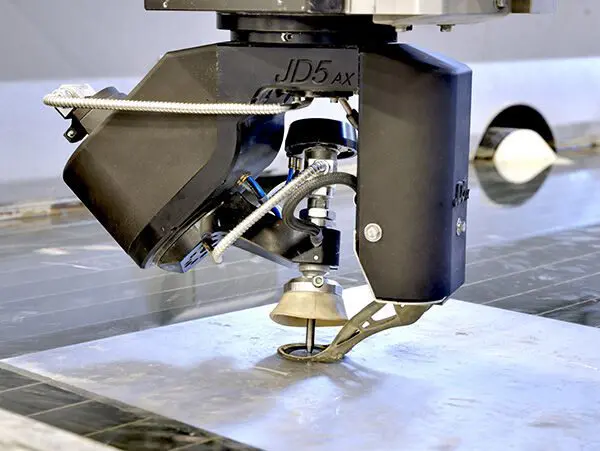

CMS Smartline Waterjet Cutter

The CMS Smartline Waterjet Cutter provides an accurate and cost-effective entry-level solution for waterjet cutting. Designed to enhance operating efficiency, it redefines industry standards while upholding CMS’s reputation for exceptional construction and working quality. Its compact and innovative design ensures versatility and reliability.

Equipped with all the safety and performance features typical of CMS waterjet machines, the Smartline offers an ideal combination of precision and efficiency. Whether for small workshops or larger operations, it delivers consistent results with minimal setup, making it an excellent choice for businesses seeking reliable waterjet cutting technology.

| Model | CMS Smartline | CMS Proline | ||

| Size | 2040 | 1730 | 2040 | |

| X Axis | mm | 4,000 | 4,250 | |

| Y Axis | mm | 2,000 | 2,000 | |

| Z Axis | mm | 250 (3-Axis) / 150 (5-Axis) | 300 (3-Axis) / 200 (5-Axis) | |

| B Axis (5 Axis Only) | ° |

±60 |

±62 | |

| C Axis (5 Axis Only) | N/A | Infinite | ||

| XY Axis Rapid Speed | mm/min | N/A | 40,000 | |

| Rest Surface | mm | 4150 x 2080 | 3700 x 2025 | 4650 x 2050 |

| Workable Load Capacity | kg/m2 | 500 | 1,000 | 1,000 |

| Position Accuracy | mm | +/- 0.1 | +/- 0.035 | |

| Position Repeatability (BS) | mm | +/- 0.05 | +/- 0.025 | |

| Installed Power | HP | 60 | 60 | |

| Overall Dimensions | mm | 5,595 x 7,400 x 4,000 | 7,152 x 3,183 x 4,1049 | 8,158 x 3,483 x 3,900 |

| Weight (Empty) | kg | 3,900 | 4,000 | 8,000 |

Features

- Mobile control panel with laptop

- New Z axis strokes up to 350mm 3 axis, up to 150mm 5 axis

- Easyjet DDX CAD/CAM Software

- Electronic hopper for abrasive automatic monitoring with sensors for cutting parameters automatic control

- Probe system for consistent cutting heights

- Integrated electric cabinet in the tank frame for a reduced footprint

- Bellows for X-Axis and labyrinth panels for Y-Axis to protect the linear guides and racks from water, dust and abrasives

- Aluminium cast uprights, welded steel bridge with reinforcement ribs

- Automatic lubrication of all axes

Options

- 60Hp Jetpower Evo Pressure Intensifier

- 4139 / 6200 Technocut Greenjet Evo Pressure Intensifier

- 21.5″ Touch Screen control panel on a mobile trolley

- Work area cleaning system

- Air conditioning for electrical cabinet

- Cross-Laser pointer

- Anti-collision feeler

- Drilling Unit

- Automatic hose reel

- Electronic Hopper

- Dredging system for “no maintenance” abrasive removal

CMS Smartline Waterjet Cutter

The CMS Smartline Waterjet Cutter is an entry-level yet high-performing solution for businesses seeking precision, efficiency, and cost-effectiveness in waterjet cutting. Designed to improve operational efficiency while maintaining CMS’s hallmark quality, the Smartline sets a new benchmark in the industry. Its compact and innovative design offers safety and performance features typical of CMS waterjet machines, ensuring consistent and reliable operation.

