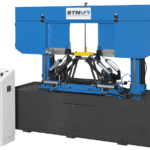

BTM TT 350 Rebar Bundle Cutting Semi-Automatic Bandsaw

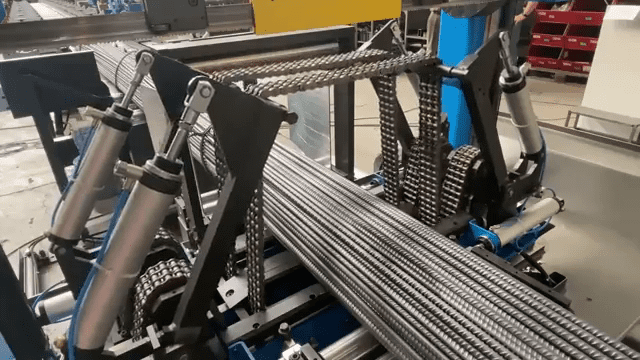

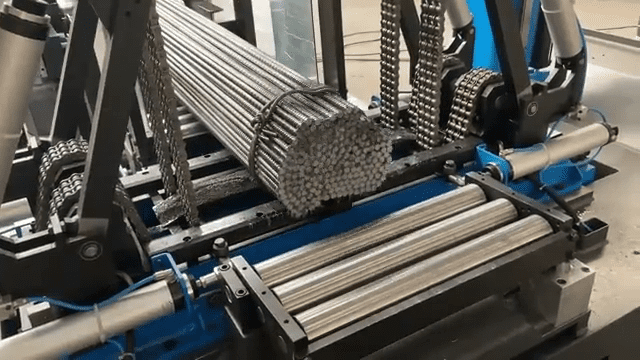

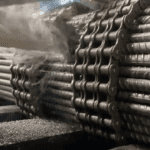

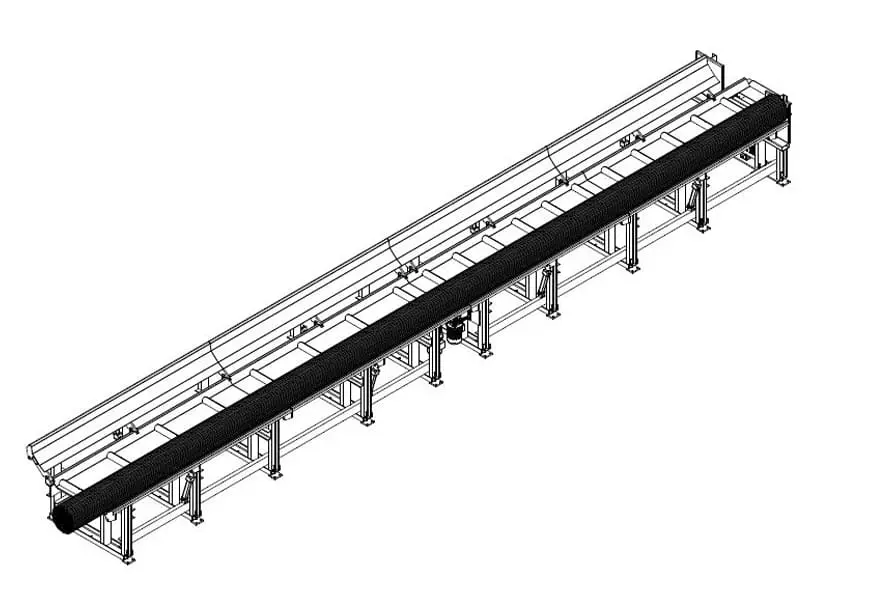

This heavy-duty, semi-automatic twin column bandsaw from BTM features automatic bow rise and fall, and is purpose built for cutting bundles of re-bar. With a double chain clamping vice, it securely grips bundles of rebar for optimal and precise cutting.

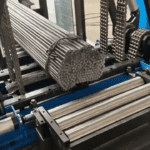

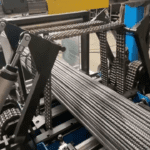

Paired with optional automatic loading and unloading systems, this system can cut through up to 350mm bundles of rebar with relative ease for a fast and efficient production line.

