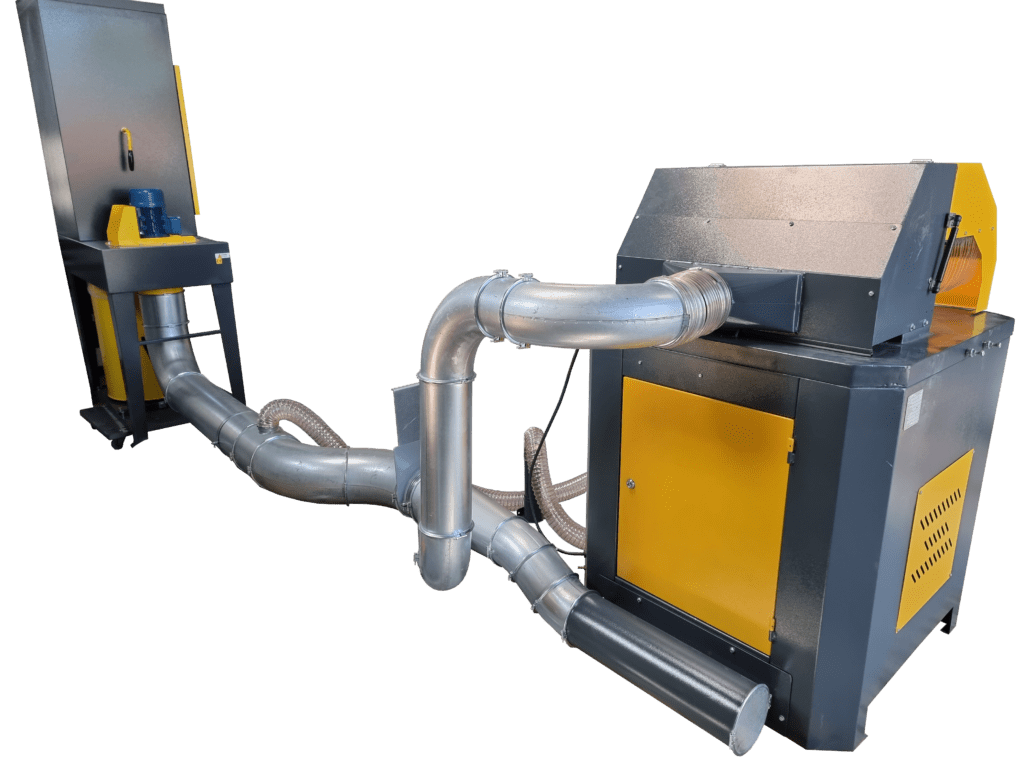

Sterling SAR 420 SA Semi-Automatic Aluminium Circular Saw

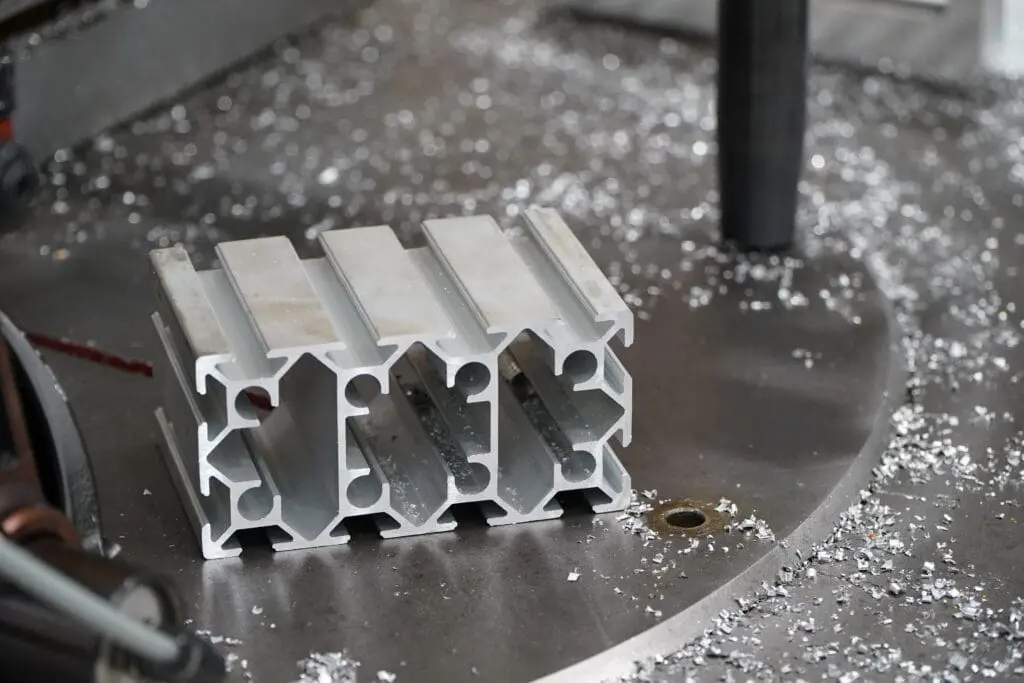

The Sterling SAR420 semi-automatic aluminium circular saws are designed for working with aluminium sections and extrusions. Featuring high blade speeds and semi-automatic operation, with a full enclosures for ultimate safety. These machines use TCT toothed cutting blades which are available in a range of tooth pitches depending on the material section and required finish.

We can also supply circular saw blades and coolant too, these can be purchased directly off our tooling website.

| MODEL | SAR 420SA | ||

| Capacity | 90° | 45° L + R | |

| ◯ Tube | mm | 160 | – |

| □ Box Section | mm | 140 x 140 | 120 x 120 |

| ▭ Widest Cut | mm | – | – |

| Bed Height | mm | 960 | |

| Blade Size | mm | 420ø x 32 bore | |

| Blade Speed | rpm | 3000 | |

| Motor | Kw | 3.0 | |

| Length | mm | 800 | |

| Width | mm | 850 | |

| Height | mm | 1400 | |

| Weight | Kg | 210 | |

| Operation | Semi Automatic | ||

| Vice | Pneumatic | ||

Features

- Fast aluminium cutting

- Adjustable blade feed rate

- Twin pairs of vertical and horizontal pneumatic clamps

- Mitring head to 180° left and right

- Mitre clamp for locking off at Intermediate angles

- Flat solid bed

- Full enclosure with interlock safety switch

- Air gun for swarf removal

- 2x 3m roller tables, including length stopper on the exit

Options

- Measuring conveyor right side 4, 5 or 6m

- Roller conveyor left side 4, 5 or 6m

- Cooling system for cutting aluminium

- Hydro-check for cutting aluminium profiles (hydraulic speed setting)

- Automatic measurement conveyor

- Extraction System (Highly recommended)

The Sterling SAR semi-automatic range of circular saws are designed for working with aluminium sections and extrusions. All models feature high blade speeds and are semi-automatic operated with a full enclosures for ultimate safety. These machines use TCT toothed cutting blades which are available in a range of tooth pitches depending on the material section and required finish. The up-stroking 420 blade has a speed of 3000RPM and comes complete with pneumatic clamps and 2x3m of roller track as standard.

Increased Efficiency

