Morgan Rushworth SBR Powered Bending Roll

The Morgan Rushworth SBR Powered Bending Rolls are designed for medium- to heavy-duty applications, handling materials from 1.0mm to 5.0mm with bending lengths up to 2050mm. The rugged heavy-duty cast iron frame ensures a long working life and exceptional stability during operation.

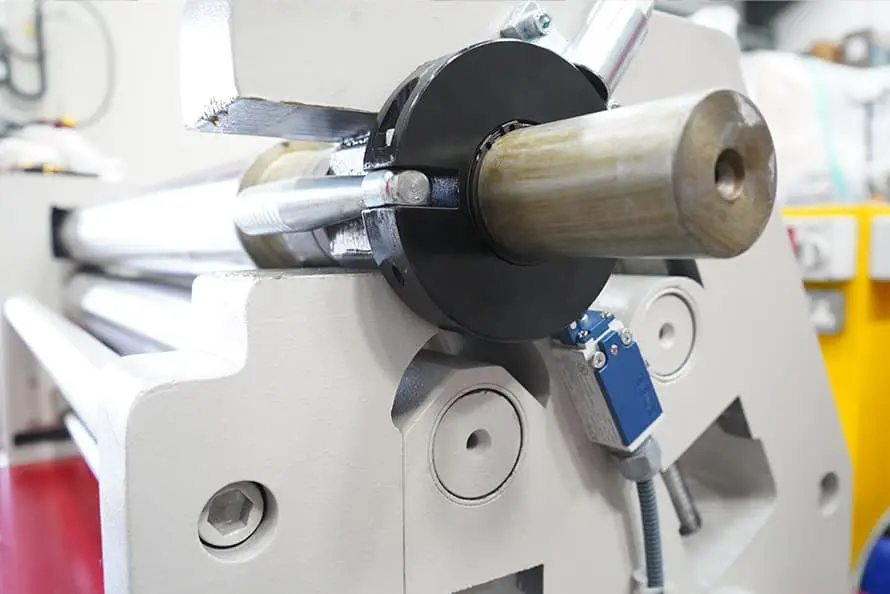

Featuring an asymmetric roll configuration, these machines ensure precise pre-bending and smooth results while minimising flat spots. The powered top roll slip mechanism simplifies the removal of cylindrical components, boosting efficiency and workflow in various industrial tasks.

| MODEL | STOCK CODE | BENDINGLENGTH | PRE BENDING | MAX THICKNESS | TOP ROLL DIA. | MOTOR | LENGTH | HEIGHT | WIDTH | WEIGHT |

| mm | mm | mm | mm | kW | mm | mm | mm | kg | ||

| SBR 1050/110 | M3017 | 1050 | 4 | 5 | 110 | 2.2 | 1820 | 1150 | 850 | 1080 |

| SBR 1050/130 | M3018 | 1050 | 5 | 6 | 130 | 2.2 | 1820 | 1200 | 900 | 1220 |

| SBR 1250/110 | M3019 | 1250 | 3.5 | 4 | 110 | 2.2 | 2020 | 1150 | 850 | 1150 |

| SBR 1250/120 | M3020 | 1250 | 4 | 4.5 | 120 | 2.2 | 2020 | 1150 | 850 | 1250 |

| SBR 1250/140 | M3021 | 1250 | 5 | 6 | 140 | 2.2 | 2020 | 1200 | 900 | 1365 |

| SBR 1550/110 | M3022 | 1550 | 3 | 3.5 | 110 | 2.2 | 2320 | 1150 | 850 | 1250 |

| SBR 1550/130 | M3023 | 1550 | 4 | 4.5 | 130 | 2.2 | 2370 | 1200 | 900 | 1360 |

| SBR 2050/110 | M3024 | 2050 | 2 | 3 | 110 | 2.2 | 2820 | 1150 | 850 | 1350 |

| SBR 2050/130 | M3025 | 2050 | 3 | 4 | 130 | 2.2 | 2820 | 1200 | 900 | 1480 |

| SBR 2050/140 | M3026 | 2050 | 4 | 4.5 | 140 | 2.2 | 2820 | 1200 | 900 | 1530 |

Capacities are given for 250 N/mm² plate yielding strength

Features

- Top roll to slip

- Powered bending

- Cone bending

- Crowned Rolls

- Powered top and bottom roll with foot operated forward and reverse control

- Brake motor

- Manually adjusted side roll for up and down translation

- Manual pinching of bottom roll

Options

- With / Without body cover (PBR)

- Induction hardened rolls

- Parallel Rolls

- Powered side roll up and down translation

- DRO for side roll position

Morgan Rushworth SBR Powered Bending Rolls

The Morgan Rushworth SBR Powered Bending Rolls are a versatile and robust solution for medium- to heavy-duty sheet metal bending tasks. Built to handle material thicknesses ranging from 1.0mm to 5.0mm, with a maximum bending length of 2050mm, these machines combine precision engineering with exceptional durability. Designed to deliver professional-grade results, the SBR range is a reliable choice for workshops and fabrication facilities requiring consistent performance across a range of applications.

