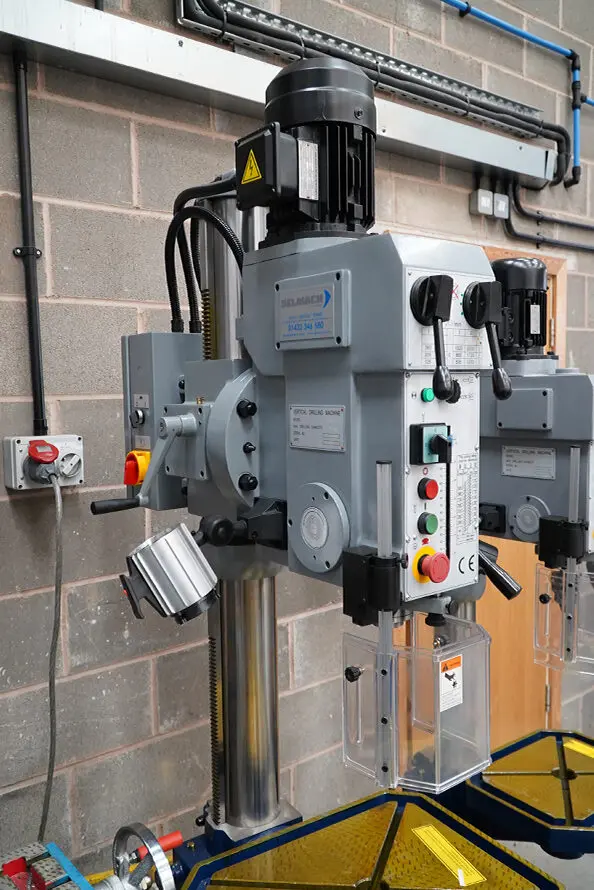

Meyer SR32 Geared Head Drilling Machine 415v

The Meyer SR32 Geared Head Drilling Machine is a reliable and robust solution for industrial drilling applications. Known for its heavy-duty construction and precision engineering, it upholds Meyer’s reputation for durability and performance. Manufactured with high-quality components and assembled to exacting standards, the SR32 ensures consistent and reliable operation in demanding environments.

An upgrade from the SR25 model, the SR32 features an increased drill bit capacity and a built-in coolant system. These enhancements enable the machine to handle larger and more complex drilling tasks with ease, making it an invaluable tool for workshops and production lines.

| MODEL | SR25 | SR32 | SR32AE | SR50VAE | SR70TAE | |

| STOCKCODE | 18046 | 18041 | 18042 | 18066 | 18070 | |

| Drilling Capacity | mm | 25 | 32 | 32 | 50 | 70 |

| Tapping Capacity | M18 | M22 | M22 | M30 | M50 | |

| Column dia | mm | 95 | 120 | 120 | 180 | 220 |

| Spindle Taper | MT no | 3 | 4 | 4 | 4 | 5 |

| Motor | Kw | 0.75 | 1/1.2 | 1/1.2 | 3 | 5.5 |

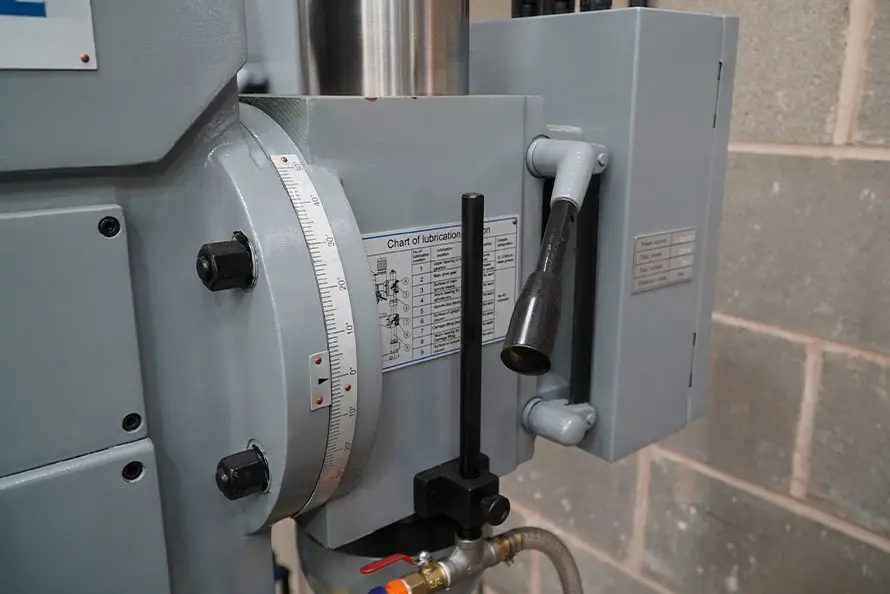

| Speeds | rpm | 125 – 2825 (stepped) | 125 – 3030 (stepped) | 125 – 3030 (stepped) | 50 – 2200 (variable) | 38 – 1230 (Variable) |

