We get to grips with what guillotine is best for your business.

Mechanical or Hydraulic?

First, think about the capacity you need. We have guillotines that cut from a metre to 5-metre wide plate and anything from 0.1mm up to 25mm thick plate. The material you want to cut will determine the type of machine that is best for you.

Your next consideration will be whether you need a mechanical or a hydraulic machine. As Bruce explains in the video, both have their advantages. But as a starter, a mechanical guillotine can only cut thicknesses up to 4-5mm, whereas the hydraulic machines have the cutting capacity of cutting up to 25mm material.

“Hydraulic guillotines have the edge when it comes to capacity”

Mechanical guillotine

When it comes to simplicity the mechanical option has the edge. Not only is it of simpler and smaller construction than its hydraulic counterpart, the mechanical machine is quieter, and greener too as there’s no need for hydraulic oil. If you’re cutting light sheet metal material up to 4mm the mechanical machine is probably your best option as they have a very fast cut per minute rate.

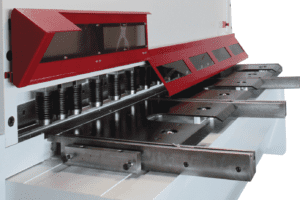

Swing beam hydraulic guillotine

The hydraulic swing beam guillotine is well priced with great capacities. The swing beam option is ideally suited for materials over 1.5mm up to a maximum of 20mm. These models have a fixed rake angle which is designed to cope with the heavier materials. This is by far the most popular option among our clients.

Variable rake hydraulic guillotine

If you need to cut a range of thicknesses, then a variable rake hydraulic guillotine would be your best option. The variable rake allows more cutting variation especially when you’re cutting small thin strips. The variable rake allows you to, as the name would suggest, to vary the rake on the top beam as it’s cutting, which reduces the likelihood of the cut part twisting. This design is likely to offer the most accurate cut, but as you’d expect, it is also the most expensive.

Additional extras

There are also many optional extras might you need to make cutting life that little bit easier. If you’re cutting a small strip off a large sheet where the majority of the material is out the front of the machine, then a longer squaring arm or support arms would be a good option. These optional extras will eliminate the material bowing issue at the front of the machine.

Next, are you cutting many pieces? Then perhaps a conveyer and a stacker are good options for you. The downside is that these are not cheap options and can slow down the cut-per-minute rate.

We strongly recommend the Front Light Finger Guard system as it gives you great visibility and helps you to see exactly where the material is being cut.

You also might benefit from the motorised blade gap option if you are cutting many different thicknesses. As we know accurate blade gap adjustment will ensure a good sheared edge on all thicknesses.

The optional extras you choose will very much depend on what you are cutting.

So, which of these machines will have the greatest impact on your productivity? We have an impressive range of high quality guillotines available to suit your purposes and with our trained engineers on hand with expert help, training and advice, you can be sure to find the best machine for your operation.

For more information on our range of Guillotines or to see one in action for yourself; click, tap or call us on +44 (0)1432 346 580, email sales@selmach.com or get in touch via our website.

Published 26th October 2018