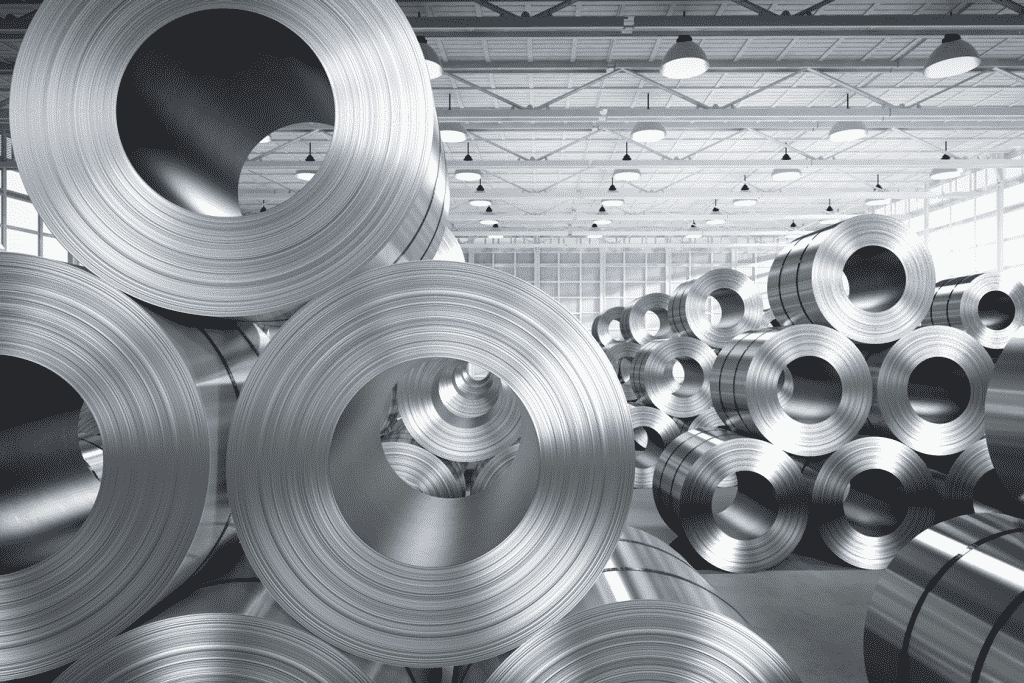

Alloys, in their most basic form are mixtures; mixtures of different metals or even metals and other elements, with the aim of changing the alloy’s properties. These properties can vary depending on their intended purpose. A certain alloy might offer greater strength, ductility, flexibility or durability when compared to the base metal and they are used a lot, common alloys used today include steel, stainless steel, aluminium, titanium or bronze.

The key strengths of an alloy are its ability to strengthen metals while maintaining the best of that metal’s properties, while at the same time also reducing costs. Let’s take iron for example, a metal with impressive durability and strength. When you create an alloy of iron and carbon you have steel; stronger than iron yet much lighter, making it a highly efficient building material for everything from tall buildings to ships, weapons and general metal fabrication projects.

Another type of metal alloy is aluminium alloy where the predominant metal; aluminium is combined with other metals such as magnesium, copper or zinc. Aluminium is more versatile and adaptable from a manufacturing point of view than many other metals making it a popular choice for architectural and industrial fabrication projects thanks to its lightness and durability.

Bronze

Incredible toughness and impressive durability make this alloy ideal for things such as rotors, turbines and coins. An alloy of copper, it has a low melting point and is heavier than steel and tends not to oxidise beyond the surface layer.

Brass

Like bronze, brass is an alloy of copper, but with zinc added to the base metal. Rigid and strong, brass is perfect for heavy duty nuts and bolts, marine engineering applications and domestic fittings as well as valves and seawater pipes. It is also a material with good acoustic properties making it suitable for musical instruments.

Stainless steel

Stainless steel is, in many ways an alloy of an alloy, being made from steel (carbon and iron) along with chromium, aluminium or other elements to create a metal that is highly resistant to corrosion. Stainless steel is available in many different grades and incredibly versatile, stainless steel has countless uses; from kitchenware and fittings to blades and surgical instruments.

Titanium

High tensile strength and durability at extreme temperatures makes titanium ideal for the aerospace industry and maritime engineering, as well as dental implants and jewellery. It is stronger than aluminium and highly corrosion resistant.

When you consider which metal alloy to use, then application is everything. Careful thought needs to be put into things like weathering, durability, tensile strength and malleability and much more. Durable alloys might be more expensive, but the components may last considerably longer. As always if help and advice are needed on alloys and the machines to work with them, get in touch today.

Published 19th November 2018