work with saws, drills and steelworkers or punching machines.

The different models are configurable for varied capacities, and levels of automation.

PEHU LMS 30

The PEHU LMS 30 is the ideal length measuring system for positioning lighter to medium-heavy materials and can be used both as a stop system and as a push-on system.

The PEHU LMS 30 length measuring system can be used on your sawing machine, drilling machine, punching machine and shearing machine and can be placed on the left or right side of the machine tool.0

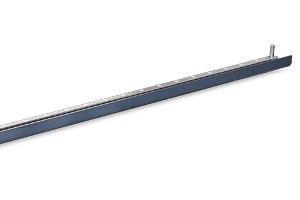

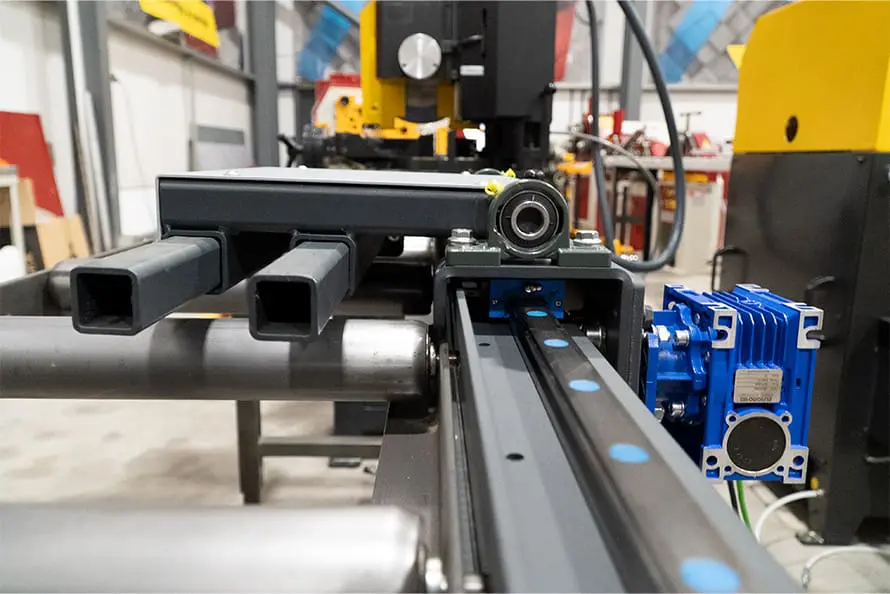

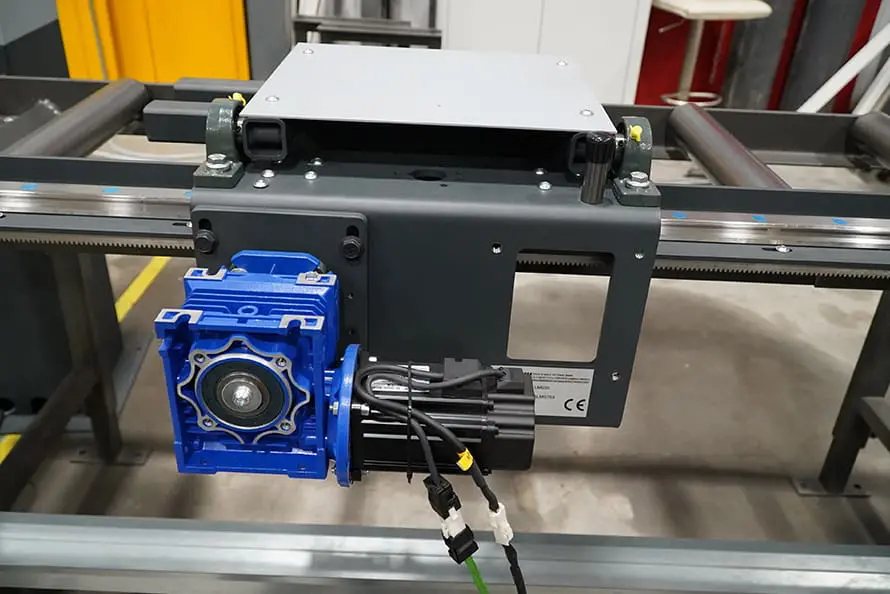

The mechanical part of the PEHU LMS 30 length measuring system consists as standard of a four meter long angle line with a servo-controlled stop carriage.

Angle line The PEHU

LMS 30 length measuring system is supplied as standard on a uniquely developed angle line with a linear guide of 30 mm. Due to the sophisticated design, it can be extended to any desired processing length.

Stop carriage

The servo-controlled stop carriage of the PEHU LMS 30 is equipped with two backlash-free linear carriages and is supplied as standard with a manually folding stop.

The PEHU LMS 30 is easy to install on any new or existing roller conveyor.

Depending on the use of the length measuring system, there is a choice between the semi-automatic PEHU 112S control (standard) and the fully automatic PEHU 112 control.

PEHU 112S servo control

The PEHU LMS 30 length measuring system is supplied as standard with the PEHU 112S – 3.3 Nm servo control . This control consists of a control box, cabling, angle transmission and 3.3 Nm servo motor. With the PEHU 112S you can turn the PEHU LMS 30 into an easy-to-operate and efficient semi-automatic stop system.

PEHU 112 servo control

Do you want to use your length measuring system not only as a semi-automatic stop system, but also as a fully automatic push-up system? Then the PEHU 112 – 3.3 Nm control is the right choice.

PEHU LMS 45

The PEHU LMS 45 is the ideal length measuring system for positioning medium to heavy materials and can be used both as a stop system and as a push system.