Looking to further increase the efficiency in your workshop? Additional roller track for the entry and exit of your saw can help improve efficiency further still. With the roller track in place, workers can quickly and effectively load and unload material. Coupled with measuring systems workers can work faster and more accurately.

Why does Aluminium cutting require Extraction?

The dust from cutting Aluminium is highly flammable. It can ignite spontaneously in air. It will also react with water to generate flammable gaseous hydrogen and heat.

How Dust Explosions Occur

In addition to the familiar fire triangle of oxygen, heat, and fuel (the dust), dispersion of dust particles in sufficient quantity and concentration can cause rapid combustion known as a deflagration. If the event is confined by an enclosure such as a building, room, vessel, or process equipment, the resulting pressure rise may cause an explosion. These five factors (oxygen, heat, fuel, dispersion, and confinement) are known as the “Dust Explosion Pentagon”. If one element of the pentagon is missing, an explosion cannot occur.

Catastrophic Secondary Explosions

An initial (primary) explosion in processing equipment or in an area where fugitive dust has accumulated may dislodge more accumulated dust into the air or damage a containment system (such as a duct, vessel, or collector). As a result, if ignited, the additional dust dispersed into the air may cause one or more secondary explosions. These can be far more destructive than a primary explosion due to the increased quantity and concentration of dispersed combustible dust. Many deaths in past accidents, as well as other damage, have been caused by secondary explosions.

The solution

We therefore strongly recommend that any and all Aluminium cutting equipment is supplied with an extraction system of some kind. We have a system set-up for the SRA Upcutting Saw range, speak to a member of the sales team for more information.

Bandsaw & Circular Saw Technology Fully Explained

10th April 2025 by Mark Bradley

Maximise the life of your Circular Saw Blades with these top tips!

12th November 2024 by Dave Hargest

GoldCut Circular Saw Blade Selection Guide

12th November 2024 by Dave Hargest

The Hidden Dangers of Aluminium Dust from High-Speed Cutting

27th August 2024 by Dave Hargest