At the heart of the SBR models is a rugged cast iron frame. This heavy-duty construction ensures the machine’s stability and longevity, even under demanding workloads. The durable frame provides a solid foundation for precise and repeatable bending, making the SBR range an excellent investment for businesses seeking equipment that can handle challenging tasks while maintaining accuracy over time.

Advanced Asymmetric Roll Configuration

The asymmetric roll configuration is one of the defining features of the Morgan Rushworth SBR Powered Bending Rolls. This design enhances the machine’s functionality by providing pre-bending capability, which eliminates flat spots at the edges of the material. By pre-bending the sheet metal before rolling, the machine ensures smoother, more uniform bends and a higher-quality finish.

This feature is particularly important for applications requiring precision and consistency, such as the production of structural components, cylindrical shapes, or other curved profiles. The asymmetric configuration also simplifies the bending process, reducing the need for complex manual adjustments and ensuring that even less experienced operators can achieve professional results.

Powered Top Roll Slip Mechanism

Another standout feature of the SBR range is the powered top roll slip mechanism. This allows the top roll to move outward, making it easy to remove finished cylindrical components. This feature is especially beneficial when working with fully enclosed shapes or tightly rolled materials, as it streamlines the extraction process and reduces downtime.

The powered top roll slip mechanism improves overall workflow efficiency by enabling operators to transition between tasks quickly and smoothly. Whether working on large-scale production or smaller, custom projects, this feature enhances productivity and ensures that the machine remains versatile and user-friendly.

Applications Across Industries

The Morgan Rushworth SBR Powered Bending Rolls are designed to meet the needs of a variety of industries. Their ability to handle thicker materials and longer bending lengths makes them ideal for tasks such as:

- Structural Fabrication: Bending beams, panels, and frames for construction projects.

- Automotive Manufacturing: Producing heavy-duty vehicle components, including chassis parts and reinforcements.

- Aerospace Engineering: Forming precise and durable metal sections for aircraft components.

- Industrial Equipment: Creating cylindrical and conical shapes for machinery and equipment.

- HVAC Systems: Rolling parts for ducting, piping, and ventilation systems.

The versatility of the SBR range makes it suitable for workshops and fabrication facilities of all sizes. Whether working on large-scale industrial projects or smaller custom applications, the SBR models deliver reliable performance and exceptional results.

Ease of Use and Efficiency

Despite their advanced capabilities, the SBR Powered Bending Rolls are designed with user-friendliness in mind. The controls are straightforward and intuitive, enabling operators to set up and adjust the machine quickly and efficiently. This ease of use ensures that even less experienced users can operate the machine confidently and achieve precise, high-quality results.

The powered operation of the SBR range significantly reduces manual effort, allowing operators to focus on accuracy and productivity. Combined with the asymmetric roll configuration and top roll slip mechanism, these features make the SBR range one of the most efficient and versatile options available for medium- to heavy-duty bending tasks.

Durability and Reliability

Morgan Rushworth has a long-standing reputation for producing high-quality metalworking equipment, and the SBR range is no exception. Constructed from high-grade materials and engineered to exacting standards, these machines are built to withstand the rigours of daily use while maintaining their performance and precision.

The heavy-duty cast iron frame not only ensures stability during operation but also minimises wear and tear, reducing maintenance requirements and extending the machine’s service life. This durability makes the SBR range a cost-effective choice for workshops looking to invest in reliable, long-term equipment.

Why Choose the SBR Range?

The Morgan Rushworth SBR Powered Bending Rolls stand out for their combination of power, precision, and ease of use. Their ability to handle a wide range of material thicknesses and lengths, coupled with features like the asymmetric roll configuration and powered top roll slip mechanism, ensures they deliver consistent, professional results across various applications.

Compared to lighter-duty machines, the SBR range offers the strength and durability required for more demanding projects, making them a valuable addition to any workshop. Whether you’re working on industrial equipment, structural fabrication, or precision aerospace components, the SBR range provides the tools needed to achieve exceptional results.

Conclusion

The Morgan Rushworth SBR Powered Bending Rolls are a versatile, durable, and high-performance solution for medium- to heavy-duty sheet metal bending tasks. With their robust cast iron frame, advanced asymmetric roll configuration, and powered top roll slip mechanism, these machines combine reliability, precision, and ease of operation to meet the needs of modern workshops.

Ideal for industries such as construction, automotive, and industrial manufacturing, the SBR range delivers consistent results and exceptional value. Backed by Morgan Rushworth’s reputation for quality and innovation, the SBR Powered Bending Rolls are an investment in long-term productivity and reliability, ensuring high-quality performance for years to come.