Morgan Rushworth HSP Hydraulic Punching Machine 415V

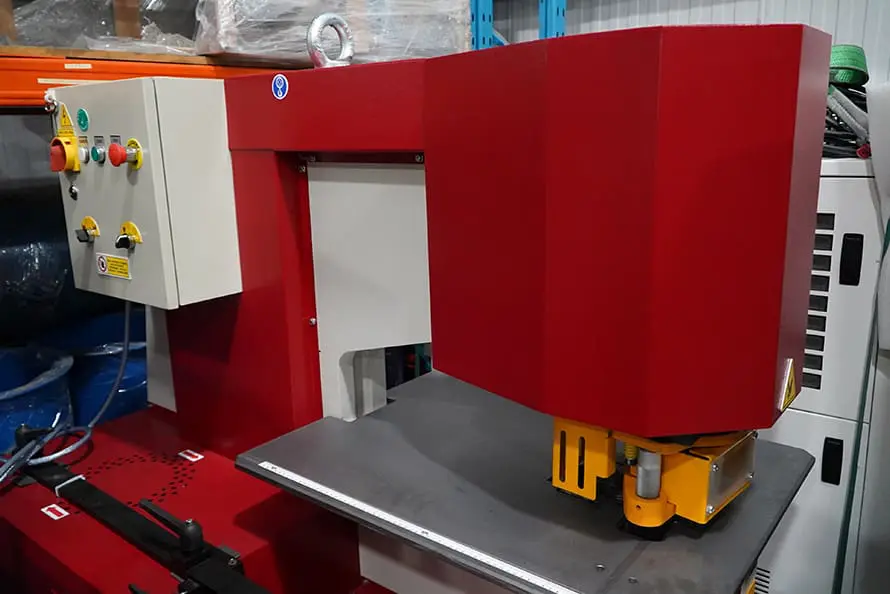

The Morgan Rushworth hydraulic punching machines come in models ranging from 70 to 175 tonnes of capacity, all featuring a standard 625mm deep throat. Each machine includes a heavy-duty support table with adjustable backstop, a universal die holder for punching plate, flat bar, angle iron, and the flanges of channels and beams. Double-ended configurations are also available for enhanced functionality.

Standard machines can punch up to 57mm in diameter without extra equipment, with a removable front section on the support table to punch angle iron leg down. Additional options include bar bending, sheet bending, and corner notching for greater versatility.

| MODEL | HSP 70 | HSP 95 | HSP 125 | HSP 175 | |||||

| STOCK CODE | M9007 | M9008 | M9009 | M9010 | |||||

| Punching | |||||||||

| Diameter X Maximum Thickness | mm | 26 x 20 | 33 x 20 | 34 x 26 | 40 x 32 | ||||

| Maximum Diameter X Thickness | mm | 57 x 10 | 57 x 12 | 57 x 16 | 57 x 22 | ||||

| Stroke Length | mm | 55 | 80 | 80 | 80 | ||||

| Throat Depth | mm | 625 | 625 | 625 | 625 | ||||

| Largest Hole Diameter – Standard | mm | 57 | 57 | 57 | 57 | ||||

| Largest Hole Diameter (Optional) | mm | 110 | 110 | 110 | 110 | ||||

| Tube Notch (Optional) | |||||||||

| Maximum Outside Diameter | mm | 83 | 108 | 108 | 165 | ||||

| Bending (Optional) | |||||||||

| Bar Bending – Maximum Capacities | mm | 200 x 15 | 250 x 20 | 250 x 22 | 250 x 25 | ||||

| Sheet Bending – Maximum Capacities | mm | 500 x 3 | 500 x 3 | 700 x 3 | 700 x 4 | ||||