The PEHU LMS 45 length measuring system can be used on your sawing machine, drilling machine, punching machine and shearing machine and can be placed on the left or right side of the machine tool.

The mechanical part of the PEHU LMS 45 length measuring system consists of a four meter long angle line with a servo-controlled stop carriage.

Angle line The PEHU

LMS 45 length measuring system is supplied as standard on a uniquely developed angle line with a linear guide of 45 mm. Due to the sophisticated design, it can be extended to any desired processing length.

Stop carriage

The stop carriage of the PEHU LMS 45 is equipped with two backlash-free linear carriages and is supplied as standard with a manually folding stop.

The PEHU LMS 45 is easy to mount on any new or existing roller conveyor.

Depending on the use of the length measuring system, there is a choice between the semi-automatic PEHU 112S control (standard) and the fully automatic PEHU 112 control.

PEHU 112S servo control

The PEHU LMS 45 length measuring system is supplied as standard with the PEHU 112S – 3.3 Nm servo control . This control consists of a control box, cabling, angle transmission and 3.3 Nm servo motor. With the PEHU 112S you turn the PEHU LMS 45 into an easy-to-operate and efficient semi-automatic stop system.

PEHU 112 servo control

Do you want to use your length measuring system not only as a semi-automatic stop system, but also as a fully automatic push-up system? Then the PEHU 112 control is the right choice. Depending on the load, there is a choice between the 3.3 Nm and 5.0 Nm version.

PEHU LMS 60

The ideal length measuring system for positioning heavy to very heavy materials on a sawing machine. The material is positioned with a high degree of accuracy. The PEHU LMS 60 can be placed either to the left or to the right of the machine tool.

The PEHU LMS 60 length measuring system is extremely suitable for use in very heavy industry.

PEHU LMS 60 is an NC controlled system with a PEHU 112 – 5.0 Nm servo control. The PEHU LMS 60 is supplied as standard on a heavy UNP Frame, a hydraulic or electric folding stop and a user-friendly servo control. The stop is fitted with a sensor to switch the driven roller conveyor to a crawl speed, after which the material comes into contact with the stop in a controlled manner and stops the roller conveyor. A contact sensor has also been placed here that switches on a lamp on the stop carriage, so that you can see that it is lying against the stop. The PEHU LMS 60 length measuring system is easy to assemble and is separate from the roller conveyor (and can therefore be used anywhere!).

PEHU 112 – 5.0 Nm

The measuring system is equipped with the PEHU 112-5.0 Nm servo control . This is a very accurate 1-axis point-to-point control. The control is used as a stop.

PEHU LMS 80

The ideal length measuring system for positioning heavy to very heavy materials on a sawing machine. The material is positioned with a high degree of accuracy. The PEHU LMS 80 can be placed either to the left or to the right of the machine tool.

The PEHU LMS 80 length measuring system is extremely suitable for use in very heavy industry.

PEHU LMS 80 is an NC controlled system with a PEHU 112 – 5.0 Nm servo control. The PEHU LMS 80 is supplied as standard on a heavy UNP Frame, a hydraulic or electric folding stop and a user-friendly servo control. The stop is fitted with a sensor to switch the driven roller conveyor to a crawl speed, after which the material comes into contact with the stop in a controlled manner and stops the roller conveyor. A contact sensor has also been placed here that switches on a lamp on the stop carriage, so that you can see that it is lying against the stop. The PEHU LMS 80 length measuring system is easy to assemble and is separate from the roller conveyor (and can therefore be used anywhere!).

PEHU 112 – 5.0 Nm

The measuring system is equipped with the PEHU 112-5.0 Nm servo control . This is a very accurate 1-axis point-to-point control. The control is used as a stop.

PEHU Optional Extras

You can expand the PEHU Measuring Systems with additional options, as detailed below;

PEHU Extension

PEHU length measuring systems are extendable per meter. Extension consists of:

– Special angle line (powder coated Ral 7016)

– Linear rail

– Rack

– Cable duct + support + cover

– Cable carrier

PEHU Automatic Folding Stop

PEHU length measuring systems LMS15/30/45 are supplied as standard with a manually foldable stop. With the LMS15/30/45 you can opt for an extra support that lowers the stop in a controlled manner by means of a gas spring.

With the LMS 45 you can also opt for an electrically foldable stop. The stop is provided with a drive that you can operate from the control unit (pehu 112 cabinet). In some situations it is also possible to automatically fold up the stop during the retrack movement. The PEHU LMS 60/80 are equipped with a foldable stop as standard.

PEHU Material Stop Light

The PEHU stops can be equipped with a stop lamp, which lights up when material is against the stop. This is a handy aid for longer lengths.

PEHU Material Clamp

In order to prevent the material from rolling during pushing, PEHU has developed its own material clamp, which can clamp to any desired width by means of a fast sliding system. The pusher runs over a linear guide and is secured by means of a pin, after which it is tightened by hand. As an option, one can choose a pneumatic or hydraulic clamping.

PEHU Control Display in Arm

Control display is hung on the machine. Control cabinet with driver(s) is placed elsewhere. Maximum cable length between display and control cabinet is 8 meters. Control display hangs on a hinged part so that the reading angle is adjustable and will be easy to read for everyone.

PEHU Interconnection Kit

The kit is necessary if you are going to use a coupling between the push system and the processing machine. This ensures the communication between both systems. With this kit you can make a semi-automatic machine into a fully automatic machine. Or you can still feed a manually operated machine automatically without operating the control.