Mogul Mechanical Engineering Ltd is a fabrication business, based in Cwmbran. They prove a variety of steel erection services, fabricating guarding, platforms, ladders etc, as well as more complicated fabrications. This often includes site work too.

We spoke to Ben Harris, Director, about the various pieces of machinery and service they’ve been supplied by Selmach, including their RVD ER Fibre Laser, Morgan Rushworth ASBR 2050/190 Sheet Rolls, PBR 1250/90 Sheet Rolls, PSR 50/155 Section Roller, HFP 775/30 H-Frame Press, BP 2540/25 Box and Pan Folder, Kepp 150 Belt Grinder, Meyer SR25 Pillar Drill and a Promotech PRO 110 HP Portable Punch.

“I’d recommend Selmach as a one-stop shop to get anything for a fabrication workshop like ourselves.”

How did you hear about Selmach and why did you choose them?

The first time I remember looking at the Selmach website, I heard about it probably through Colin Furze’s YouTube channel. He recently received a delivery of a few of your machines, I think, and he mentioned the name and I got on the website and looked and thought, there’s so many bits of equipment that we need. At the time, we didn’t have much of a machine shop or fabrication workshop. We had a few small machines, but we wanted to invest in new equipment and have everything so that we could do it all in-house.

And so when I saw Colin Furze’s video, it was sort of like a one-stop shop where I could go in and pick all the toys I needed to fill our workshop.

What was the reason(s) that the business considered this machinery in the first place?

The main reason I considered this machinery was that a lot of the work that we did, until we had the machines, we subbed out, which was okay. We got by, but we wanted to grow, so we needed to have the tools at hand to make stuff as and when we needed it without relying on supplier lead times. So once we found Selmach, we opted to look at all of the equipment they had in the showroom, and we liked the look and the branding and the capacities that were available. We could find every machine we needed to be able to satisfy, you know, 99% of what we do.

What machinery have you purchased from Selmach Machinery to solve that?

