Baykal BPM 1225/30 CNC Punch Press

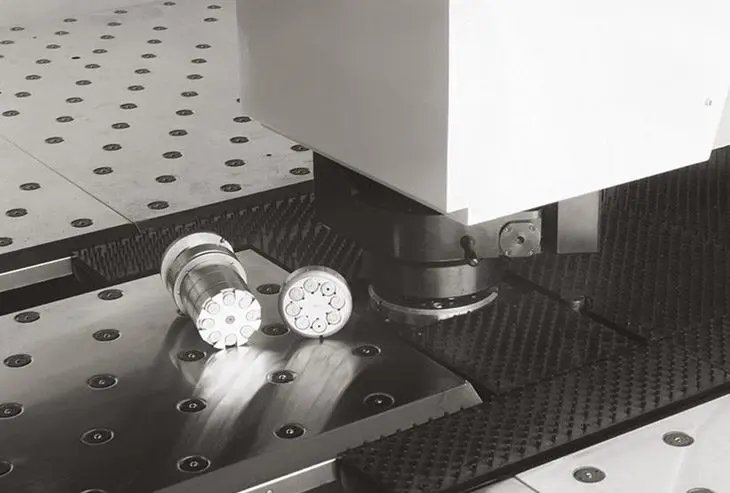

The Baykal BPM 1225-30 CNC Punch Press features CNC Auto Indexing of the punching head with a multi tool fitted as standard. The machine is manufactured to a very high standard using Finite Element Analysis software to ensure that there is minimum deflection in the machine body even under maximum load. All components used are manufactured to a very strict tolerance utilising hardened component where applicable. A centralised lubrication system ensures that any moving parts receive a consistent amount of lubricant. The machine is designed for high production with a maximum speed of 600 strokes per minute when nibbling in 1mm pitch. The BPM machine uses Lantek CAM software which includes automatic nesting of components onto the sheet.

This product is now discontinued however we'd be happy to discuss alternative options with you. If you're looking for consumables, servicing or spare parts for this product, please contact our sales team.

VIEW AlTERNATIVES| MODEL | BPM 1225/30 | |

| Punching Force | Tonne | 30 |

| Tool Rotation Method | Indexable Multi Tool | |

| No of Tools in Multi Tool | 3 or 8 | |

| Tool Station Size | D | |

| Tool Station Rotation | Deg | 360 |

| CNC Controlled Axes | X, Y, Z, C1 & C2 | |

| X Axis Stroke (without repositioning) | mm | 2540 |

| X Axis Repositioning | Yes | |

| Y Axis Stroke | mm | 1270 |

| X Axis Speed | m/min | 90 |

| Y Axis Speed | m/min | 60 |

| X & Y Axis Combined Speed | m/min | 108 |

| C1 & C2 Rotational Speed | RPM | 40 |

| Z Axis Stroke | mm | 30 |

| Nibbling Rate – 1mm Pitch | hits/min | 600 |

| Maximum Sheet Weight at Maximum Speed | kg | 170 |

| Maximum Sheet Thickness | mm | 6.4 |

| Punching Accuracy | mm | 0.1 |

| Repeatability | mm | 0.04 |

| Maximum Punching Diameter | mm | 88.9 |

| Number of Material Clamps | 2 | |

| Clamping Force Adjustment Method | CNC | |

| Working Height of Table | mm | 880 |

| Oil Tank Capacity | litre | 350 |

| Motor Power | kW | 11 |

| Length | mm | 1980 |

| Width | mm | 4220 |

| Height | mm | 4940 |

| Weight | kg | 12700 |

Features

- ‘C’ Frame design tested by Finite Element Analysis software, precisely machined and stress relieved to ensure high precision performance

- Hydraulic punching with indexable tool station through 360° in increments of 0.001°

- Fitted with one indexable D station size multi tool (3 or 8 station)

- Punching, cutting and forming processes – subject to optional tooling fitted – controlled by the CNC according to material type and thickness

- Capable of producing not only 2D components but when fitted with special tools can create 3D forms which wouldn’t be possible when using a profiling process

- High nibbling rate of 600 hits per minute in 1mm pitch

- High capacity motors and precision guides on all axes able to reach high operational speeds

- Rigid beam with fitted with two sheet clamps capable of positioning sheets of up to 6.4mm thickness and up to 170kg in weight

- Very accurate repeatability of 0.04mm

- Clamping force adjusted by CNC from 100 to 1000kgf

- Repositioning feature

- 2500 x 1250mm Ball transfer and brush table combination

- Ergonomic free standing CNC control console with 12” TFT colour monitor

- Bosch Rexroth Control System installed on industrial PC running Windows XP with 256MB RAM and 40GB Hard Disc

- High processing speeds and data transfer rates

- Lantek Nesting Software with the ability to import a variety of file formats including DXF with additional design model allowing parts to drawn from within the software. The Lantek software incudes includes a powerful nesting module

- CE compliant light barrier system preventing entry to the working area

Options

- Additional indexable D Station size multi tool

- Reductions to C, B and A station sizes

- Additional beam clamp

- Additional license for Lantek CAM Software

- Single punching tools and special forming tools

- Special coated tools for stainless steel