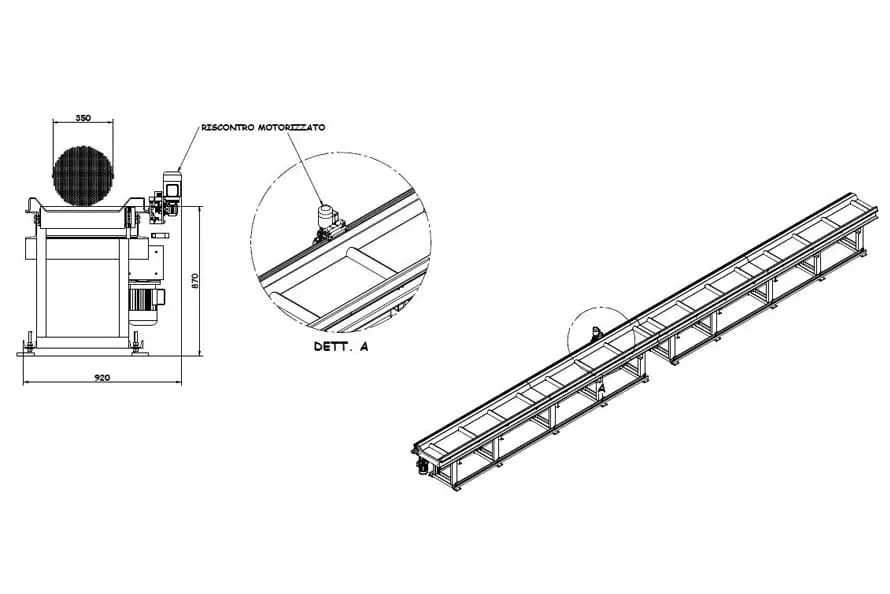

| MODEL | TT 350 | |

| Capacity | 90° | |

| ◯ Round | mm | 350 |

| Bed Height | mm | 870 |

| Blade Size | mm | 5,800 x 41 x 1.3 |

| Blade Speed | m/min | 20 – 100 |

| Cutting Speed | mm/min | 0 – 200 |

| Fast Downfeed | mm/min | 3,500 |

| Blade Motor | Kw | 3 |

| Cooling Pump Motor | Kw | 0.37 |

| Hydraulic Pump Motor | Kw | 4 |

| Chip Conveyor Motor | Kw | 0.09 |

| Length | mm | 1,150 |

| Width | mm | 3,200 |

| Height | mm | 2,400 |

| Weight | kg | 2,200 |

Features

- Bow and Base in heavy-duty steel construction

- Hydraulic Blade Tensioning

- Vertical bow descent on ball bearing guides

- Chip Conveyor

- Dual Chain vice for securing bundles of re-bar

- End stop for aligning re-bar

- Hydraulic top clamping

- PLC Controller

Options

- 7” or 10” Touch Screen Control

- Unit (required for powered infeed / outfeed roller tracks)

