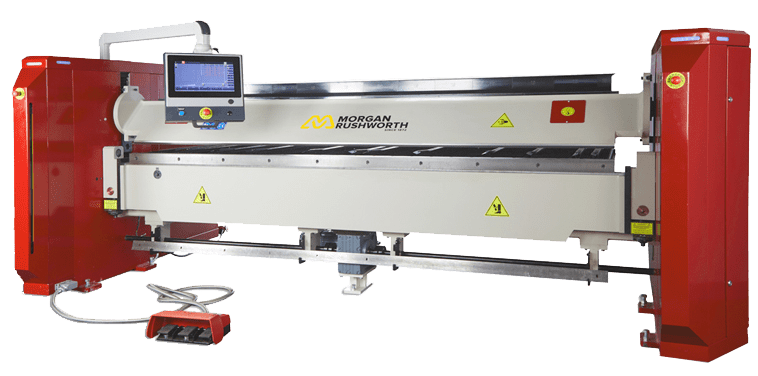

Morgan Rushworth EXL Folding Machine

The Morgan Rushworth EXL CNC folders feature a rotating upper beam with a straight rail and high divided tools, used in the same program without manual changes. This ensures high accuracy and productivity, ideal for rectangular panels with return edges. Powered by servo motors, the machine offers precision and durability with a single tool setup.

The integrated back gauge and support table enable single-operator handling of large sheets. The 2D touch screen CNC controls all movements, with an optional 3D touch screen for enhanced visualisation, feasibility checks, and optimised bending sequences.

| Model | EXL 2050.40 | EXL 2550.35 | EXL 3200.30 | EXL 4200.25 | |

| SKU | M2087 | M2088 | M2089 | M2090 | |

| Bending Width | mm | 2050 | 2550 | 3200 | 4200 |

| Bending Thickness – Mild Steel | mm | 4 | 3.5 | 3 | 2.5 |

| Bending Thickness – Stainless Stainless | mm | 3 | 2.5 | 2 | 1.5 |

| Bending Thickness – Aluminium | mm | 6 | 5 | 4 | 3.5 |

| Stroke Depth | mm | 250 on 180° | 250 on 180° | 250 on 180° | 250 on 180° |

| Back Gauge | mm | 1500 | 1500 | 1500 | 1500 |

| Clamping Beam Axis Speed | mm/sec | 60 | 60 | 60 | 60 |

| Folding Beam Axis Speed | mm/sec | 85 | 85 | 85 | 85 |

| Back Gauge Axis Speed | mm/sec | 200 | 200 | 200 | 200 |

| Clamping Beam Motor | kW | 2 x 5.5 | 2 x 5.5 | 2 x 5.5 | 2 x 5.5 |

| Folding Beam Motor | kW | 2 x 3 | 2 x 3 | 2 x 3 | 2 x 3 |

| Back Gauge Motor | kW | 0.75 | 0.75 | 0.75 | 0.75 |

| Length | mm | 2300 | 2300 | 2300 | 2300 |

| Width | mm | 3750 | 4250 | 4950 | 5950 |

| Height | mm | 2100 | 2100 | 2100 | 2100 |

| Weight | kg | 5700 | 6300 | 7100 | 8050 |

Features

- Bending angle from 0 – 150 degrees

- 20 degree 1mm sharp nose clamping beam rail with 25mm clearance on one side of rotating beam

- 90mm high divided box tools on other side of rotating beam

- 10mm and 25mm wide folding beam rails

- Fast 1 metre powered backgauge integral to rear table with roller balls

- Flat lower beam with feather style backgauge fingers

- 15.6” 2D touch screen control on swinging arm for front and rear operation

- High speed and high pressure clamping

- Virtually no marking on material

- Safe edge can be achieved without tool change

- Very quiet with low energy consumption as motors only run when machine is working

- Manual folding beam adjustment

- Manual crowning system

- Front light guards barriers.