| Spindle Stroke | mm | 110 | 160 | 160 | 240 | 270 |

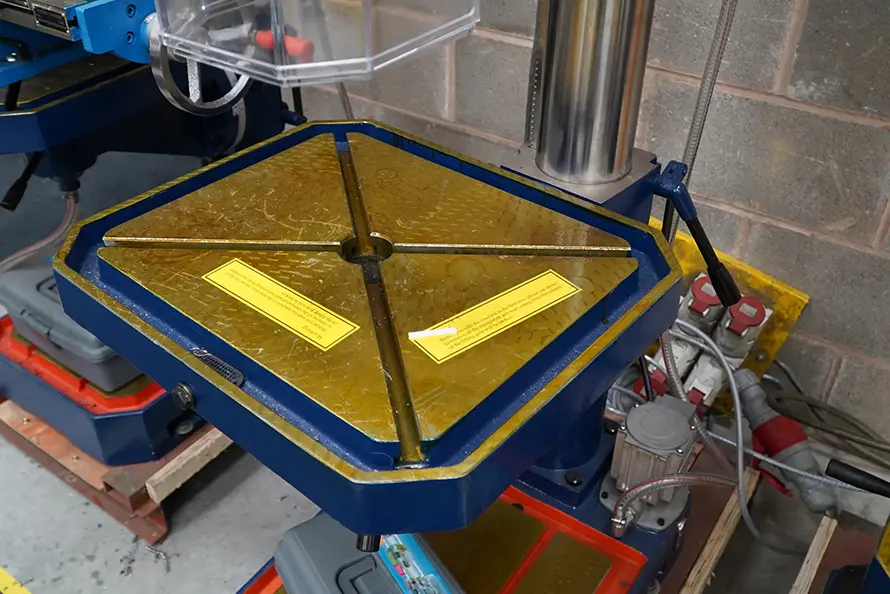

| Work Table | mm | 350 x 400 | 500 x 420 | 500 x 420 | 580 x 460 | 600 x 600 |

| Base Plate | mm | 340 x 340 | 330 x 330 | 320 x 320 | 440 x 450 | 636 x 490 |

| Throat | mm | 240 | 320 | 320 | 360 | 420 |

| Coolant | No | Standard | Standard | Standard | Standard | |

| Auto Feed | No | No | Yes | Yes | Yes | |

| Tapping Facility | No | No | Yes | Yes | Yes | |

| Length | mm | 700 | 830 | 830 | 980 | 1220 |

| Width | mm | 450 | 510 | 510 | 650 | 650 |

| Height | mm | 1900 | 2180 | 2180 | 2370 | 2820 |

| Weight | Kg | 400 | 470 | 510 | 655 | 980 |

*Capacities are given for 250 N/mm plate yielding strength

Features

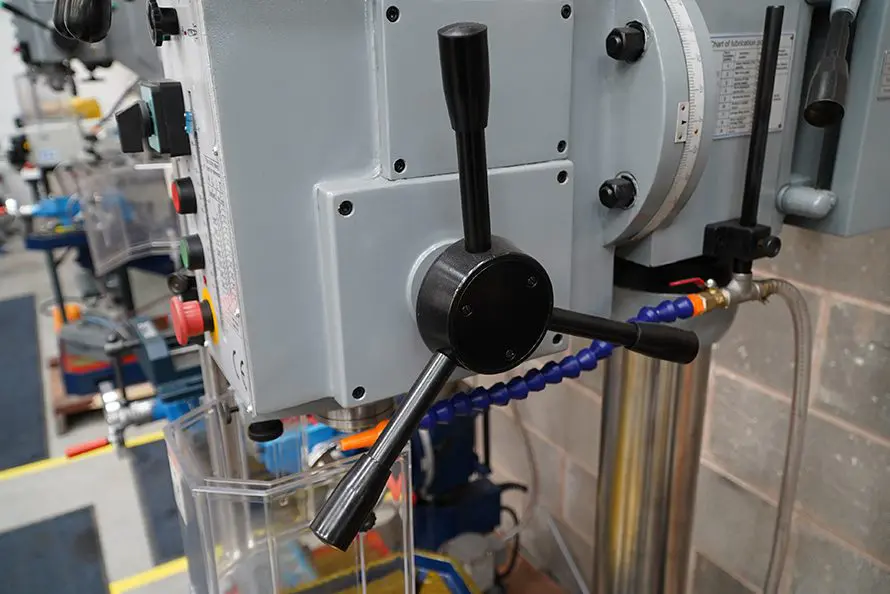

- Geared head

- Exceptional heavy construction

- Large work tables

- Auto tool release

- Eye shield with interlock switch

- Low voltage lamp

- Rise and fall table

- Rise and fall head

- Forward and reverse

- Coolant

Options

- Morse Taper to Weldon Adaptor

- Drill Press Vice: 18009

- Universal Cross Table: 18047

- DC Injection Brake

- Dead Man Foot Pedal

- Foot Pedal Emergency Stop

Introduction to the SR32 Geared Head Drill

The Meyer SR32 Geared Head Drilling Machine 415v is a powerful and reliable solution designed to handle demanding industrial drilling tasks. Renowned for its robust construction and precision engineering, the SR32 exemplifies Meyer’s commitment to delivering high-quality, long-lasting machinery. Built with premium components and assembled to the highest standards, this machine has earned its place as a trusted tool for workshops and production lines worldwide.

Exceptional Build Quality and Reliability

The Meyer SR32 is engineered to withstand rigorous use, making it ideal for heavy-duty industrial environments. Its durable construction ensures consistent operation, even under the most challenging conditions. Meyer’s focus on quality and craftsmanship is evident in every detail of the SR32, from its sturdy frame to its precision components. This commitment to excellence has solidified Meyer’s reputation for producing machines that deliver reliable performance over the long term.

Key Features of the Meyer SR32

The SR32 stands out within the Meyer range thanks to its advanced features, which include:

- Increased Drill Bit Capacity: A step up from the SR25 model, the SR32 accommodates larger drill bits, allowing for more versatility in applications.

- Built-In Coolant System: Enhances operational efficiency by reducing heat generation, protecting both the tool and the workpiece, and extending tool life.

- Heavy-Duty Construction: Built to last, the SR32 is designed to handle intense workloads with ease.

- Precision Engineering: Ensures accurate and consistent drilling results, making it suitable for a wide range of industrial tasks.

The Next Step Up in Performance