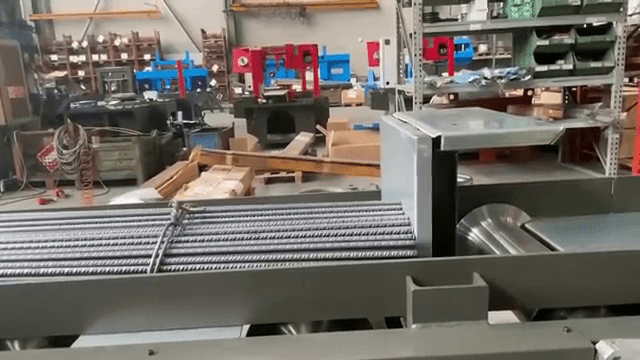

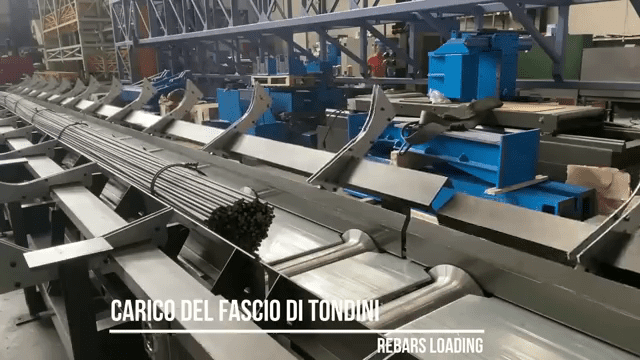

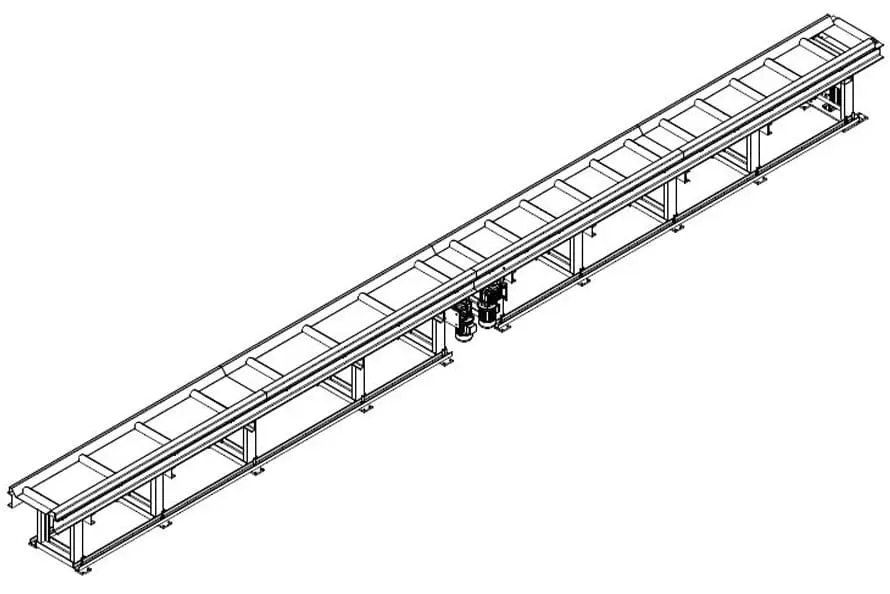

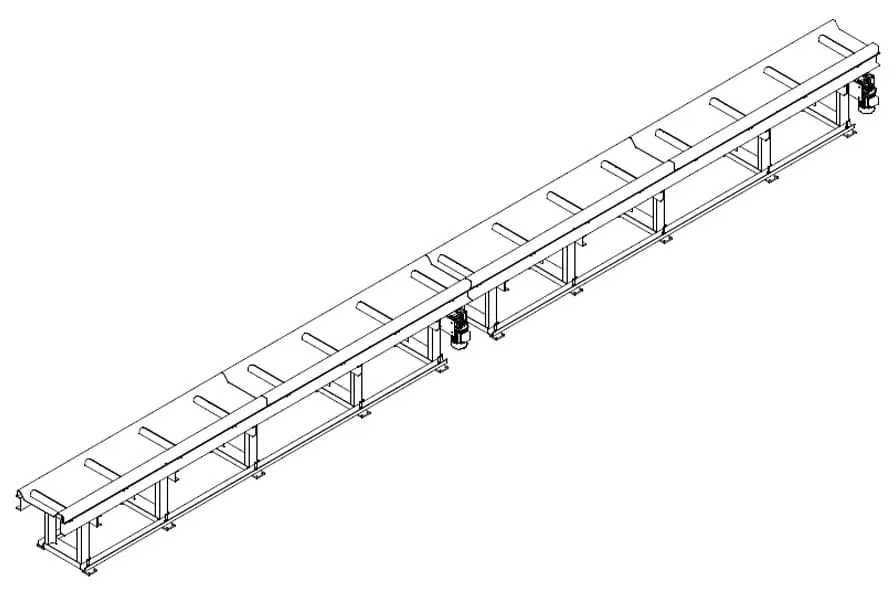

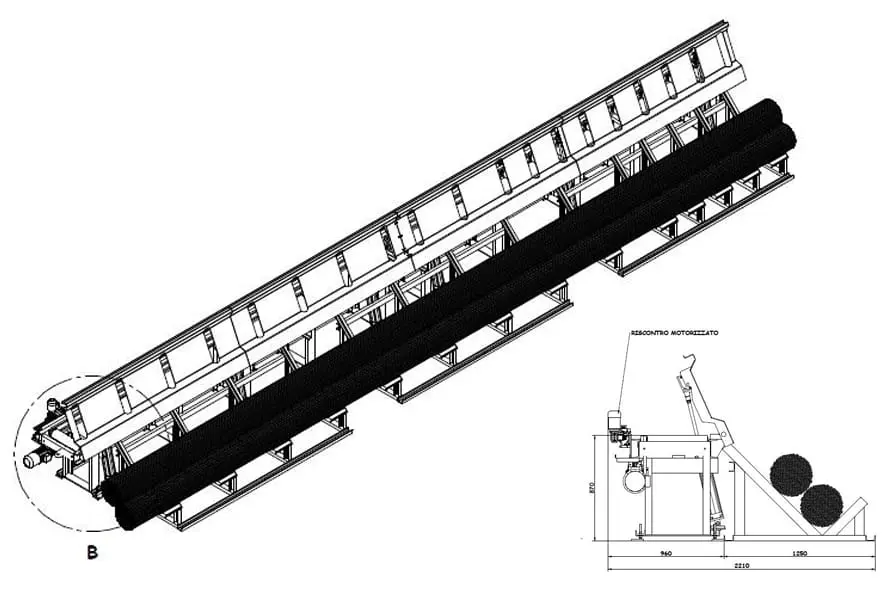

- (A) Powered infeed roller track with pneumatic stop for bundle alignment – 6m lengths

- (B) Powered infeed roller track with mechanical stop for bundle alignment (Three-station loading storage) – 6m lengths

- (C) Powered outfeed roller track – 6m lengths

- (D) Powered outfeed roller track equipped with powered length stop with hydraulic lift – 6m lengths

- (E) Powered outfeed roller track equipped with powered length stop with hydraulic lift and material storage – 6m lengths

- BTM Teleservice Support

- Laser Line (for Semi-Auto mode)

- Spray mist cooling system

- Roller track and measuring systems

BTM TT-350 Semi-Automatic Twin Column Bandsaw

Precision Cutting for Rebar Bundles

The BTM TT-350 is a heavy-duty, semi-automatic twin-column bandsaw designed for high-efficiency cutting of rebar bundles. Engineered for durability and precision, this robust saw is ideal for fabricators, construction suppliers, and metalworking businesses requiring a reliable and high-performance rebar cutting solution.

Key Features

Automatic Bow Rise and Fall

The TT-350 features an automatic bow rise and fall system, ensuring smooth and controlled cutting cycles. This automation reduces operator involvement, enhances productivity, and optimises cutting accuracy.