Options

- 3D CNC touch screen controller

- 2D and 3D offline software for PC

- Longer length back gauges with U and L shape configurations

- Squaring arm for rear backgauge table

- Stainless steel backgauge table

- Brush table to protect material

- Motorised folding beam adjustment

Morgan Rushworth EXL CNC Folders: Precision, Productivity, and Innovation

The Morgan Rushworth EXL range of CNC folders sets a new standard in sheet metal folding with advanced features designed to optimise precision, consistency, and productivity. A key innovation of the EXL range is its rotating upper beam, equipped with both a straight rail and a set of high divided tools. This unique design allows seamless integration of both tool types within the same program, eliminating the need for manual tool changes. With just a single initial setup, the system ensures efficiency and accuracy, making it ideal for a range of operations.

This versatility is particularly beneficial for rectangular panel work with return edges on all four sides. The machine folds the two long edges using the straight rail, then the upper beam automatically rotates to deploy the high divided tools for the shorter edges. The result is a fully completed panel with minimal operator intervention. Powered by durable servo motors, each axis delivers precise and consistent performance, ensuring long-term reliability.

Streamlined Material Handling for Large Sheets

The integrated back gauge and rear support table simplify the handling of large sheets by supporting the material’s weight during folding. This feature reduces the need for a second operator, allowing a single person to manage tasks traditionally requiring two. For high-production workshops, this capability boosts efficiency and lowers labour costs, making the EXL range an excellent investment.

The back gauge ensures precise positioning of the material, critical for achieving consistent results across a range of applications. From large panels to intricate parts, the combination of the back gauge and support table enhances accuracy and reduces errors, contributing to a smoother workflow.

Advanced CNC Control for Maximum Efficiency

The EXL CNC folders come equipped with an advanced 2D touch screen CNC control, offering an intuitive interface to manage clamping, beam rotation, folding, and back gauge movements. Programming can be performed directly on the machine or remotely via an office PC, providing flexibility and improving workflow efficiency.

An optional 3D touch screen CNC control is available, enabling enhanced visualisation of the folding process. Both controllers assist the operator by calculating job feasibility, developed length, and optimal bending sequences, including whether the material needs flipping or turning. This automation minimises errors, reduces setup times, and ensures consistent, high-quality output.

Five Key Benefits of the Morgan Rushworth EXL CNC Folders

- High Accuracy and Consistency

The rotating upper beam integrates two tool types, enabling precise and consistent results without manual tool changes. - Increased Productivity

Single tool setup and automated processes minimise downtime, allowing faster completion of tasks. - Single-Operator Handling

The integrated back gauge and support table allow large sheets to be folded by one operator, reducing labour costs. - Flexible Programming

The advanced CNC controls provide intuitive programming options, supporting both on-machine and remote setup, improving workflow efficiency. - Durable and Reliable Design

Servo motor-driven axes ensure long-lasting performance with minimal maintenance requirements.

Versatility for Diverse Applications

The Morgan Rushworth EXL range is designed to handle a variety of tasks across industries such as construction, automotive, and general metal fabrication. Its ability to handle both straight and box folding in a single program makes it highly versatile for complex folding operations. The high divided tools are particularly suited for box and panel work, allowing intricate designs and precise finishes.

Whether fabricating custom components or managing large-scale production, the EXL folders adapt to diverse operational demands, ensuring reliable performance. With their ability to automate complex sequences, they are ideal for both small-scale and high-volume production environments.

Built for Long-Term Value

Durability is a hallmark of the EXL CNC folders. The robust construction minimises deflection during operation, even under heavy loads, ensuring consistent precision. Servo motor-powered axes further enhance reliability, providing smooth movements and reducing wear over time. These features result in lower maintenance costs and a longer machine lifespan, offering excellent value for investment.

Additionally, the reduction in manual intervention and labour requirements makes the EXL range a cost-effective solution for businesses looking to streamline their folding operations.

Conclusion

The Morgan Rushworth EXL CNC folders deliver advanced functionality, precision, and efficiency, making them a standout choice for modern metal fabrication. With features such as the rotating upper beam, integrated back gauge and support table, and advanced CNC controls, these machines simplify complex folding operations while enhancing productivity.

Whether you’re folding large panels or intricate box shapes, the EXL range offers versatility and reliability to meet the demands of various industries. Backed by durable construction and innovative design, these folders provide long-term value and a strong return on investment. To learn more about the Morgan Rushworth EXL range and how it can transform your production processes, contact us today.