Morgan Rushworth BHGS Hydraulic Swing Beam Guillotine

The powerful BHGS range of hydraulic swing beam sheet metal guillotines are equipped with a high visibility front guard design consisting of a fixed guard with windows. All machines are fitted with stainless steel quality cutting blades as standard, giving flexibility to cut a range of materials without detriment to blade life.

The user friendly Cybtouch 8 NC controller ensures accurate cutting with precision back gauge setting and the facility to store complete cutting lists including length and quantity. For longer lengths an automatic swing away backgauge is standard.

| CUTTING LENGTH | CUTTING CAPACITY (45 kg/mm2) | CUTTING CAPACITY (70 kg/mm2) | CUTTING ANGLE | STROKES PER MINUTE | No. OF HOLD DOWNS | MAIN MOTOR | BACKGAUGE MOTOR | BACKGAUGE TRAVEL | OIL CAPACITY | TABLE LENGTH | TABLE HEIGHT | TRANSPORT WIDTH | MACHINE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT | ||

| MODEL | STOCK CODE | mm | kw | kw | mm | lt | _A mm | _G mm | _C mm | _C+E mm | _L mm | _C+D+E mm | _H mm | kg | |||||

| BHGS 3100/6 NC | M1062 | 3060 | 6 | 4 | 1.5 | 18 | 17 | 11 | 0.37 | 1000 | 170 | 3340 | 800 | 1600 | 2600 | 3770 | 3100 | 1825 | 7000 |

| BHGS 3100/10 NC | M1063 | 3060 | 10 | 6 | 2 | 12 | 17 | 22 | 0.37 | 1000 | 170 | 3420 | 800 | 1775 | 2775 | 3850 | 3275 | 1850 | 9200 |

| BHGS 3100/13 NC | M1064 | 3060 | 13 | 8 | 2.4 | 12 | 17 | 30 | 0.37 | 1000 | 220 | 3450 | 900 | 1985 | 2985 | 3880 | 3485 | 2060 | 11500 |

| BHGS 3100/16 NC | M1065 | 3060 | 16 | 10 | 2.7 | 7 | 17 | 30 | 0.55 | 1000 | 220 | 3410 | 900 | 2150 | 3150 | 3840 | 3550 | 2230 | 15500 |

| BHGS 3100/20 NC | M1066 | 3060 | 20 | 13 | 3 | 7 | 18 | 37 | 0.55 | 1000 | 280 | 3470 | 900 | 2140 | 3140 | 3900 | 3540 | 2440 | 19600 |

| BHGS 4100/10 NC | M1067 | 4060 | 10 | 6 | 2 | 10 | 23 | 22 | 0.37 | 1000 | 170 | 4370 | 800 | 1975 | 2975 | 4800 | 3375 | 1910 | 13000 |

| BHGS 4100/13 NC | M1068 | 4060 | 13 | 8 | 2.2 | 8 | 23 | 30 | 0.37 | 1000 | 220 | 4400 | 900 | 1975 | 2975 | 4830 | 3375 | 2160 | 16100 |

Features

- CybTouch 8 NC Controller

- Fast and powerful back gauge with 750mm travel

- Automatic swing away backgauge feature

- Stainless steel cutting blades with multiple cutting edges

- Cutting line illumination with shadow wire

- Cutting length stroke adjustment for narrower sheets reducing cutting time

- Digital stroke counter

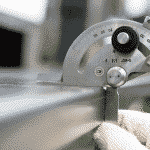

- Easy blade gap adjustment system from single point

- Powerful hydraulic material hold downs prevent sheet sliding during cutting

- Front guards with windows for excellent visibility of cutting area

- Support table with roller bearings

- 1000mm front squaring arm with tee slot and flip stop

- Front support arms with 1000mm length

- Foot pedal available for single or continuous cutting

- One-piece honed and chrome plated double acting powerful cylinders

- Rear photo-cell guards

Options

- 1000mm backgauge travel in lieu of standard 750mm

- Powered blade gap adjustment

- Pneumatic rear sheet support system

- Tee Slot, flip stop & rule on front support arms

- Angle gauge

- 1 metre lift up finger guard with interlock switch

- Front CE light guards in lieu of standard fixed front guards

- Laser cutting line

- Longer squaring arms and support arms

Morgan Rushworth BHGS Hydraulic Swing Beam Guillotine: Precision and Durability for Metal Cutting

The Morgan Rushworth BHGS hydraulic swing beam guillotine range offers a high-performance solution for precise sheet metal cutting. Designed to handle a variety of materials with accuracy and efficiency, these machines are an ideal choice for workshops and production facilities. With a focus on safety, user-friendliness, and long-lasting quality, the BHGS range ensures consistent and reliable results for demanding professionals.