Double Chain Clamping Vice for Secure Holding

To achieve precise, repeatable cuts, the machine is equipped with a double chain clamping vice, ensuring a firm and stable grip on rebar bundles throughout the cutting process. This feature minimises material movement, delivering clean and consistent cuts every time.

Efficient Bundle Cutting – Up to 350mm Capacity

Designed to handle large workloads, the TT-350 efficiently cuts through rebar bundles up to 350mm in diameter. Its powerful cutting capability makes it an excellent choice for high-volume metal processing.

Enhance Productivity with Optional Automation

For maximum efficiency, the TT-350 can be paired with automatic loading and unloading systems. This integration allows for a seamless production line, reducing manual handling and increasing throughput in demanding industrial environments.

Why Choose the BTM TT-350?

- Specifically designed for rebar cutting, ensuring industry-specific performance

- Automatic operation improves speed and consistency

- Heavy-duty twin-column construction for long-lasting durability

- Secure clamping system for enhanced precision

- Expandable with automation options for improved workflow efficiency

Ideal for:

- Rebar processing facilities

- Construction material suppliers

- Fabrication workshops

- High-volume metal cutting applications

Invest in the BTM TT-350 Semi-Automatic Twin Column Bandsaw to streamline your rebar cutting operations and boost your production efficiency.