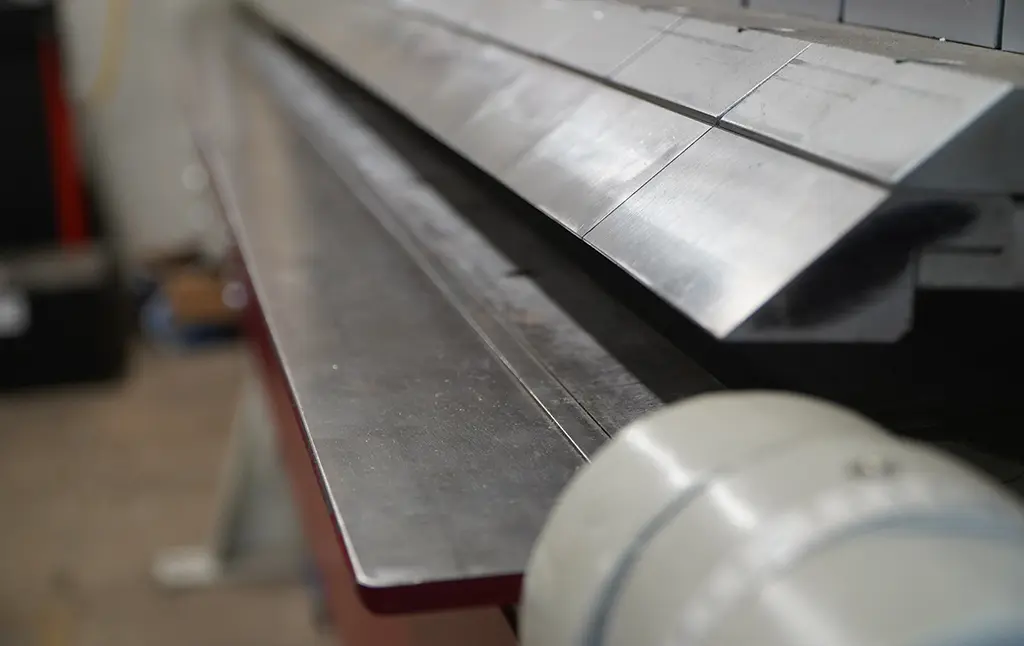

The first time we bought machines, we actually bought quite a few in one go: the small section roller, the 50. We’ve got large sheet rolls and small sheet rolls. So a two metre, seven mm capacity on the large, 3mm, 1.25m capacity on the small rolls, box and pan folder, 2.5m by 2.5 mm. We purchased belt grinders, pillar drill, a 30 tonne press, portable punch. The most recent delivery we received is the laser. We’ve been playing with that a lot in the last few months and getting that set up, and we’ve had a lot of fun with that. And we’ve currently got another machine on order, which we’re waiting for delivery and are excited for, which is a larger section roller, HSR-3/100, which, although our little one has done us well— we’ve done a lot of work on the small one— we now have got the next step up for bigger work.

How has the machinery helped the business?

The machinery’s worked out really great. We’ve had no issues at all with any of the equipment. It’s been the right tools for what we needed. There’s always a bigger machine you want to get, but you do need the small machines to do some of the small stuff as well. And I think that with the machines we’ve had, we’ve had a chat with the guys at Selmach and we’ve been given good advice on what we should be having— the sizes and capacities we need for the type of work we do.

So it’s worked out really great, and we’ve had no issues at all.

How was the experience with Selmach while you were being quoted / advised and delivered?

The experience has been great. From an advice point of view, we’ve had lots of opportunities to visit the showroom at Selmach and we’ve discussed the type of work we do. So we’re always advised the right machine for us. There’s always a cost to consider as well, so we’re typically given a range of options, varying costs, and then we can look at our budget. It’s worked out quite well in terms of the advice we’ve had. We’ve got a good relationship with the sales guys, the quotes have been pretty good, and we were able to negotiate a fair deal on a lot of the equipment.

What about aftercare and service?

The aftercare and service has been great. There’s always someone at the end of the phone ready to help out and offer advice if you’ve got an issue. We have had some minor, minor little teething issues on one or two things, but they’ve been solvable within a phone call. There’s always somebody that’s able to pop down when you do have a real issue. I’ve worked with Dave on the laser in particular, where we’ve had an issue and they’ve been just down the road— they pop down to help out and we’re able to set up the machine when I’m struggling to achieve something. There’s someone there to call that I can rely on that’s going to come in and solve the problem and set me on the right path. And again, we keep in communication about potential future machines we want to buy because of the level of service that we’ve received.

Any future machinery considerations?

For the future, we want to upgrade some of our other kit, our older kit that isn’t necessarily from Selmach, but we want to upgrade to higher capacities, bigger, better, and probably go bigger on the sheet rolls. Possibly our eyes are on a lathe in the future as well.

Would you recommend Selmach and our machinery?

Yeah, I’d absolutely recommend the machinery to anybody who’s looking at the Morgan Rushworth machinery or the RVD laser or anything that Selmach produce, because everything we’ve received so far has been of good quality. And as I mentioned before, the aftercare is there if you have any issues and there’s always someone that you can share your work with, and maybe they’ll keep in touch with you if they’ve got future machinery and explain what the latest machines that they’ve got to sell as well.

So I’d recommend Selmach as a one-stop shop to get anything for a fabrication workshop like ourselves.

If you’d like to find out more about the machinery supplied to Mogul, click the links below.

Morgan Rushworth ASBR 2050/190 Sheet Rolls

Morgan Rushworth PBR 1250/90 Sheet Rolls

Morgan Rushworth PSR 50/155 Section Roller

Morgan Rushworth HSR-3 100/315 Section Roller (Due for delivery shortly)

Morgan Rushworth HFP 775/30 H-Frame Press

Published 11th June 2025