Our Bema MG32C Pillar Drill was introduced ten years ago now and remains incredibly popular today, both in its 240V and 415V variants. Both incorporate larger columns, larger working tables and a larger base plate and both are heavy duty, robust and made to exacting standards, filling the gap perfectly between lighter weight, lower quality machines and much more costly geared head machines.

Changing the speeds on the Bema MG32C is a relatively straightforward process but as with so many things, it’s a process that needs to be followed systematically and in the right order to do it well and safely. With that in mind here is our step by step guide to changing the gears on your Bema Pillar Drill.

First and foremost, isolating the machine is really important, only when that is done can we make a start by safely releasing the machine’s tension bolt. With the tension bolt released we then swing the motor towards the column of the machine, this has the effect of slackening the tension on the belts.

When that is done and with the machine still isolated, we then access the belts at the top of the column by unhinging the clips and sliding back the black cover as you can see in the video. Lowering the right hand belt releases even more slack, allowing more adjustment on the left hand belt.

At this point the speed chart on your pillar drill becomes very important; it tells you whereabouts on the spindles to place your belts to achieve the speed you need, that can be anything from 100 to 2150 rpm on the Bema MG32C, there are also very useful images of each spindle above the chart, so select the belt positions that you need.

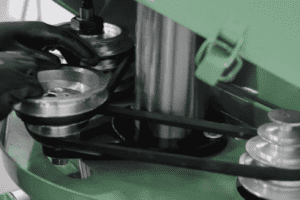

Positioning your belts on to the correct spindle positions doesn’t need to be a painstaking process, just gently persuade the belt in the correct direction whilst manually turning the gear wheels at the same time as demonstrated in our video. Wearing the correct PPE and being mindful of where exactly your fingers are whilst performing this stage is a very good idea…

With that done, simply replace your cover and secure it safely, replace the black cover, then you are ready to ensure your motor is correctly positioned before reapplying your machine’s tension bolt and turning it back on, to use safely and accurately at just the speed you need.

To learn more about our Bema MG32C Pillar Drills, get in touch today, or give us a call on 01432 346 580

Published 21st February 2018