The Meyer SR32 is an upgrade from the popular SR25 model, offering enhanced capabilities to meet the evolving needs of modern industries. The increased drill bit capacity expands the range of tasks that can be performed, while the addition of a coolant system ensures smooth and efficient operation during prolonged use. These improvements make the SR32 an excellent choice for businesses looking to boost productivity and maintain high standards of precision.

Applications Across Industries

The versatility of the Meyer SR32 makes it suitable for a wide array of industrial applications, including:

- Metal Fabrication: Perfect for drilling and tapping in sheet metal and other metal components with precision.

- Automotive Manufacturing: Supports the creation of accurate holes and threads for automotive parts.

- Construction: Ideal for crafting structural components with consistency and efficiency.

- General Engineering: A dependable tool for various drilling tasks in engineering workshops.

This adaptability ensures that the SR32 meets the diverse needs of industries worldwide.

Benefits of the Meyer SR32

Investing in the SR32 provides a range of advantages, including:

- Improved Productivity: The increased drill bit capacity and built-in coolant system enable faster and more efficient operation.

- Enhanced Precision: Precision engineering ensures consistent and accurate results, reducing errors and material waste.

- Durability: High-quality construction ensures the machine’s long-term reliability, even in demanding industrial settings.

- Versatility: Suitable for a variety of materials and applications, making it a valuable addition to any workshop.

- Ease of Maintenance: Straightforward maintenance requirements and readily available replacement parts ensure the machine remains in top condition.

Meyer’s Commitment to Quality

Meyer has built a strong reputation for producing reliable and innovative industrial machinery, and the SR32 is no exception. Each machine is meticulously designed and tested to ensure it meets the highest standards of performance and durability. This dedication to quality has made Meyer a trusted name among professionals, with machines that consistently exceed customer expectations.

Maintenance and Longevity

The Meyer SR32 is designed for durability and ease of maintenance. Regular upkeep ensures optimal performance and extends the machine’s lifespan, making it a cost-effective investment for businesses. The inclusion of a built-in coolant system not only improves operational efficiency but also reduces wear and tear, further enhancing the machine’s longevity.

Conclusion

The Meyer SR32 Geared Head Drilling Machine 415v is a robust, versatile, and high-performance solution for industrial drilling applications. With its increased drill bit capacity, built-in coolant system, and precision engineering, the SR32 is an upgrade that delivers superior results. Whether in metal fabrication, automotive manufacturing, construction, or general engineering, this machine offers the reliability and efficiency needed to excel in demanding environments. For businesses seeking a dependable and advanced drilling solution, the Meyer SR32 is an investment that ensures long-term satisfaction and exceptional performance.