| Corner Notching (Optional) | |||||||||

| Maximum Capacity | mm | 250 x 6 | 250 x 6 | 250 x 6 | 250 x 6 | ||||

| Technical Data | |||||||||

| Motor Power | kW | 5.5 | 7.5 | 11 | 11 | ||||

| Length | mm | 1600 | 1850 | 2000 | 2700 | ||||

| Width | mm | 900 | 950 | 950 | 1120 | ||||

| Height | mm | 1800 | 1920 | 1970 | 2160 | ||||

| Weight | kg | 2440 | 3270 | 3760 | 5720 |

Features

- Full stroke adjustment

- Low power inching

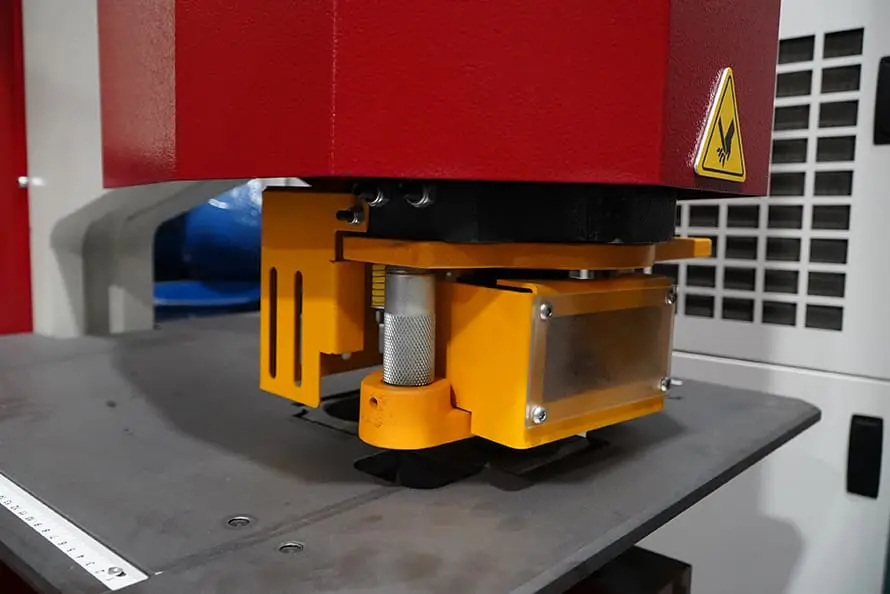

- Punch table with multipurpose bolster

- Removable table block for overhang channel/beam flange punching

- Low maintenance

- Overload relief on hydraulic system

- Swing away punch stripper unit

- Easy change punch holder

- Punch table with guides

- Work station guard

- Magnetic based working lamp

Options

- Large hole attachments

- Bending units

- Special tooling & accessories

Morgan Rushworth Hydraulic Punching Machines

The Morgan Rushworth hydraulic punching machines are a robust and versatile solution for a wide range of metalworking applications. Available in models with capacities ranging from 70 to 175 tonnes, these machines are designed to handle even the most demanding tasks. Each model is equipped with a 625mm deep throat as standard, providing ample space for punching larger workpieces with ease. This combination of power and precision ensures these machines are well-suited to meet the needs of fabricators and manufacturers alike.

Standard Features

Each Morgan Rushworth punching machine comes with an impressive array of standard features, making them a complete solution straight out of the box. The heavy-duty support table, complete with an adjustable backstop, ensures accurate and repeatable punching. Additionally, a universal die holder is included, enabling efficient punching of various materials, including plate, flat bar, angle iron, and the flanges of channels and beams. The inclusion of these features ensures users can start working with minimal setup or additional purchases.

One standout feature is the ability to punch up to 57mm diameter holes without requiring additional equipment. This capability makes these machines a versatile choice for workshops looking to handle a broad spectrum of tasks. Furthermore, the front section of the support table can be removed, allowing operators to punch angle iron with the leg positioned down. This design not only enhances flexibility but also simplifies complex punching operations.

Double-Ended Configuration

For those requiring additional functionality, Morgan Rushworth offers double-ended configurations for their hydraulic punching machines. This feature allows users to perform multiple operations simultaneously, significantly improving productivity. The double-ended design is ideal for high-volume production environments, where time and efficiency are critical factors.

Versatile Applications

Morgan Rushworth punching machines are designed to handle a wide variety of applications, making them a valuable asset in any workshop. Their ability to punch different materials, shapes, and sizes ensures they can adapt to the diverse needs of users. Whether you are working with structural steel, flat bar, or specialised profiles, these machines provide the performance and precision required.

The universal die holder further extends their versatility, enabling users to switch between different punching tasks quickly and easily. This adaptability makes the Morgan Rushworth range a preferred choice for industries such as construction, manufacturing, and metal fabrication.

