Promotech BM-25 Plate Bevelling Machine

The Promotech BM-25 Plate Bevelling Machine is a robust, portable tool for creating bevels up to 25 mm wide. Featuring a powerful motor and face milling head, it ensures smooth and precise performance in workshops or on-site.

With variable spindle speed, it optimises cutting conditions for different materials. The milling depth and bevel angle, adjustable between 0 and 90 degrees, can be changed easily without tools, boosting productivity and versatility. The BM-25 combines efficiency with user-friendly operation.

| MODEL | BM-25 | |

| voltage | v | 220 – 240 |

| Power | kw | 2.2 |

| Spindle speed | rpm | 1800-5850 |

| Bevel angle | ° | 0 – 90 |

| Max bevel width | mm | 25 |

| Weight | kg | 12.5 |

Features

- maximum 25 mm bevel width (more than one pass could be required)

- continuously adjustable bevel angle between 0 and 90 degrees – one milling head in use only

- powerful motor with electronic speed control between 1800 –5850 rpm to work with various materials

- a single head works with the face milling method, allowing less milling resistance and effort for the operator

- overload protection to prevent motor damage

- continuous milling depth adjustment to fully control the bevelling process

- adjustable handle and grip for comfort and ergonomics

Options

Introduction to the Promotech BM-25

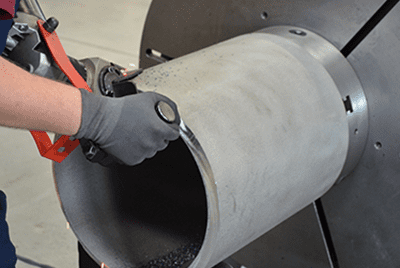

The Promotech BM-25 Plate Bevelling Machine is a heavy-duty, portable tool designed for professional applications that require precision and efficiency. Capable of creating bevels up to 25 mm wide, the BM-25 combines power and versatility, making it a reliable choice for workshops and on-site projects. With its user-friendly design, robust construction, and innovative features, this machine is ideal for industries such as metal fabrication, welding preparation, and construction.

Key Features

High Bevelling Capacity

The BM-25 stands out for its ability to bevel straight edges up to 25 mm in width. Its powerful motor and face milling bevelling head work together to ensure smooth, precise operation. Whether you need to prepare edges for welding or create custom bevel angles, the BM-25 delivers consistent results.

Variable Spindle Speed

One of the most notable features of the BM-25 is its variable spindle speed, allowing operators to optimise cutting conditions based on the material being processed. This flexibility ensures high-quality bevels on a range of materials, including steel, aluminium, and alloys. The adjustable speed also contributes to reduced wear on tooling, improving the machine’s efficiency and longevity.

Adjustable Milling Depth and Bevel Angle

The BM-25 offers a continuously adjustable milling depth and bevel angle between 0 and 90 degrees. What sets this feature apart is the convenience it provides—no additional tools are required to make adjustments. This allows operators to quickly adapt the machine to different tasks, reducing downtime and enhancing productivity.

Built for Durability and Portability

Heavy-Duty Construction

The BM-25 is built to withstand the rigours of demanding industrial environments. Its durable components and high-quality materials ensure long-term reliability, even under heavy use. The robust design minimises the risk of mechanical failure, making it a dependable investment for businesses that prioritise efficiency and performance.

Portable Design

Despite its heavy-duty capabilities, the BM-25 is designed with portability in mind. Its compact size and ergonomic design make it easy to transport and operate in various settings, from workshops to construction sites. The portability of the BM-25 enhances its versatility, enabling users to handle beveling tasks wherever they are needed.

User-Friendly Operation

Intuitive Controls

The BM-25 is equipped with intuitive controls that simplify its operation, even for less experienced users. The clear layout of the controls ensures that adjustments to spindle speed, milling depth, and bevel angle can be made quickly and accurately. This user-friendly design reduces the learning curve and allows operators to focus on achieving high-quality results.

Tool-Free Adjustments

Another feature that contributes to the machine’s ease of use is its tool-free adjustment system. Operators can modify the bevel angle and milling depth without the need for additional tools, saving time and effort. This feature is particularly beneficial for projects that require frequent changes to bevel specifications.

Versatility Across Applications

Welding Preparation

The BM-25 is an excellent choice for welding preparation, as it can create precise bevels that improve weld penetration and strength. Its ability to handle a wide range of bevel angles makes it suitable for various welding techniques, from butt joints to V-grooves.

Metal Fabrication

In metal fabrication, the BM-25 excels at preparing edges for painting, coating, or assembly. Its smooth and accurate milling capabilities ensure a clean finish, reducing the need for additional processing. The machine’s adjustable settings also make it suitable for custom fabrication projects.

Construction and Maintenance

For construction and maintenance tasks, the BM-25’s portability and durability are key advantages. It can be used on-site to bevel plates and edges for structural components, ensuring that materials are properly prepared for installation or repair.

Efficiency and Cost-Effectiveness

Minimal Downtime

The BM-25 is designed to minimise downtime, thanks to its reliable construction and quick adjustment features. Operators can quickly switch between tasks without the need for extensive setup, keeping projects on schedule.

Long Tool Life

The variable spindle speed not only improves cutting performance but also extends the life of the milling head and other components. By reducing wear and tear, the BM-25 helps businesses save on maintenance and replacement costs over time.

Safety Features

Stable Operation

The BM-25 is engineered for stable and secure operation, even when working with heavy materials. Its solid base and ergonomic design ensure that the machine remains steady during use, reducing the risk of accidents.

Built-In Safety Mechanisms

The machine is equipped with built-in safety mechanisms that protect operators and ensure reliable performance. These features provide peace of mind for businesses that prioritise workplace safety.

Conclusion

The Promotech BM-25 Plate Bevelling Machine is a powerful, portable, and user-friendly tool that offers exceptional performance across a variety of applications. Its high bevelling capacity, adjustable settings, and robust construction make it a reliable choice for industries such as metal fabrication, welding preparation, and construction.

By investing in the BM-25, businesses can achieve precise, high-quality bevels while benefiting from increased efficiency, reduced downtime, and long-term cost savings. Whether in a workshop or on-site, the BM-25 delivers the performance and reliability needed to meet the demands of modern industry.