Entry-Level Excellence

The CMS Smartline Waterjet is ideal for businesses new to waterjet cutting or those looking to expand their capabilities without a significant upfront investment. It provides an accessible and cost-effective solution without compromising on performance. The machine’s robust construction and advanced engineering ensure durability and accuracy, making it a reliable choice for various industries.

Compact and Innovative Design

A standout feature of the Smartline Waterjet is its compact footprint, which makes it suitable for workshops with limited space. Despite its smaller size, the machine delivers exceptional cutting performance, maintaining CMS’s reputation for excellence. The design integrates advanced technology into a user-friendly format, allowing businesses to maximise their productivity without overhauling their workspace.

Precision and Performance

Equipped with state-of-the-art cutting technology, the CMS Smartline offers:

- High cutting accuracy: Achieves intricate and detailed cuts on a variety of materials.

- Consistent performance: Delivers reliable results, even in demanding production environments.

- Material versatility: Cuts a wide range of materials, including metals, plastics, glass, and composites.

These features make the Smartline Waterjet a versatile and indispensable tool for businesses requiring precision and adaptability.

Enhanced Efficiency

The CMS Smartline Waterjet is engineered to optimise operational efficiency. Its advanced systems reduce waste, improve material utilisation, and minimise downtime. Key efficiency features include:

- Streamlined operation: User-friendly controls simplify setup and operation, reducing training time for operators.

- Energy-efficient technology: Lowers operational costs by reducing power consumption.

- Minimal maintenance requirements: High-quality components ensure long-term reliability with minimal upkeep.

By focusing on efficiency, the Smartline Waterjet helps businesses achieve more with less, making it a cost-effective investment.

Safety and Reliability

Safety is a top priority in the design of the CMS Smartline Waterjet. The machine incorporates numerous safety features to protect operators and ensure smooth operation, including:

- Fully enclosed cutting area: Prevents accidental exposure to high-pressure water streams and debris.

- Advanced monitoring systems: Ensure consistent performance and alert operators to potential issues.

- Robust construction: Minimises vibrations and enhances stability during operation.

These features ensure a safe and secure working environment, giving businesses peace of mind while using the machine.

Applications Across Industries

The versatility of the CMS Smartline Waterjet makes it suitable for a wide range of industries, including:

- Aerospace: Cutting high-precision components for aircraft and spacecraft.

- Automotive: Producing parts and prototypes with intricate designs.

- Architecture and design: Creating detailed patterns and shapes in stone, glass, and metal.

- Manufacturing: Handling various materials for custom fabrication and production.

Its adaptability ensures that the Smartline Waterjet meets the diverse needs of modern industries.

Cost-Effective Operation

The CMS Smartline Waterjet is designed with cost efficiency in mind. Its advanced features and durable construction reduce operating and maintenance costs, providing a strong return on investment. Key cost-saving benefits include:

- Reduced material waste: Precise cutting minimises scrap material.

- Energy efficiency: Low power consumption reduces operational expenses.

- Longevity: High-quality components extend the machine’s lifespan, reducing the need for replacements.

These advantages make the Smartline Waterjet an economical choice for businesses looking to optimise their production processes.

Supporting Business Growth

The CMS Smartline Waterjet is more than just a cutting machine; it is a tool for growth. By providing reliable performance, advanced features, and cost-effective operation, it enables businesses to scale their operations and meet increasing production demands. Its versatility and precision make it a valuable asset for companies aiming to expand their capabilities and enter new markets.

Conclusion

The CMS Smartline Waterjet Cutter combines precision, efficiency, and safety in a compact and innovative design. As an entry-level solution, it delivers unparalleled value by maintaining CMS’s renowned quality standards while offering cost-effective operation. Its versatility and reliability make it suitable for a wide range of industries, ensuring it meets the demands of modern manufacturing and fabrication.

Whether you’re new to waterjet cutting or looking to enhance your existing capabilities, the CMS Smartline Waterjet is a dependable and efficient choice. Invest in the Smartline today and experience the benefits of precision cutting, operational efficiency, and long-term value.