Optional Features

In addition to their comprehensive standard features, Morgan Rushworth hydraulic punching machines offer a range of optional enhancements to further expand their capabilities. These include:

- Bar Bending: Add bar bending capabilities to handle a variety of bending tasks with precision.

- Sheet Bending: Incorporate sheet bending for increased functionality and flexibility in sheet metal work.

- Corner Notching: Perform precise corner notching operations to meet specific fabrication requirements.

These optional features make the machines even more versatile, allowing users to customise them according to their unique needs and applications.

Durability and Reliability

Built with durability in mind, Morgan Rushworth punching machines are designed to withstand heavy-duty use in demanding environments. Their robust construction ensures a long service life, even under continuous operation. This reliability not only reduces downtime but also ensures a consistent output, making them a cost-effective investment for any business.

The machines are also designed with operator safety and convenience in mind. The adjustable backstop and removable front section simplify setup and operation, while the sturdy support table provides a stable work surface. Comprehensive safety features further enhance the user experience, ensuring safe and efficient operation at all times.

Why Choose Morgan Rushworth?

Morgan Rushworth has a long-standing reputation for manufacturing high-quality metalworking machinery. Their hydraulic punching machines exemplify this commitment to excellence, offering a perfect balance of power, precision, and reliability. With a focus on user-friendly design and robust construction, these machines are built to meet the demands of modern workshops.

Whether you need a machine for punching, bending, or notching, the Morgan Rushworth range provides a comprehensive solution that can be tailored to your specific requirements. Their combination of standard features and optional enhancements ensures maximum versatility, making them an invaluable addition to any metalworking operation.

Conclusion

The Morgan Rushworth hydraulic punching machines deliver exceptional performance and versatility, making them a top choice for fabricators and manufacturers. With models ranging from 70 to 175 tonnes, they cater to a wide range of applications, from punching large holes to intricate notching tasks. Standard features such as the universal die holder and adjustable support table provide users with the tools they need to tackle complex projects efficiently.

For those looking to enhance their capabilities further, the available optional features offer additional functionality, ensuring these machines can adapt to the ever-changing needs of the industry. With their robust construction, user-friendly design, and proven reliability, Morgan Rushworth punching machines are an excellent investment for businesses seeking to improve productivity and precision in their operations.

Don’t Let Downtime Derail You: The Importance of Maintenance

3rd April 2025 by Dave Hargest

Quick Start – Morgan Rushworth HST 95 Steelworker

12th November 2024 by Dave Hargest

How to Safely Remove and Install A Punch & Die on a Morgan Rushworth Steelworker

21st July 2017 by Clare Harris

HSP CNC Punch Vs Traditional Steelworker

3rd April 2017 by Clare Harris

How to Adjust the Stroke Limit Switches on a Steelworker

28th June 2016 by Clare Harris

How to Adjust the Material Clamping System on a Steelworker FAQ

15th June 2016 by Clare Harris

Related Case Studies

Coleg Gwent – Machinery for the next generation

14th November 2023 by Dave Hargest

Coleg Gwent is Wales' largest further education and one of the best-performing colleges, delivering a wide range of part-time and full-time academic and vocational courses to over 16,000 students annually... More

Pembrokeshire College adds to their collection

26th April 2023 by Dave Hargest

Pembrokeshire College is a provider of a wide range of Post-16 study options in South-West Wales, including an impressive set-up for Engineering based courses with their new Welding and Fabrication.. More

Facade and Cladding Solutions expand and upgrade their machinery

22nd June 2022 by Dave Hargest

Our customer Facade and Cladding Solutions spoke to us about their experiences buying a range of machines from us here at Selmach, including a Press Brake, Guillotine, Steelworker and Corner.. More

Ornamental blacksmith Stow Forge takes it easy with the Morgan Rushworth Steelworker

6th August 2020 by Clare Harris

Stow Forge is a family-owned ornamental blacksmiths and metal fabrication business. They are based in Essex and provide Colchester, Chelmsford and the surrounding areas with high quality hand-crafted domestic products.. More

T&M Buildings go better & faster by upgrading to the Morgan Rushworth Steelworker

6th July 2020 by Clare Harris

T & M Buildings specialises in the design, fabrication, supply and erection of bespoke steel frames for farm, agricultural and industrial clients, covering Devon and the surrounding areas. When they.. More