High-Visibility Front Guard for Enhanced Safety

A standout feature of the BHGS range is its high-visibility front guard design, which combines safety with practicality. This innovative system uses a fixed guard with integrated windows, providing a clear view of the cutting area. Unlike traditional guards that can obstruct visibility, this design allows operators to monitor the material closely while maintaining safety. This combination of protection and precision ensures higher-quality cuts and improves the overall user experience.

Stainless Steel Blades for Reliable Performance

All BHGS models are equipped with stainless steel cutting blades as standard, ensuring exceptional durability and performance. These high-quality blades maintain their sharpness over extended periods, enabling efficient cutting of various materials without frequent replacements. This durability reduces maintenance costs and increases machine efficiency. Additionally, the flexibility of the stainless steel blades allows for the processing of a wide range of materials, making the BHGS range a versatile choice for diverse cutting applications.

Cybtouch 6 NC Controller for Advanced Precision

The BHGS guillotines feature the Cybtouch 6 NC controller, a user-friendly interface designed to streamline the cutting process. This advanced control system enables operators to precisely set back gauge dimensions and programme complete cutting lists, including length and quantity. Ideal for repeat production runs, the NC controller simplifies setup, reduces errors, and ensures consistent results. By saving cutting parameters for recurring tasks, this feature enhances productivity and efficiency, making it a practical tool for modern workshops.

Automatic Swing-Away Back Gauge for Longer Sheets

For handling longer sheets, the BHGS guillotines include a standard automatic swing-away back gauge. This feature allows for seamless accommodation of larger workpieces without the need for manual adjustments. When not required, the back gauge automatically moves out of the way, reducing operator effort and enabling smooth handling of long materials. This thoughtful design element enhances the machine’s versatility and efficiency, ensuring optimal performance in a variety of cutting scenarios.

Hydraulic Swing Beam Design for Clean, Accurate Cuts

The BHGS guillotines utilise a hydraulic swing beam design, which ensures even distribution of cutting forces for clean and precise cuts. This design minimises wear on the blades and reduces vibration during operation, contributing to consistent cutting quality and improved operator comfort. The robust hydraulic system is engineered for long-term reliability, delivering consistent power and precision across a range of applications.

Built for Durability and Longevity

Durability is a core feature of the BHGS range, with each machine constructed from heavy-duty materials and equipped with a sturdy frame. The robust components and reliable hydraulic system ensure that these guillotines withstand the demands of daily use. With minimal maintenance requirements and a long service life, the BHGS guillotines represent a cost-effective investment for businesses looking to enhance their cutting capabilities.

Ergonomic Design for Operator Comfort

The BHGS guillotines are designed with operator comfort and convenience in mind. The intuitive layout of controls, combined with the clear visibility provided by the high-visibility front guard, ensures that operators can work efficiently and maintain precision. The user-friendly Cybtouch 6 NC controller simplifies operation, reducing the learning curve for new users and allowing them to quickly adapt to the machine’s features. This ergonomic design contributes to a more productive and stress-free work environment.

Versatility for Diverse Cutting Needs

The BHGS range offers the flexibility to meet a variety of cutting requirements, from short lengths to longer sheets and high-volume production runs. The combination of advanced features, including the automatic swing-away back gauge, stainless steel blades, and programmable NC controller, ensures that these machines can handle complex tasks with ease. Optional upgrades and accessories allow businesses to tailor the guillotines to their specific needs, further enhancing their versatility.

Summary: Precision, Safety, and Efficiency

The Morgan Rushworth BHGS hydraulic swing beam guillotine range is an outstanding choice for professionals seeking reliable and high-quality sheet metal cutting equipment. With a strong emphasis on safety, precision, and user-friendly operation, these machines deliver exceptional value for workshops and production facilities of all sizes. Whether cutting short or long lengths, the BHGS guillotines provide the accuracy, efficiency, and durability required to meet today’s demanding production standards. For businesses focused on enhancing their cutting capabilities, the BHGS range offers a dependable and versatile solution.